Cotton gin capable of automatically feeding cotton and collecting finished products

A technology of finished product collection and ginning machine, applied in the direction of separating plant fibers from seeds, etc., can solve the problems of low efficiency, labor-intensive, cost-increasing, etc., and achieve the effects of ease of use, time saving, and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

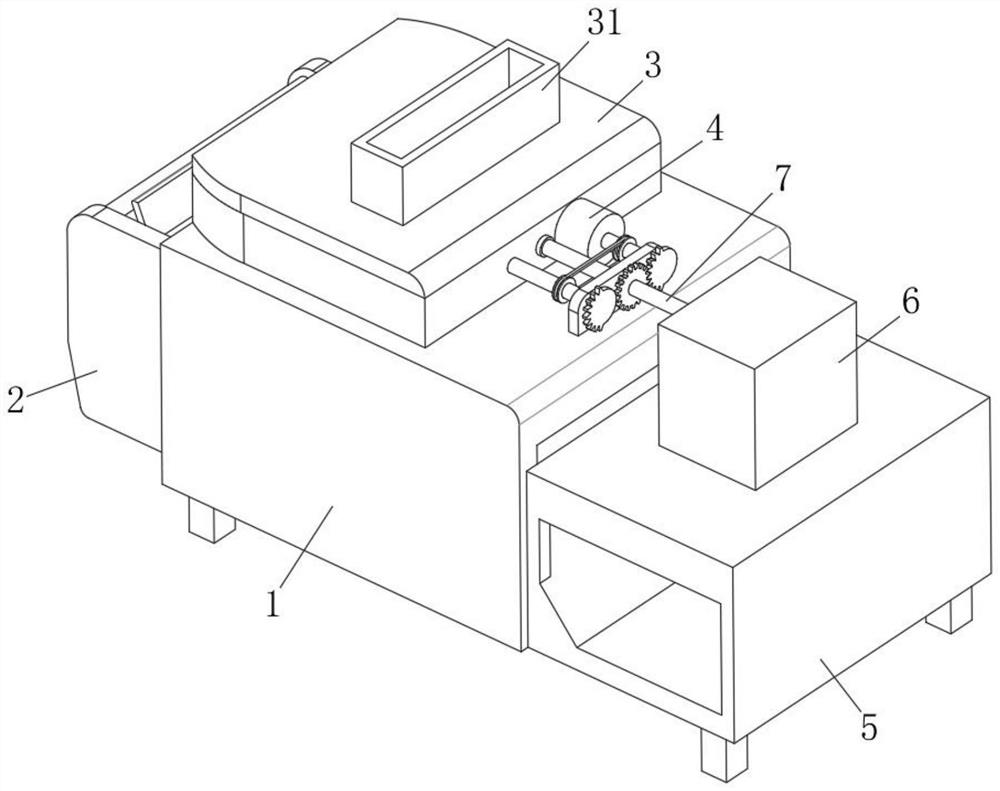

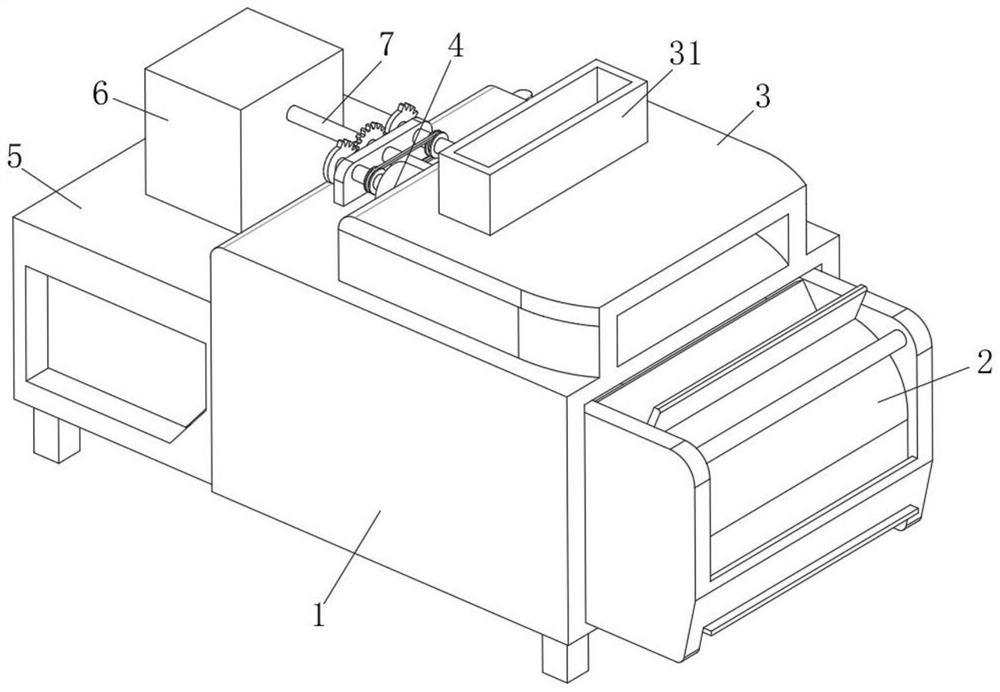

[0031] refer to Figure 1-6 , a cotton gin that automatically sends cotton and collects finished products, including a box body 1, a processing module 2 is fixedly installed at one end of the box body 1, which is convenient for processing cotton, and a material bin 3 is fixedly installed on the upper surface of the box body 1, for To facilitate the storage of cotton, the upper surface of the material bin 3 is connected with a feeding port 31. In order to facilitate the entry of cotton from the outside into the inside of the material bin 3, the inside of the material bin 3 is provided with a feeding assembly 4, and the other end of the box body 1 is fixedly installed with a The discharge box 5 is convenient for the treated cotton to go to the outside. The upper surface of the discharge box 5 is fixed with a protective box 6. In order to protect the parts from damage, the inside of the protective box 6 is provided with a push assembly 7;

