Patents

Literature

31 results about "Polyethylene glycol product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

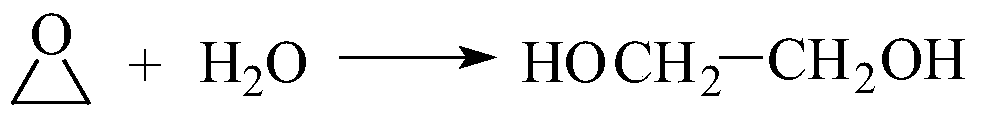

The production of polyethylene glycol was first reported in 1859. Both A. V. Laurence and Charles Adolphe Wurtz independently isolated products that were polyethylene glycols. Polyethylene glycol is produced by the interaction of ethylene oxide with water, ethylene glycol, or ethylene glycol oligomers.

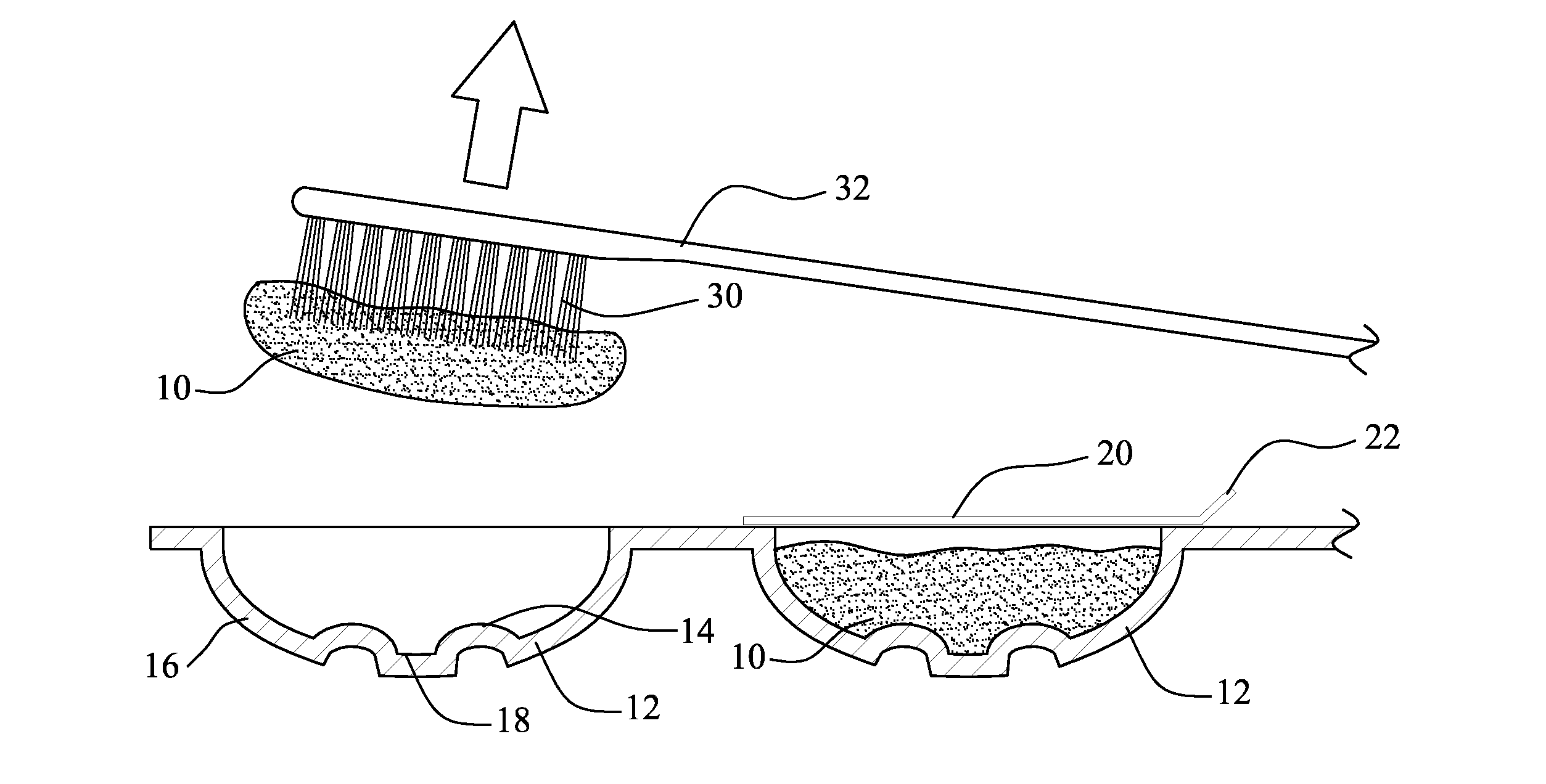

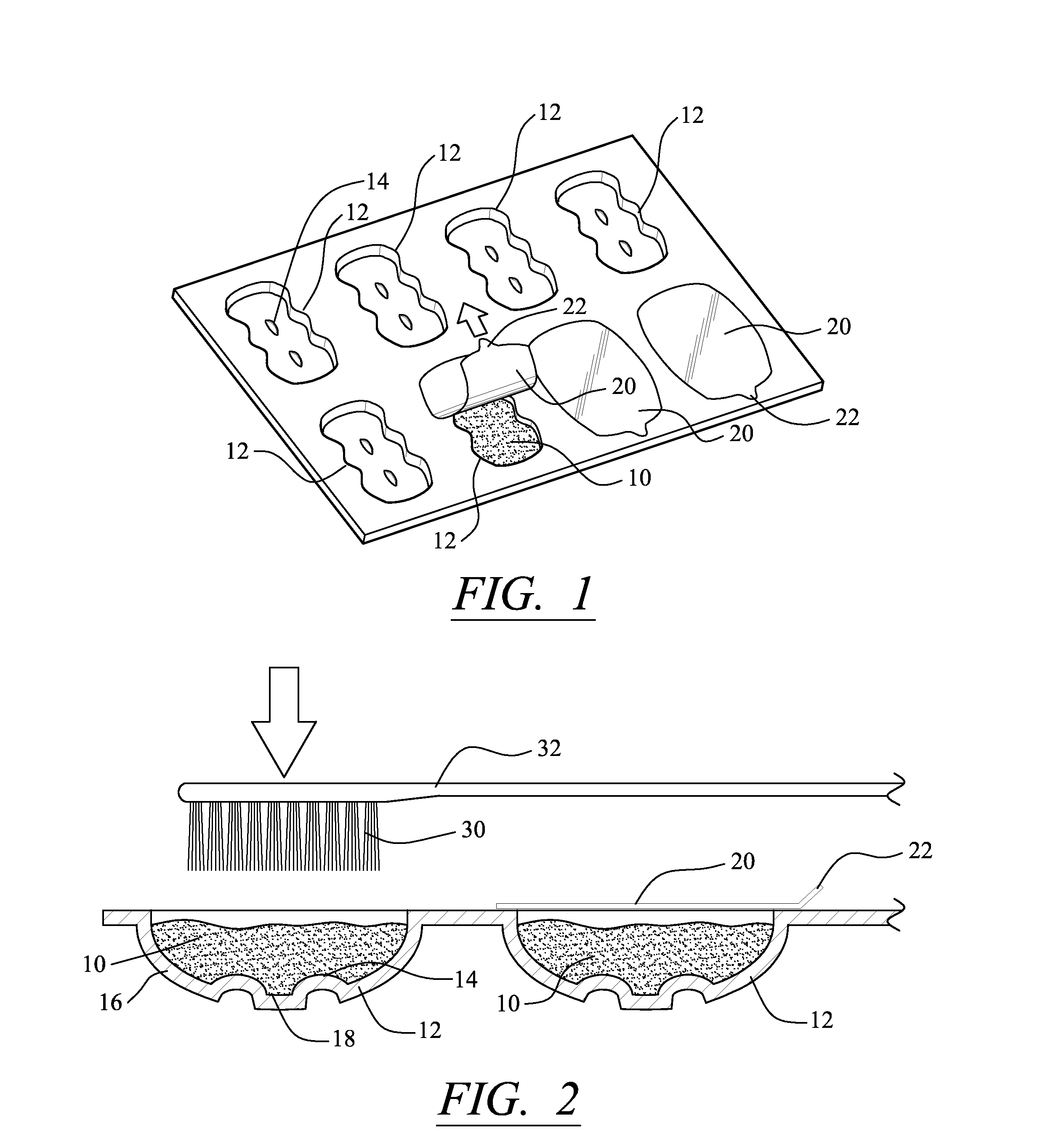

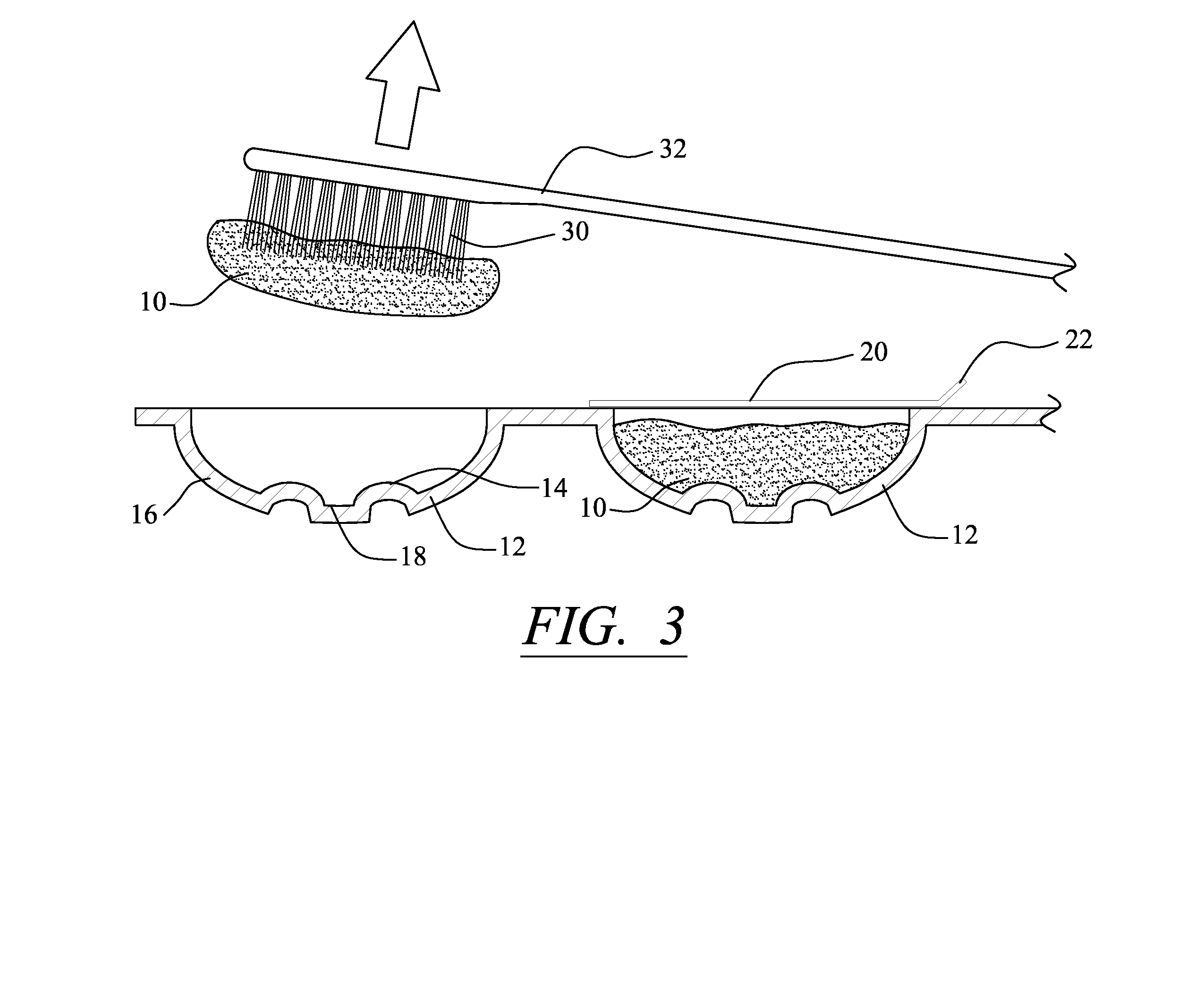

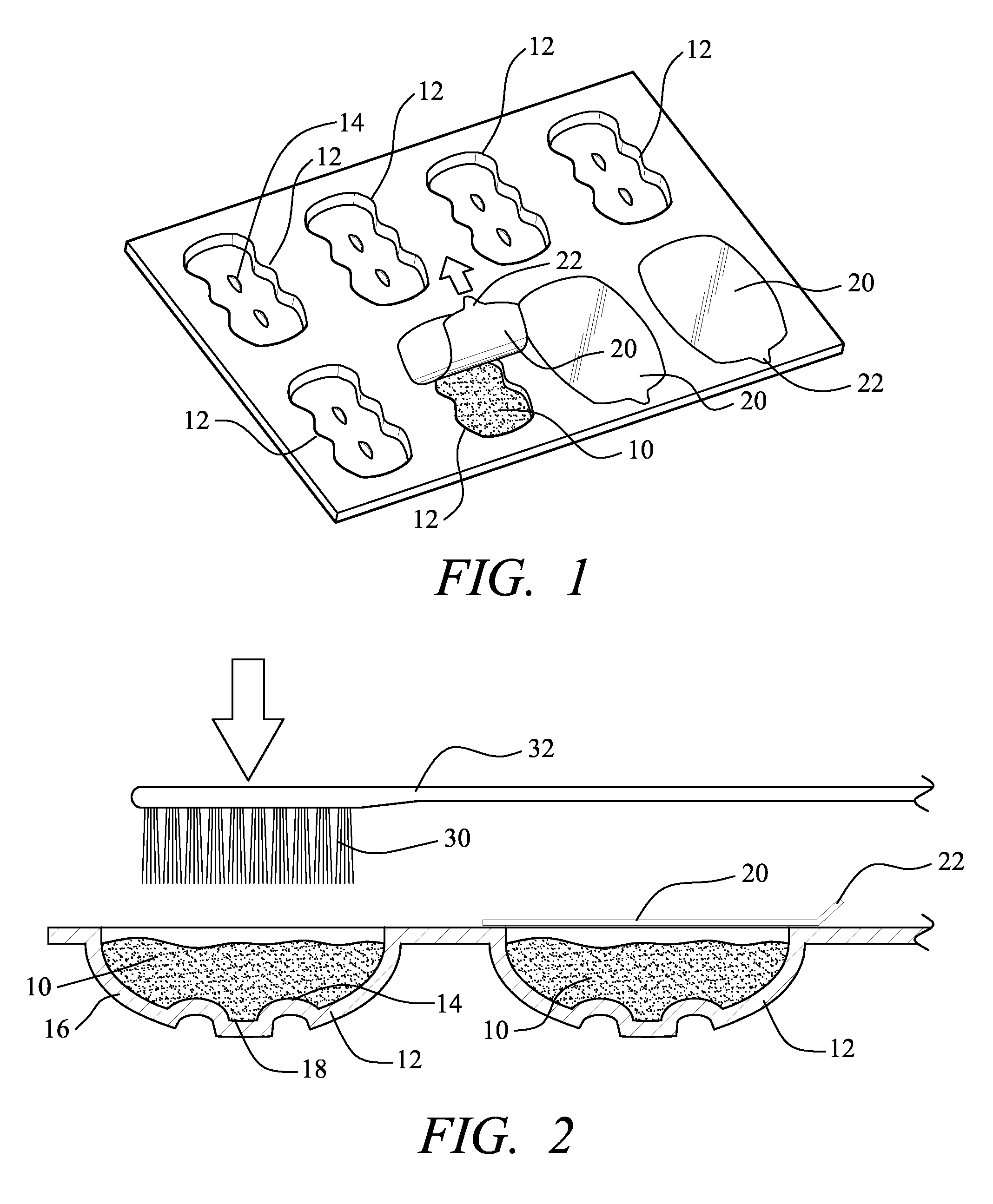

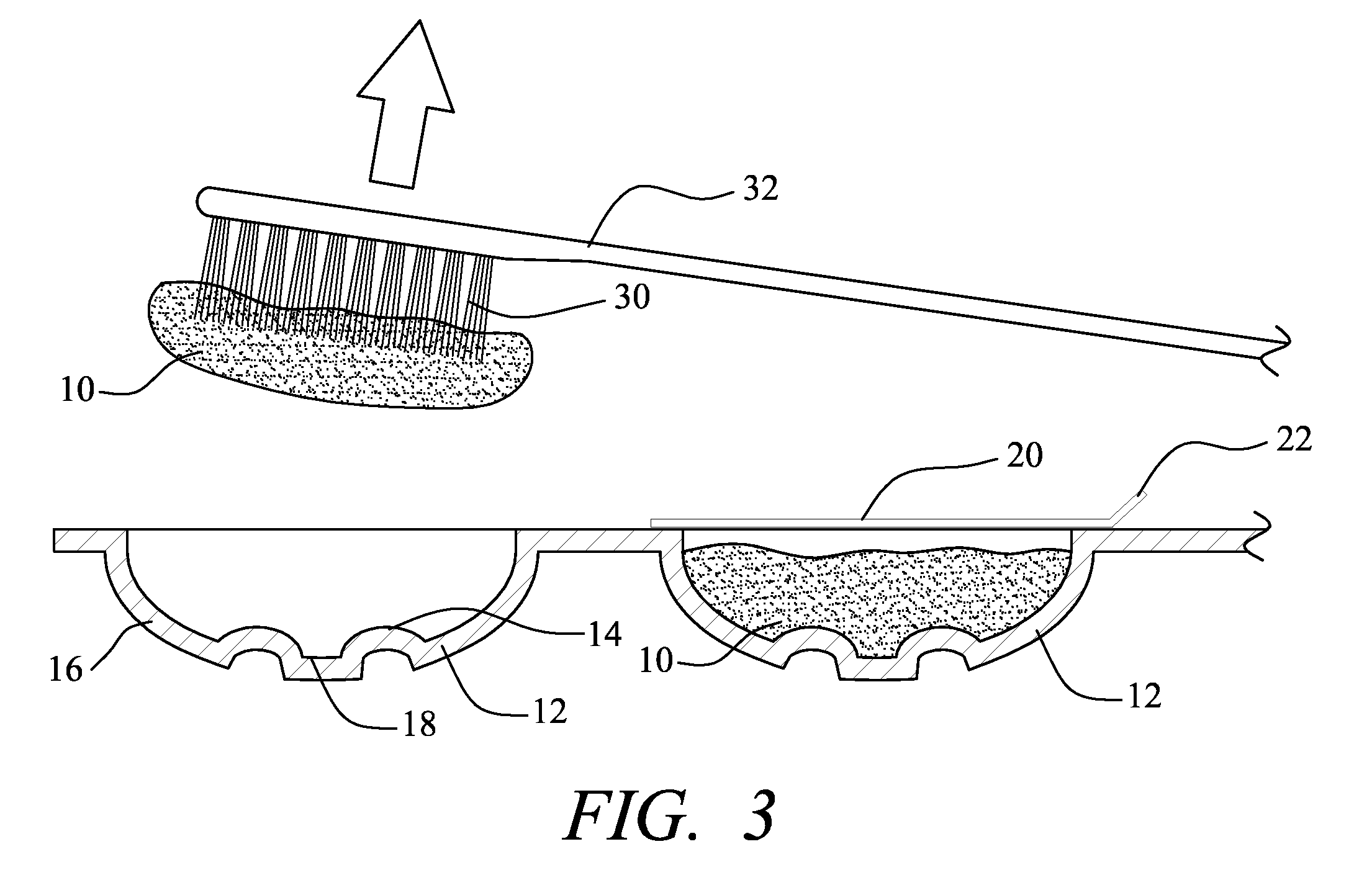

Toothpaste composition and method of applying a single serving of toothpaste to a toothbrush

A toothpaste composition includes different combinations of konjac gum and / or agar-agar, alginates, gelatin, pectin, xanthan, tara gum, gum arabic, carrageenan, celluloses, gellan gum, guar gum, inulin, konjac, locust bean gum, pectin, tragacanth, xanthan, polyethylene glycol-3350, xylitol, calcium carbonate, stevia, quillaja, liquid bioflavonoid extract, and water. The toothpaste composition produces a toothpaste product that maintains its shape prior to being used for brushing one's teeth and is preferably formed into a single serving of toothpaste stored in an open-top compartment having a removable protective film. A method of applying a single serving of toothpaste to a toothbrush includes the steps of pressing the bristles of a toothbrush against the single serving of toothpaste so that the single serving of toothpaste clings or otherwise adheres to the bristles, and subsequently pulling the toothbrush away from the compartment for brushing one's teeth.

