Oral medicine lozenge manufacturing equipment and manufacturing method thereof

A technology for manufacturing equipment and manufacturing methods, which can be applied to other household appliances, devices that make medicines into special physical or ingestible forms, household components, etc., which can solve the problem of high overall costs, the inability to reduce the unit price of pills, and the inability to meet demand at any time. Adjusting the volume of tablets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

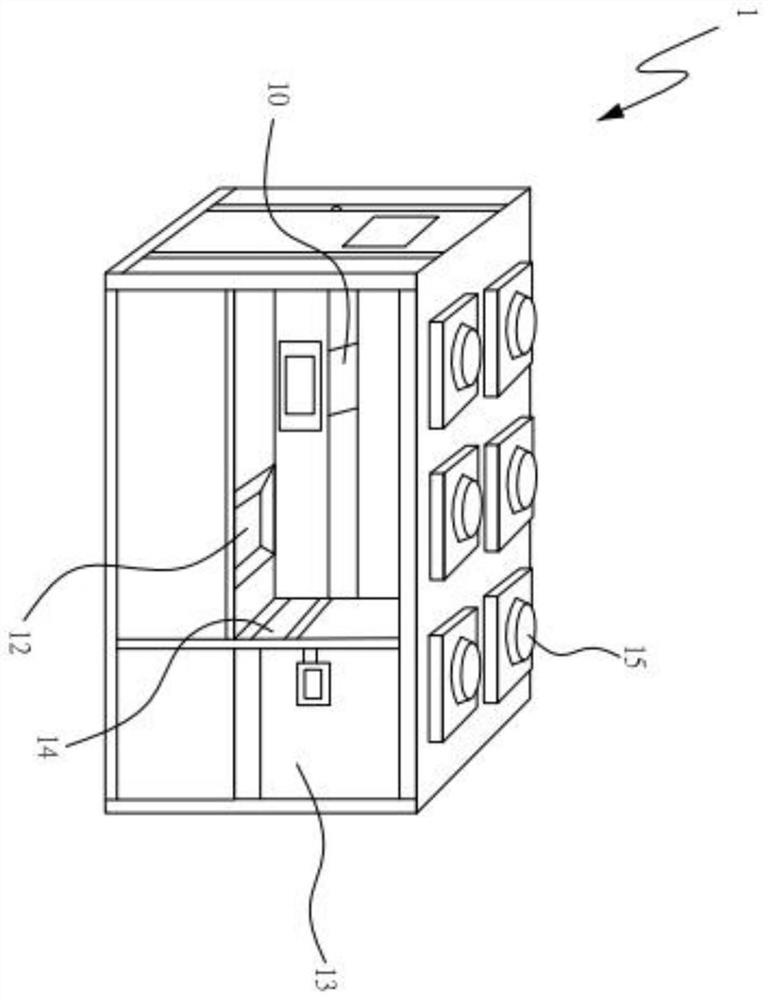

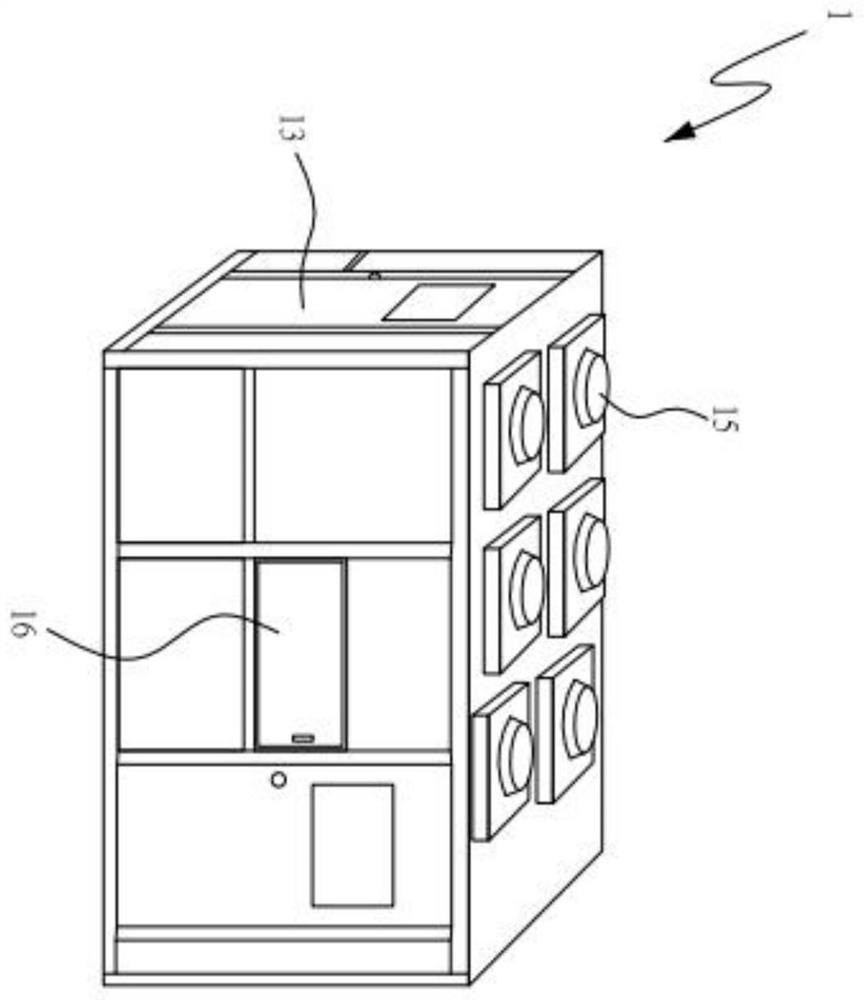

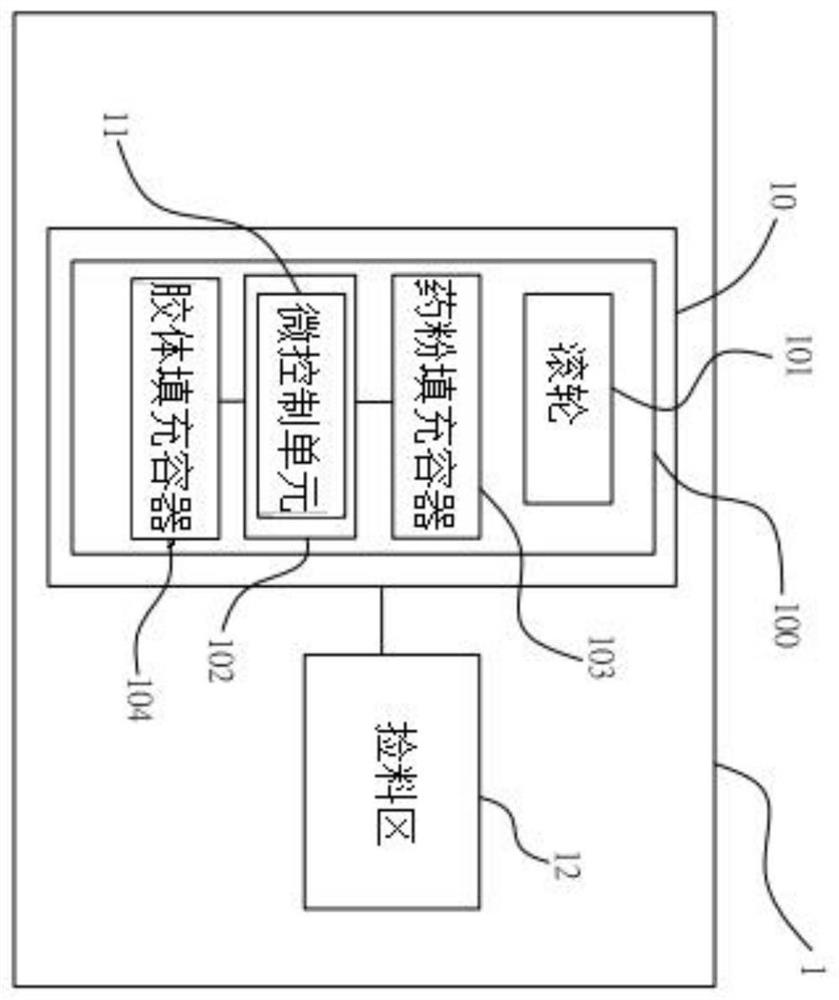

[0037] see figure 1 , figure 2 , Figure 3A , Figure 3B , Figure 3C , is the three-dimensional schematic diagram and block diagram of the first embodiment of the oral tablet manufacturing equipment of the present invention and the block diagram and schematic diagram of the piezoelectric nozzle. As shown in the figure, an oral tablet manufacturing equipment 1 includes a drug tablet manufacturing area 10. A micro-control unit 11 and a material picking area 12, the tablet manufacturing area 10 includes a tablet spraying device 100, the tablet spraying device 100 has a roller 101 and a piezoelectric nozzle 102, a powder filling container 103 communicates with the piezoelectric nozzle 102, the powder filling container 103 holds a plurality of powders, and the powders are sprayed through the piezoelectric nozzle 102, and then the powder is pressed and flattened by the roller 101 operation, to make the powder into a tablet, in addition, the tablet spraying device 100 has a col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com