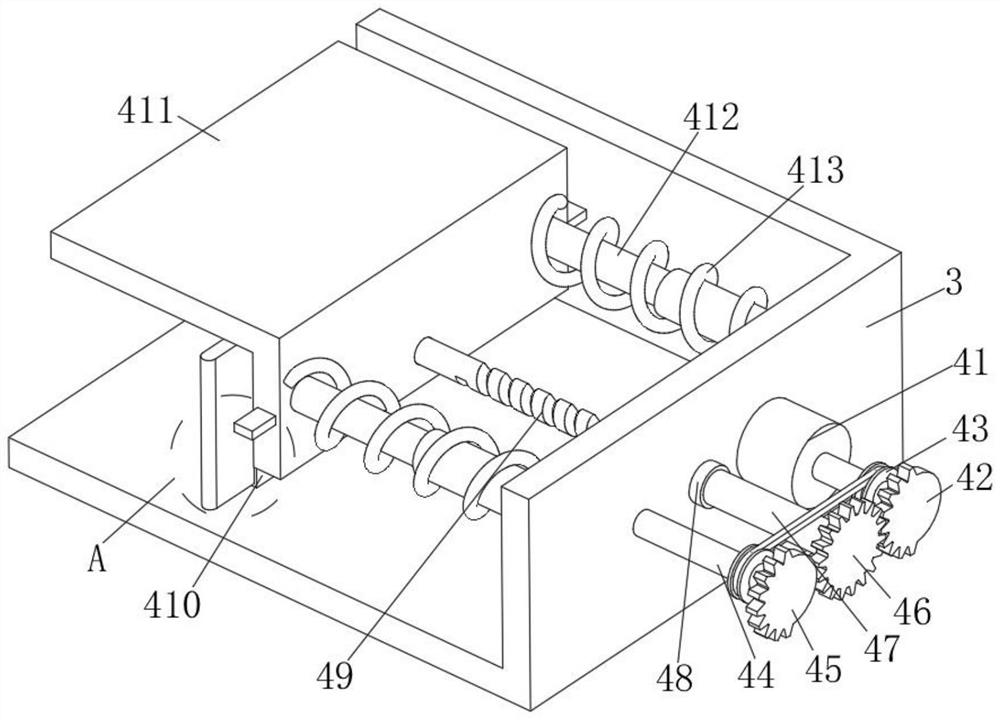

[0032] The feeding assembly 4 includes ...

Embodiment 2

[0036] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the inner wall of the sleeve 47 is provided with threads, and the inner wall of the sleeve 47 is engaged with the outer surface of the screw rod 49 .

[0037] In this embodiment, the sleeve 47 is meshed with the screw rod 49 , so that the sleeve 47 can drive the screw rod 49 to move back and forth when the sleeve 47 rotates, thereby driving the first push plate 410 and the baffle plate 411 to move.

Embodiment 3

[0039] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, both sides of the first push plate 410 are provided with grooves 4101, and the inner walls of the two groups of grooves 4101 are fixedly installed with two sets of first springs 4102. One end of each group of first springs 4102 that is far away from each other is fixedly connected with a telescopic plate 4103 , and the telescopic plate 4103 is slidably matched with the groove 4101 .

[0040] In this embodiment, by setting the first spring 4102 , the contracted telescopic plate 4103 will return to the original position under the action of the first spring 4102 in the process of returning to the original position following the first push plate 410 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com