Owner:SCHAPIRO EDWARD +4

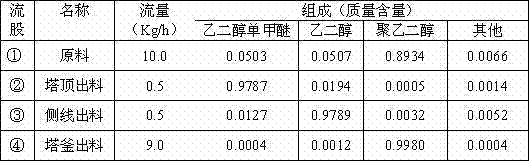

Method for recovering polyethylene glycol and silicon carbide from silicon crystal cutting waste liquid

The invention discloses a method for recovering polyethylene glycol and silicon carbide from silicon crystal cutting waste liquid. The method comprises the following steps of: A) diluting the cutting waste liquid with water and stirring, extracting metal scarp iron from the mixture by using a magnet after ultrasonic processing; B) adding a flocculating agent into the mixture for centrifugal separation; C) diluting solid I with water, adding sodium hydroxide into the solution, heating the mixture to perform reaction, cleaning the mixture with the water, adding an acid into the mixture, and cleaning the mixture with the water to obtain a crude silicon carbide product; D) performing centrifugal separation on the crude silicon carbide product, and drying the crude product to obtain a finished silicon carbide product; and E) filtering the liquid, heating, evaporating and dehydrating the filtered liquid to obtain a finished polyethylene glycol product. In the scheme, the mixture is diluted first, so the recovery rate of the polyethylene glycol is improved. The silicon and iron content of the crude silicon carbide product and the consumption level of the acid and alkali are reduced by ultrasonic processing and iron removal. The method has the characteristics of reasonable process, environmental protection and the like.

