Mupirocin ointment and preparation method thereof

A technology of mupirocin and ointment, which is applied in the field of drug manufacturing, can solve the problems affecting the experience and curative effect of patients, uneven distribution of active ingredients, unsatisfactory drug efficacy, etc. The effect of small content change and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A Most Star Ointment: Including the following weight materials: 30 Mororo Star, 300 polyethylene glycol 3350, 700 parts of polyethylene glycol 400, 20 parts propylene glycol, 10 龙 褐 萃 液, 8 Wishferome extract, 12 parts of butyl hydroxylholder ether, 11 vitamin E oil; the dragon blood brown extract is grinding dragon blood, over 50 mesh sieve, then loaded into the extraction of supercritical extracts In the kettle, use supercritical Co 2 For solvent, the extraction pressure is 18 MPa, the temperature is 61 ° C, the extraction time is 3 h, CO 2 The flow rate is 25 kg / h to perform supercritical extraction, which is a dragon platelet extract; the purple chrysanthemum extract is the upper portion of the fresh flower bud, which is pulverized, the purple car cone grazage, and the mass concentration is 90% ethanol heating to 80 ° C. After refluxing extraction 1 h, the mass volume ratio of water cone chrysanthemum and ethanol was 2:50, filtered, and the purple chrysanthemum extract...

Embodiment 2

[0024] A Most Star Ointment: including the following weight materials: 70 Mororo stars, 400 parts of polyethylene glycol 3350, 800 parts of polyethylene glycol 400, 30 parts propylene glycol, 30 龙 血 褐 萃 液, 22 Sex extract, 33-parts butylhydroxylholder ether, 28 vitamin E oil; the dragon blood brown extract is grinding dragon blood, over 80 mesh sieve, then loaded into supercritical extracts In the kettle, use supercritical Co 2 For solvent, the extraction pressure is 25 MPa, the temperature is 80 ° C, the extraction time is 5 h, CO 2 The flow rate is 35 kg / h to perform supercritical extraction, which is a dragon platelet extraction liquid; the purple chrysetryromile extract is part of the fresh flower buds, pulverized, golficular grazing, and adding a mass concentration of 95% to 100 ° C. After refluxing extraction of 5 h, the mass volume of water cone chrysanthemum and ethanol was 5:50, filtered, and the purple chrysanthemum extract was separated.

Embodiment 3

[0026] A Most Star Ointment: Including the following weight of the material: 50 Morros, 350 parts of polyethylene glycol 3350,750 parts polyethylene glycol 400, 25 parts propylene glycol, 20 龙 龙 褐 液, 15 Wishferome extract, 22 servant hydroxyapoxyl ether, 20 vitamin E oil; the dragon blood brown extract is grinding dragon blood, over 70 mesh sieve, then loaded into the extraction of supercritical extracts In the kettle, use supercritical Co 2 For solvent, the extraction pressure is 22 MPa, the temperature is 70 ° C, the extraction time is 4 h, CO 2 The flow rate is 30 kg / h for supercritical extraction to obtain a dragon blood brown extract; the purple chrysetryromile extract is a fresh flower bud, which is pulverized, and the purple glycery, and the mass concentration of 92% is heated to 90 ° C. After refluxing extraction 3 h, the mass volume of water cone chrysanthemum and ethanol is 3:50, filtered, and the purple chrysanthemum extract is separated.

