Mobile-cowl thrust reverser comprising thrust-reduction mechanism that is independent of mobile cowl

A thrust reverser, thrust reversal technology, applied in engine control, engine function, machine/engine, etc., can solve problems such as not allowing safe adjustment of propulsion components, large aerodynamic effects of deploying the reverser, etc. The effect of alleviating airspace congestion, reducing fuel consumption and reducing thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

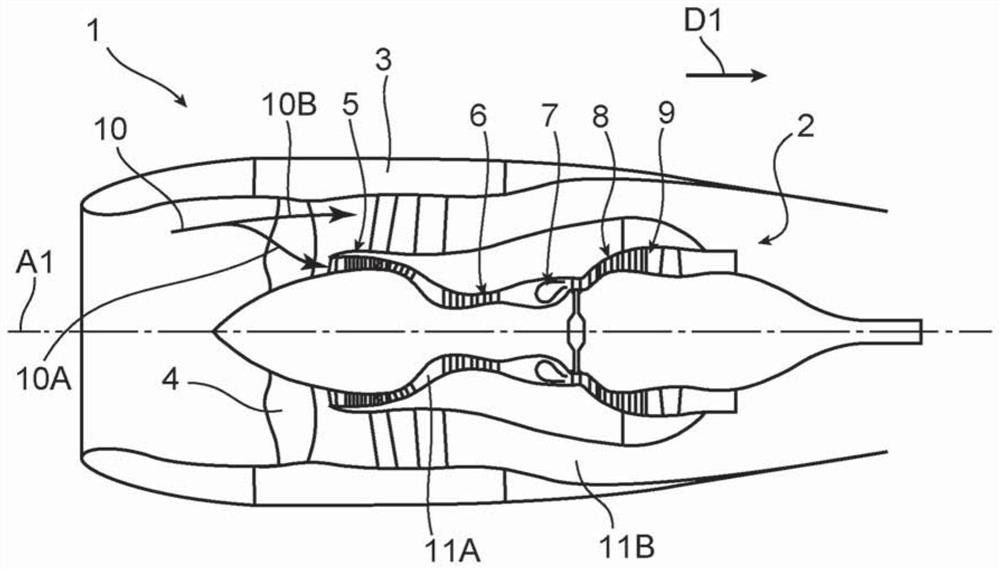

[0041] exist figure 1 In , an aircraft propulsion assembly 1 comprising a turbine engine 2 rectified by a nacelle 3 is shown. In this example, the turbine engine 2 is a twin-body twin-flow jet engine.

[0042] In the following, the terms "upstream", "downstream", "front" and "rear" are defined with respect to the direction D1 of the air flow through the propulsion assembly 1 when the propulsion assembly 1 is propelled.

[0043]The jet engine 2 has a longitudinal central axis A1, the various components of the jet engine, in this case from upstream to downstream of the jet engine 2, the fan 4, the low pressure compressor 5, the high pressure compressor 6, the combustion chamber 7, the high pressure turbine 8 and the low pressure The turbine, 9, extends around this longitudinal central axis. The compressors 5 and 6, the combustor 7 and the turbines 8 and 9 form a gas generator.

[0044] Normally, during operation of such a jet engine 2, an air flow 10 enters the propulsion as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com