Owner:ZHEJIANG YUANSHENG SILICON MATERIALS

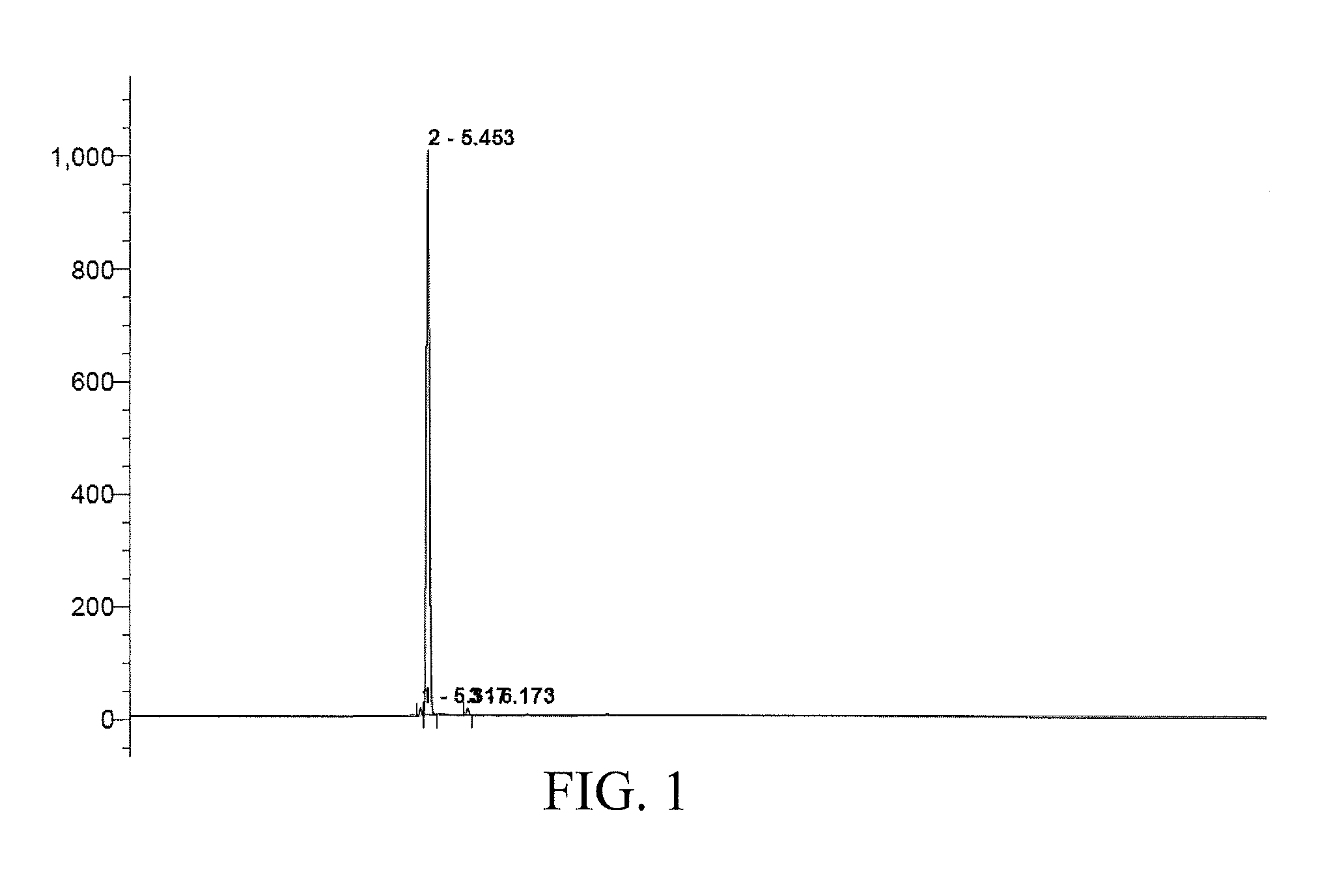

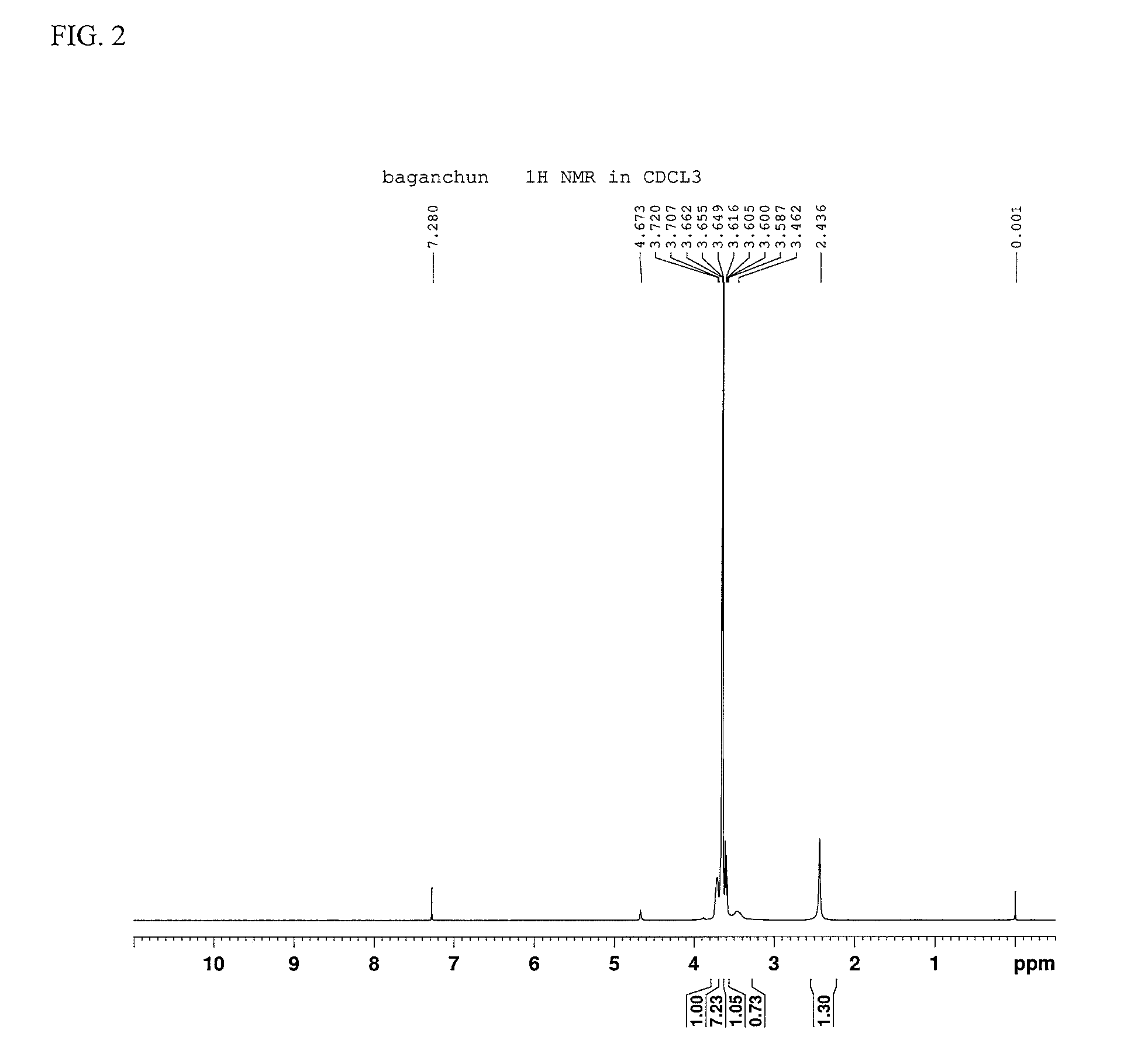

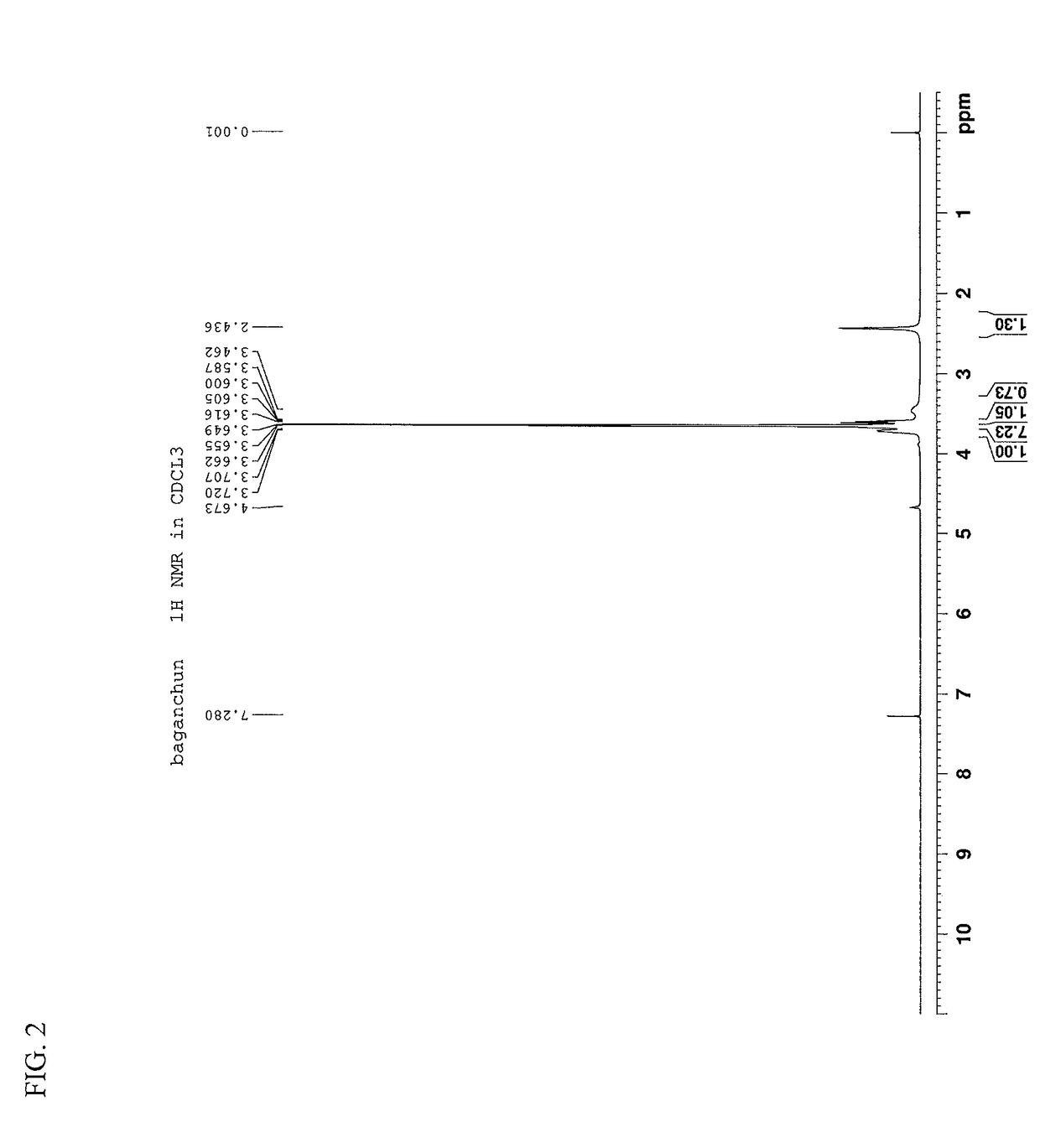

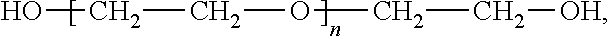

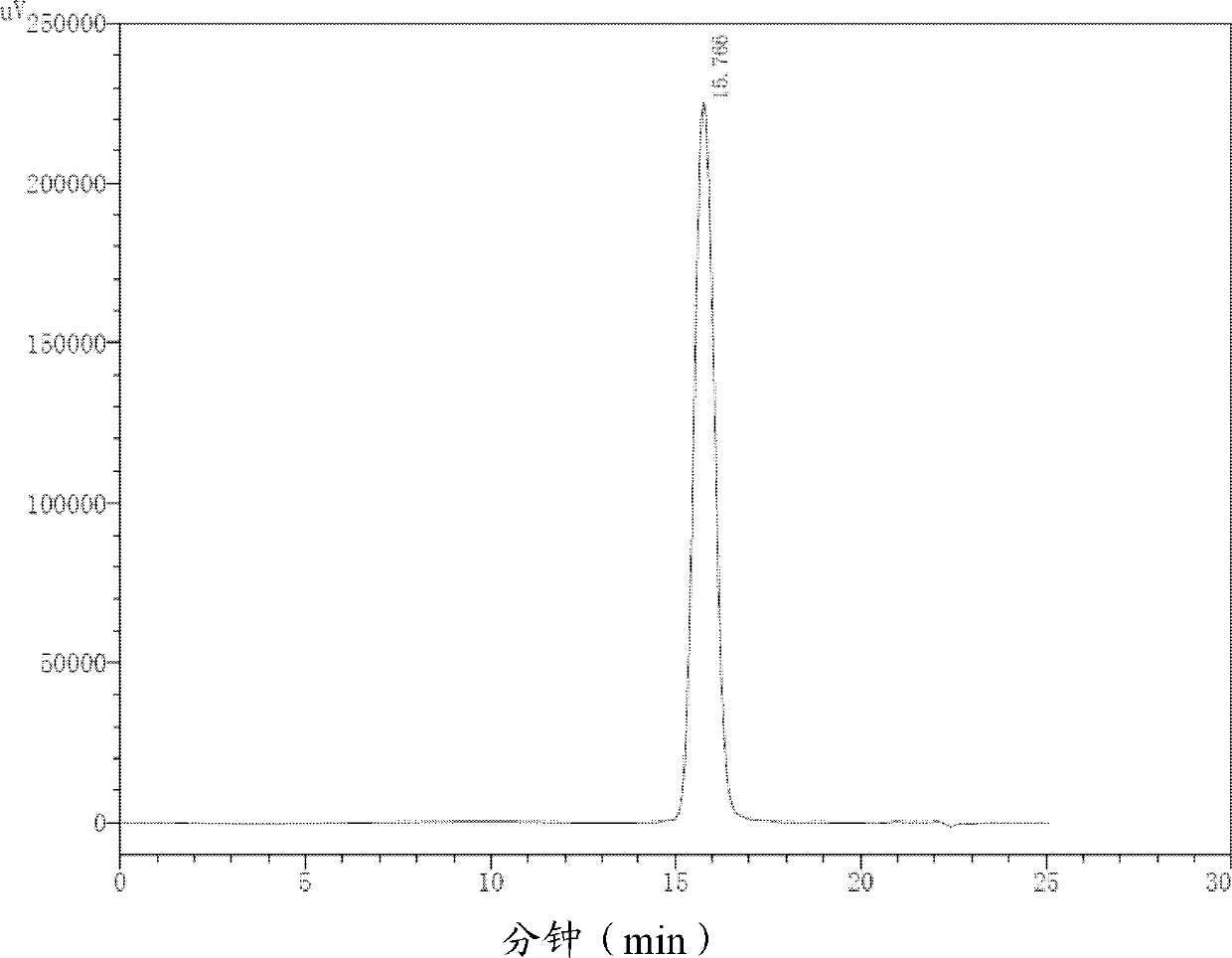

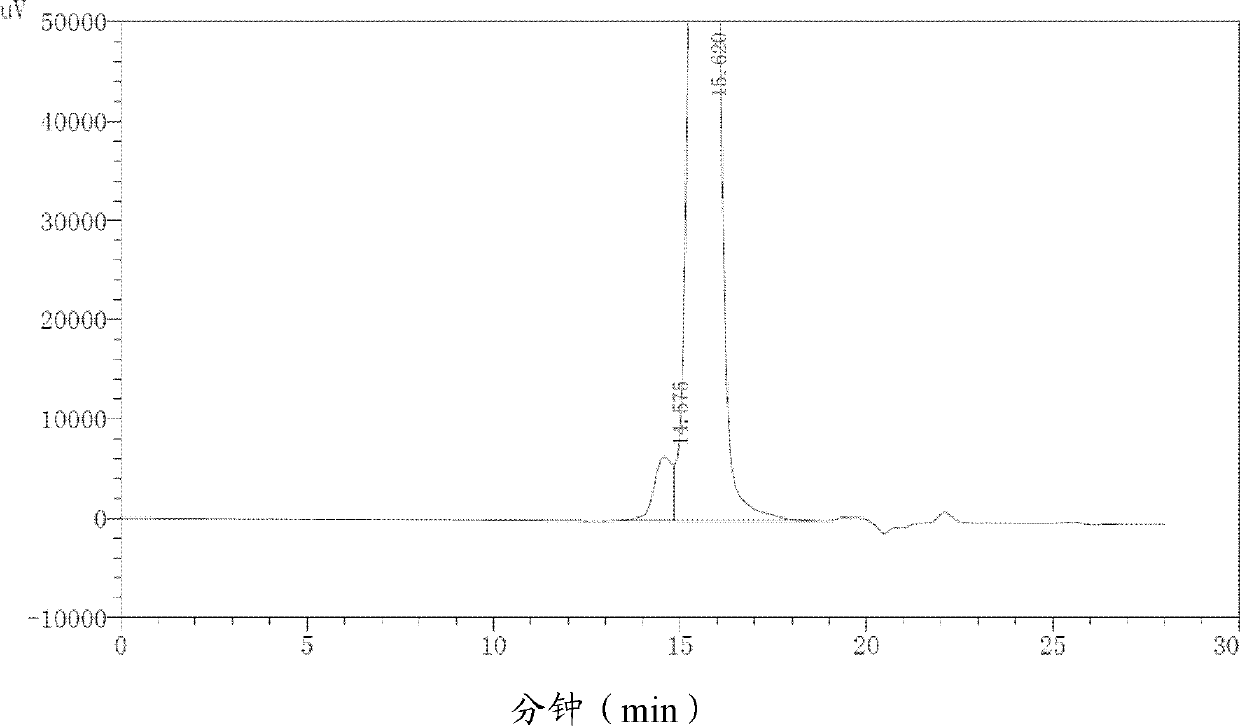

Process for preparing and separating monodisperse polyethylene glycol

InactiveUS20160075624A1Wide sourceLow costPreparation from carboxylic acid halidesEther separation/purificationPolyethylene glycol productOrganic solvent

A process for preparing and separating a monodisperse polyethylene glycol, including: dissolving a starting material of polyethylene glycol into an organic solvent for reaction with a compound represented by general formula I under catalytic action of an alkaline substance, to prepare a mixture of derivatives of polyethylene glycol having different polarities; separating the mixture of derivatives of polyethylene glycol by means of silica gel column chromatography, to obtain a monodisperse derivative of polyethylene glycol; and hydrolyzing the derivative of polyethylene glycol to obtain a monodisperse polyethylene glycol. The starting material is industrially prepared polyethylene glycol with a wide source and low cost, which provides a guarantee for popularization and application of a monodisperse polyethylene glycol product.