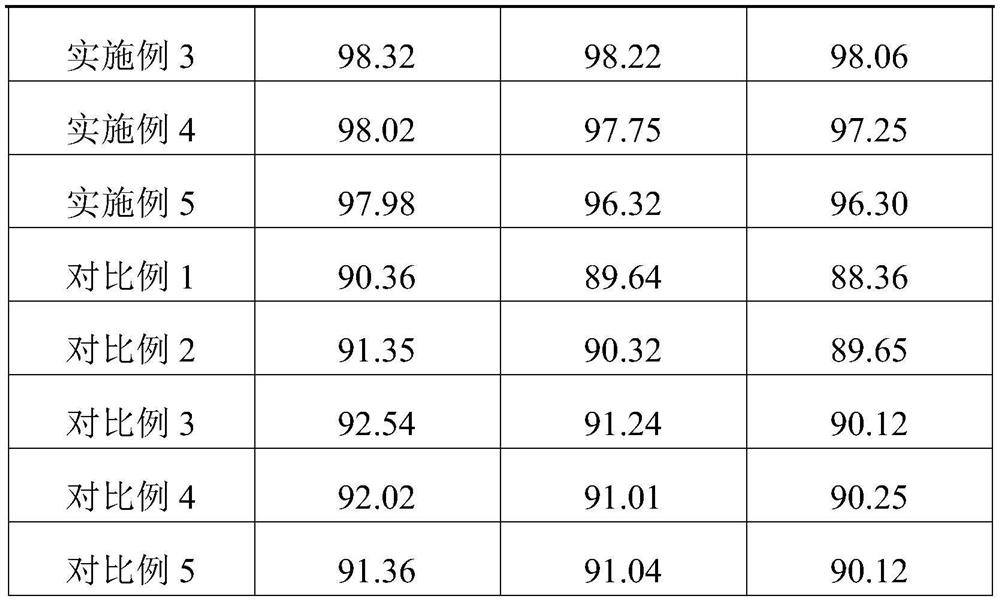

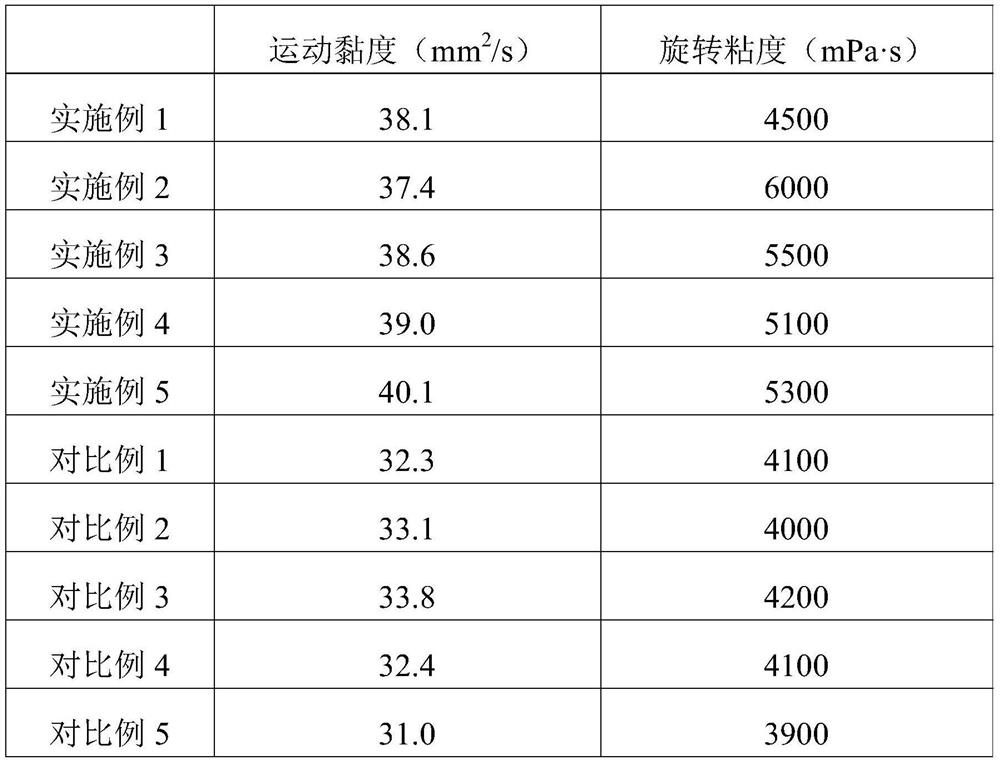

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com