Owner:NANJING CARBONDE TECH +1

Protective agent for foot-and-mouth disease inactivated virus and preparation method of microcapsule vaccine

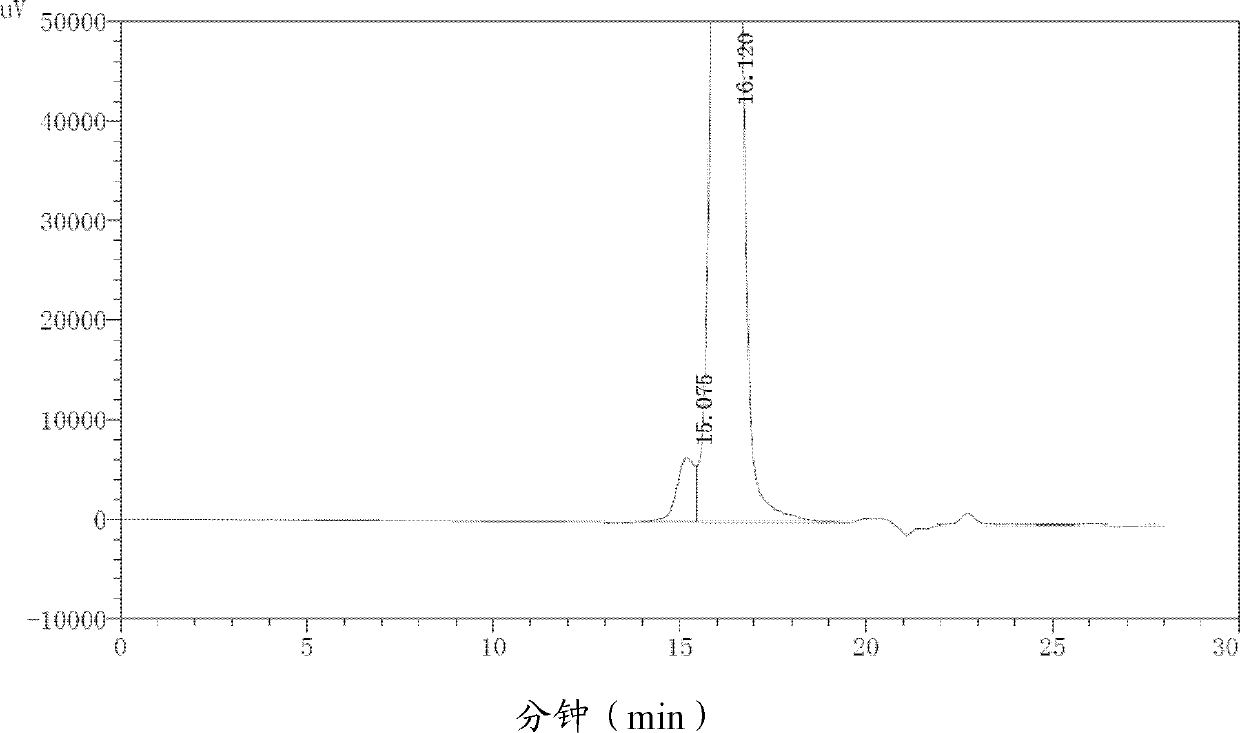

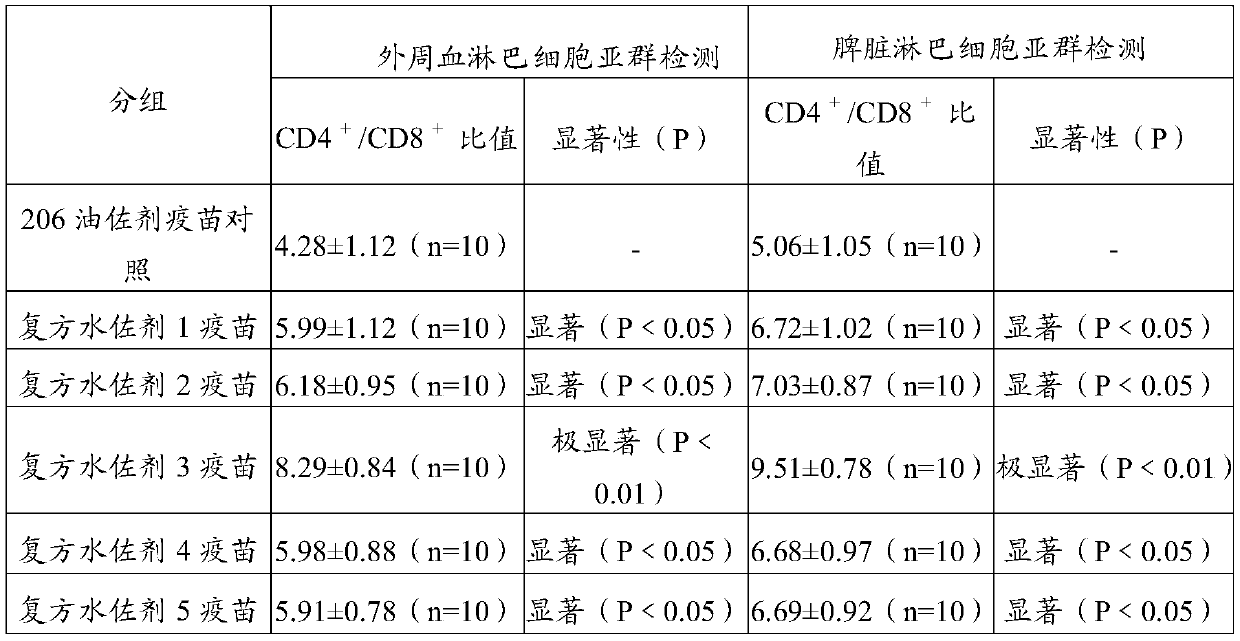

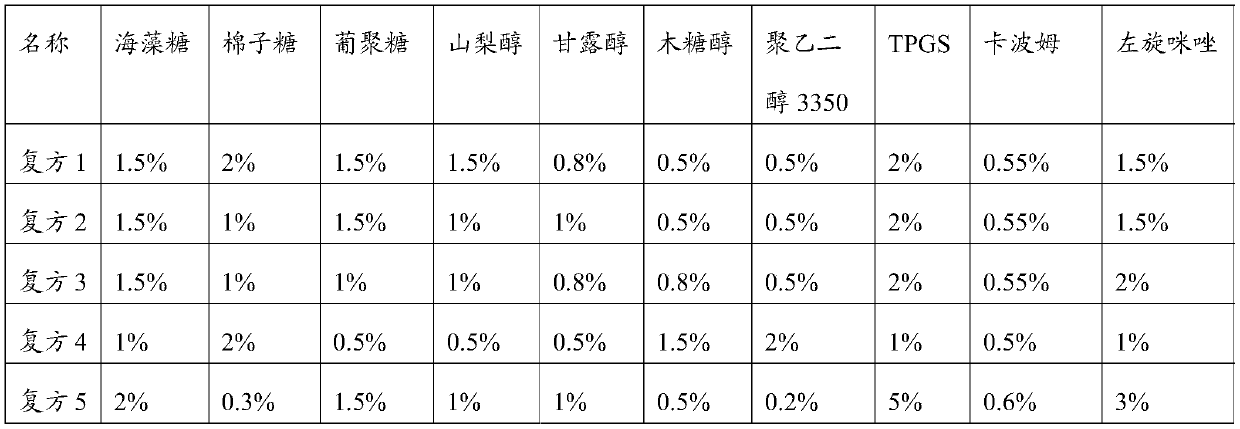

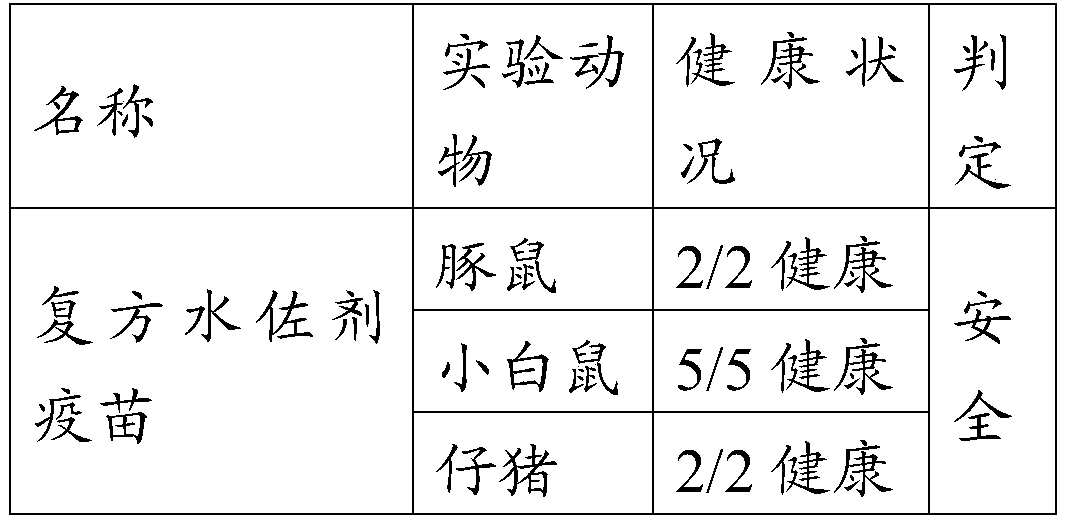

The invention provides a protective agent for a foot-and-mouth disease inactivated virus antigen. The protective agent consists of the following components: trehalose, raffinose, dextran, sorbitol, mannitol, inositol, xylitol, polyethylene glycol 3350, TPGS and propolis. The protective agent can prolong the preservation time of the antigen, protect the 146s antigen of the foot-and-mouth disease virus to be stable during production and cold chain transportation and is conducive to establishment of a foot-and-mouth disease virus antigen library and improvement of the low temperature storage stability of the 146s antigen in a foot-and-mouth disease virus antigen solution. The invention also provides a foot-and-mouth disease inactivated virus microcapsule vaccine containing the protective agent and the foot-and-mouth disease inactivated virus antigen as a core material and a preparation method thereof. The vaccine is orally taken by or injected to an animal for immunization, can produce ahigh titer FMDV antibody in 8 weeks and lasts longer than conventional oil adjuvant inactivated vaccines to achieve immune protection faster. The vaccine is directly injected for immunization withoutan adjuvant and can be inoculated to the animal by water drinking or feeding for prevention, and the clinical operation is convenient.

Owner:内蒙古必威安泰生物科技有限公司

Process for treating chlorinated organic compounds by polyethylene glycol and alkaline substances

InactiveCN102921144AAchieve dechlorination degradationAchieve complete dechlorination degradationChemical protectionPolyethylene glycol productReaction temperature

The invention discloses a process for treating chlorinated organic compounds by polyethylene glycol and alkaline substances. Wastes containing chlorinated organic pollutants are added into a reactor, the polyethylene glycol and the alkaline substances are sequentially added into the reactor, and dechlorination degradation reaction can be achieved. The process has the advantages that the reaction time is short, the reaction temperature is low and the reaction materials are easy to obtain.

Owner:TSINGHUA UNIV

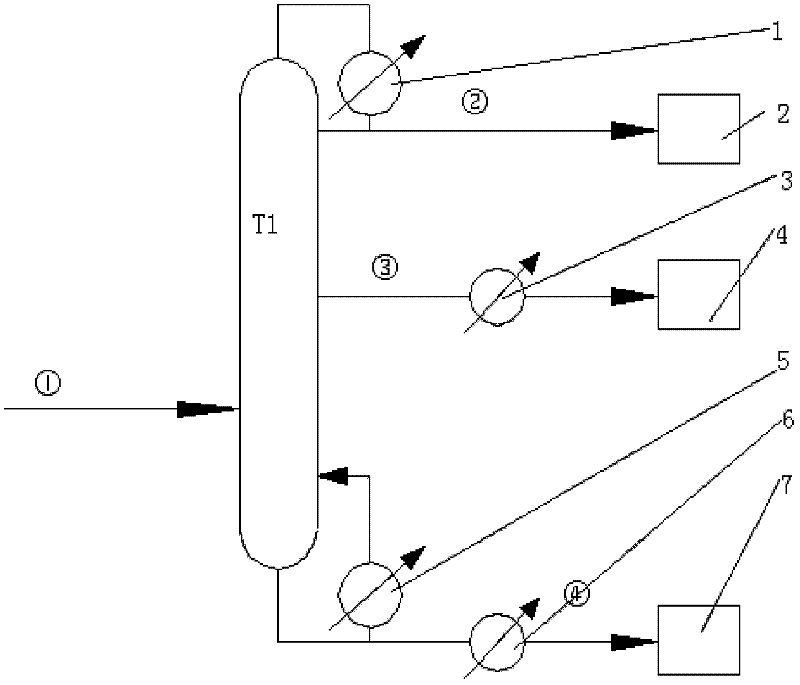

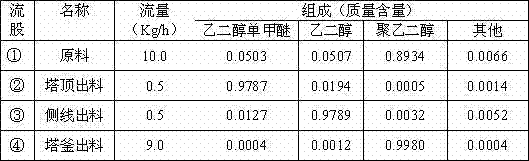

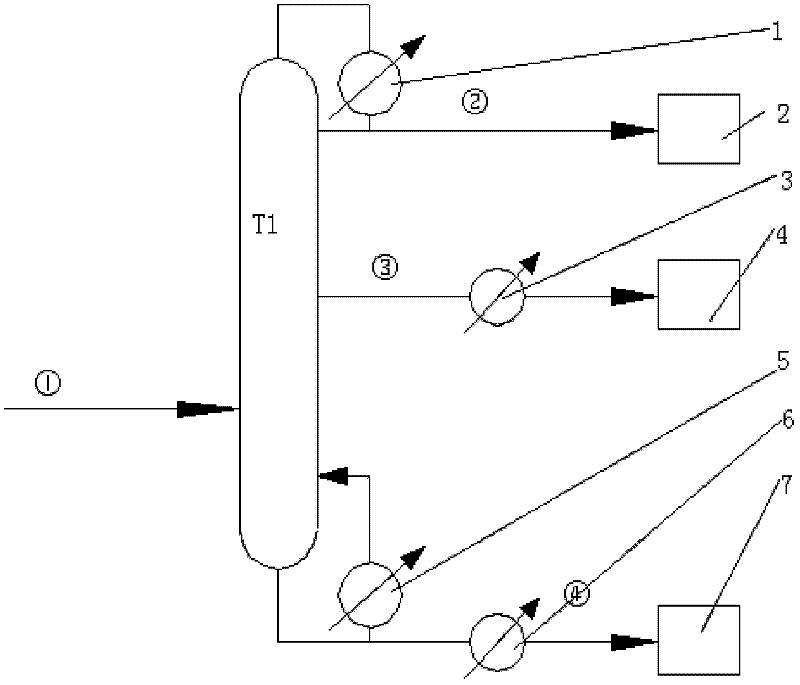

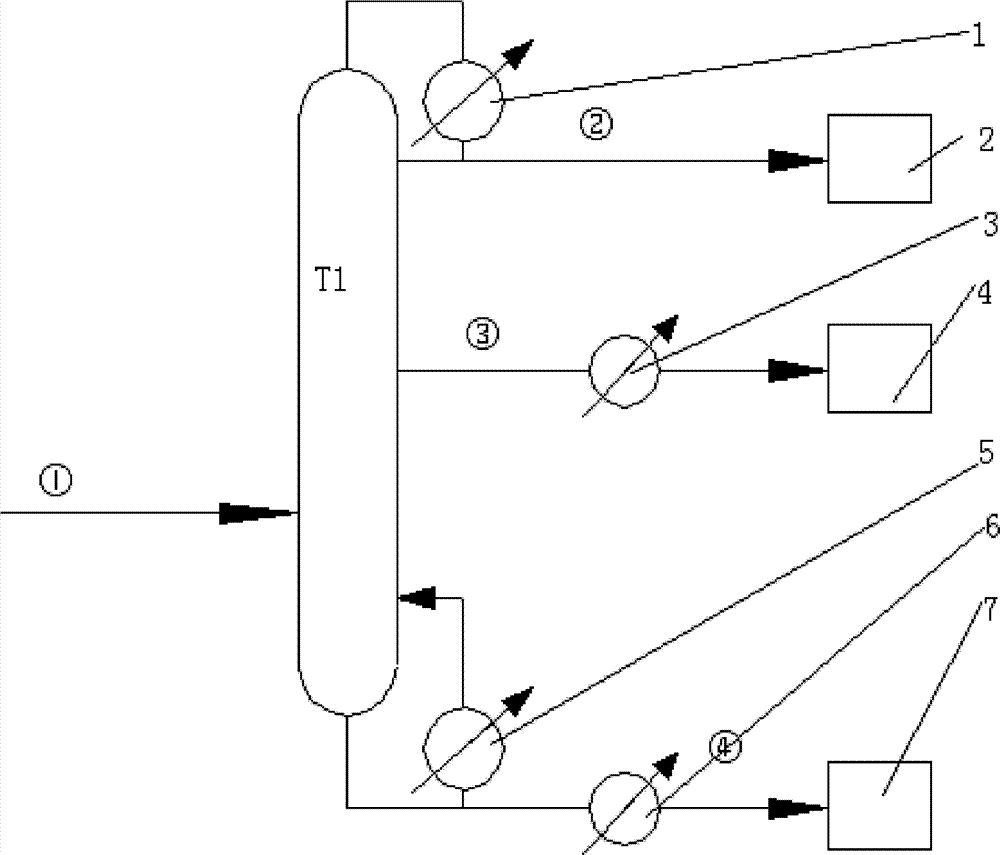

Lateral line rectification separation method for organic components of polyethylene glycol, ethylene glycol and ethylene glycol monomethyl ether in crystalline silicon cutting mixing recovery liquid

ActiveCN102643173AOptimizing Process ParametersSave costsEther separation/purificationOrganic compound preparationPolyethylene glycol productPolymer science

The invention provides a lateral line rectification separation method for organic components of polyethylene glycol, ethylene glycol and ethylene glycol monomethyl ether in crystalline silicon cutting mixing recovery liquid, which comprises the following steps of: (1) taking moisture-free crystalline silicon cutting mixing recovery liquid as raw material, and pumping into a lateral line fractionating tower; (2) carrying out fraction at 124-125 DEG C in a cutting way on the top of the tower, controlling reflux ratio, and recovering an ethylene glycol monomethyl ether product from the top of the tower to enter into an ethylene glycol monomethyl ether storing tank; (3) carrying out fraction at 195-200 DEG C in a cutting way at the lateral line on the upper part of the tower, exchanging heat by a heat exchanger to be taken as an ethylene glycol product to enter into a storing tank; and (4) reheating material on a tower kettle by a reboiler, controlling the temperature to be in a range of 240 DEG C to 245 DEG C, cooling some material to be taken as a polyethylene glycol product to enter into a polyethylene glycol product storing tank. The method adopts optimized technology parameters, and adopts the lateral line of a single tower to separate three components in the crystalline silicon cutting mixing recovery liquid in a rectifying way. The ethylene glycol monomethyl ether is recovered from the top of the tower, the ethylene glycol is recovered from the lateral line, and the polyethylene glycol is obtained from the tower kettle. Due to single-tower operation, the equipment cost and the energy consumption can be reduced compared with those of the conventional method.

Owner:JIANGSU YINGTIAN CHEM

Polyethylene glycol saturated substrate and method of making

InactiveUS7264638B2Improve loftImprove handsSucessive textile treatmentsOther chemical processesPolyethylene glycol productPolymer science

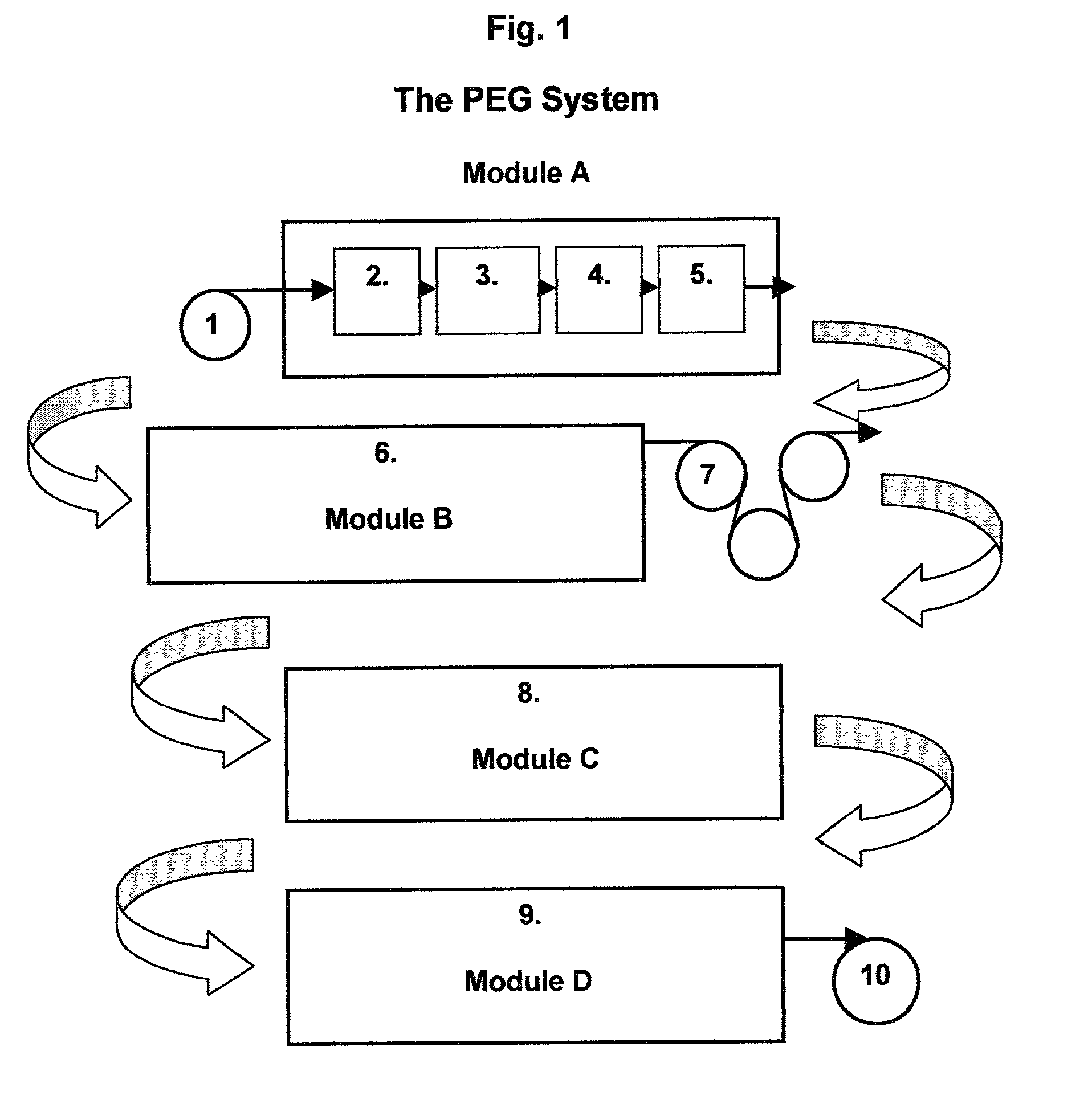

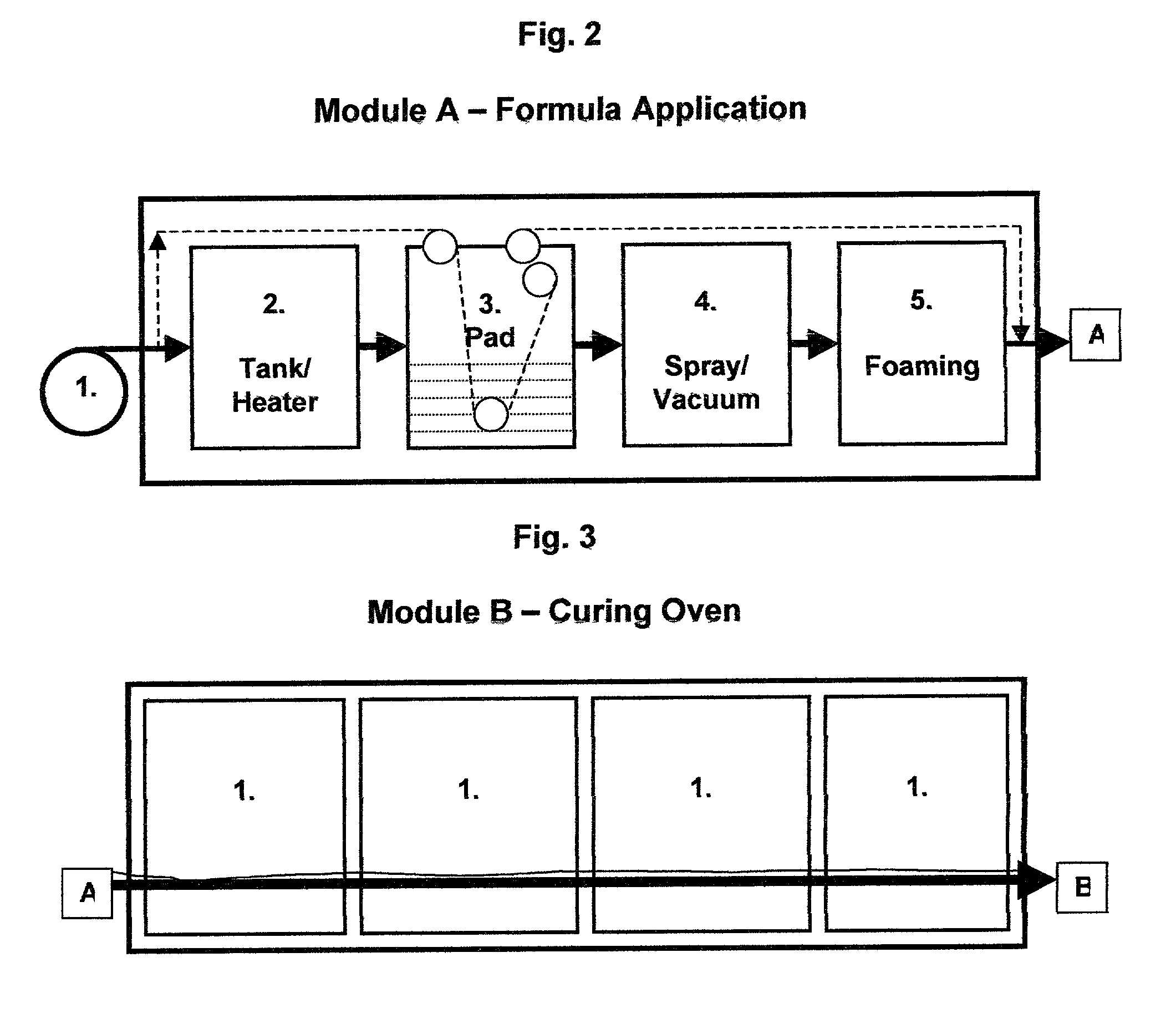

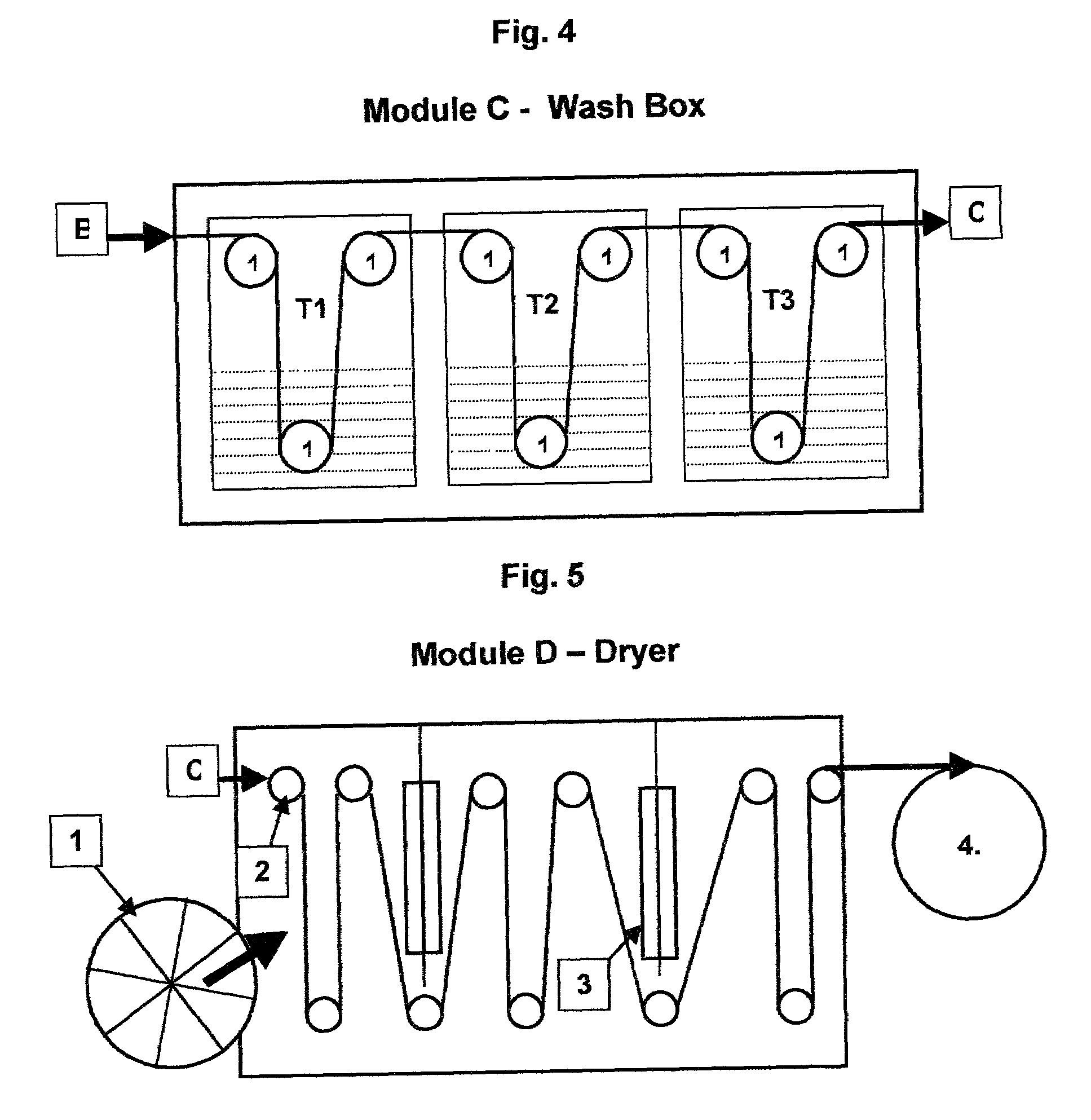

Polyethylene glycol may be applied and bound to a broad range of substrates and materials, such as nonwoven, woven, knit, foam and film structures resulting in the manufacture of varied and useful commercial products. The invention describes various techniques and methods for saturating and bonding polyethylene glycol to a wide range of types of materials and substrates in a continuous commercial production environment.Rather than using numerous machines and processes scattered around a production environment, or even located in multiple locations, which is inefficient, results in poor quality products, generates unacceptable scrap and waste and is not cost effective, the invention describes various methods and techniques used to permanently apply polyethylene glycol to various types of substrate and materials in an integrated production environment. Also disclosed are some of the numerous features and benefits added to substrates and materials to which polyethylene glycol has been permanently bonded.

Owner:ARTLEY JOHN WILLIAM +1

A method for preparing homogeneous-distribution polyethylene glycol by utilizing a microchannel reactor

A method for preparing homogeneous-distribution polyethylene glycol by utilizing a microchannel reactor is disclosed. The method includes (1) a step of preparing a catalytic system, namely a step of subjecting polyol as an initiator and an alkali metal catalyst as a raw material to ultrasonic vibration dissolving; (2) a step of raw material premixing, namely a step of feeding the catalytic systemand epoxy ethane into a premixer at the same time, and premixing the materials at 0-10 DEG C under 0.5-1.0 MPa for 50-500 ms; (3) a micro reaction step, namely a step of subjecting the premixed raw materials to continuous polymerization through the microchannel reactor to obtain a reaction solution, with the reaction temperature being controlled to be 100-200 DEG C, residence time being 2 to 20 min, the reaction pressure being 1.0 to 4.5 MPa; and (4) a step of aftertreatment, namely a step of adding purified water for dissolution at 50-80 DEG C, allowing the solution to pass through an ion exchange resin column, performing filtration and then vacuum dehydration, and cooling a product to room temperature to obtain a polyethylene glycol product. The reaction efficiency is greatly improved, which is very favorable for reducing the price of the homogeneous-distribution polyethylene glycol. The microchannel reactor has no scale effect and is very suitable for industrial scale production.

Owner:南京威尔药业科技有限公司

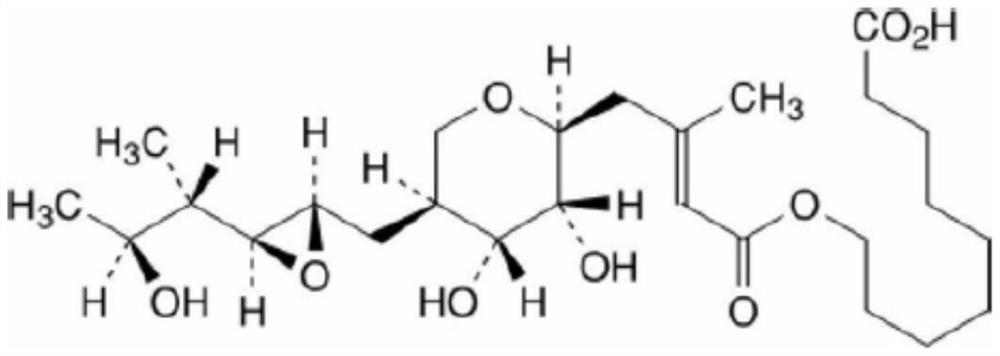

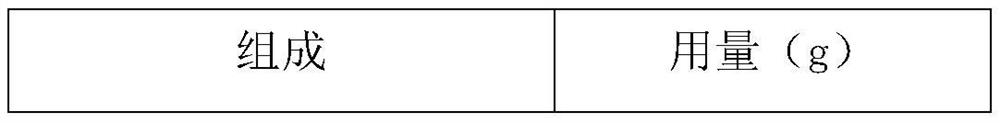

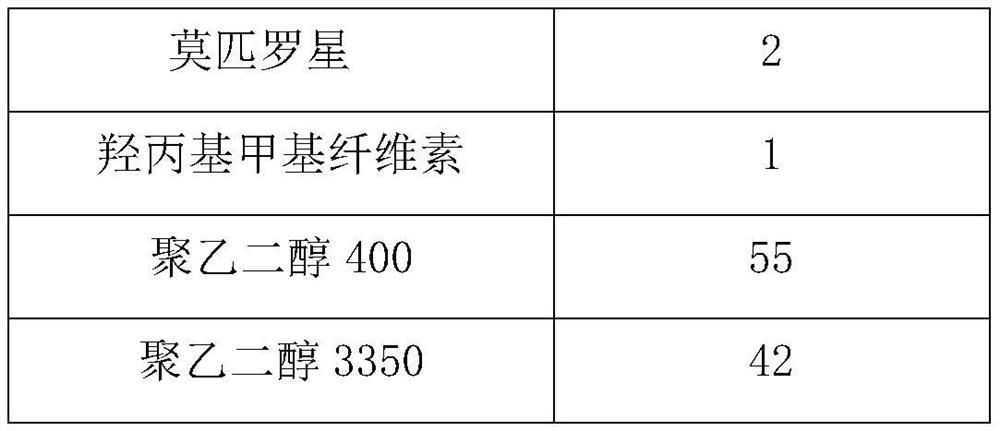

Preparation method for mupirocin ointment

InactiveCN105412000ASmall granularityEnsure delicateAntibacterial agentsOrganic active ingredientsPolyethylene glycol productPEG 400

The invention discloses a preparation method for a mupirocin ointment. The mupirocin ointment is prepared from, by mass, 1-5 parts of a main drug mupirocin, 19-80 parts of polyethylene glycol 3350 and 19-80 parts of polyethylene glycol 400. The preparation method comprises the steps that the polyethylene glycol 3350 is dissolved at 80 DEG C until the solution is clear to obtain a polyethylene glycol 3350 solution; the main drug mupirocin is dispersed with the polyethylene glycol 400, the mixture is added into the polyethylene glycol 3350 solution, 80-DEG C heat preservation is performed for 30 min, low-speed stirring is performed, it is guaranteed that the main drug mupirocin is completely dissolved, and materials are obtained; cooling water is started, high-speed stirring is started at the speed of 600 r / min for 30 min in the cooling process until the materials are cooled to 55 DEG C, then a high-speed emulsification head is started, a 3000-r / min high-speed shearing state is kept until the materials are cooled to 38 DEG C, and the material is discharged and filled. According to the preparation method, the particle size of 95% of the prepared materials is smaller than 50 micrometers, and the problem that filling amount cannot be controlled in the filling process is solved.

Owner:FRONT PHARM PLC

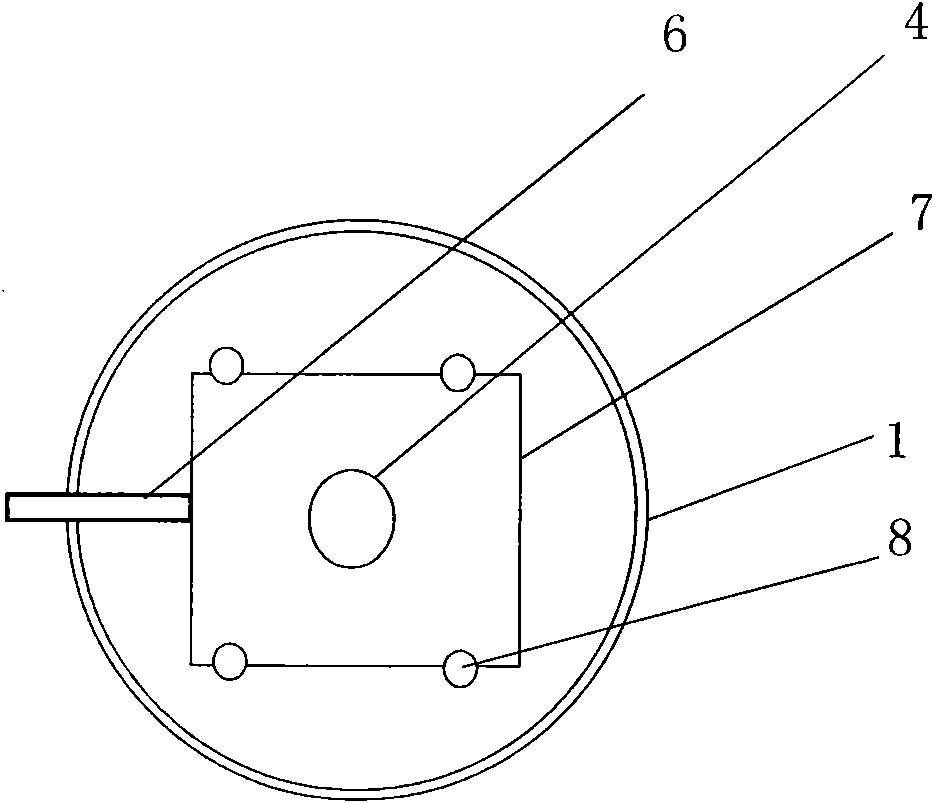

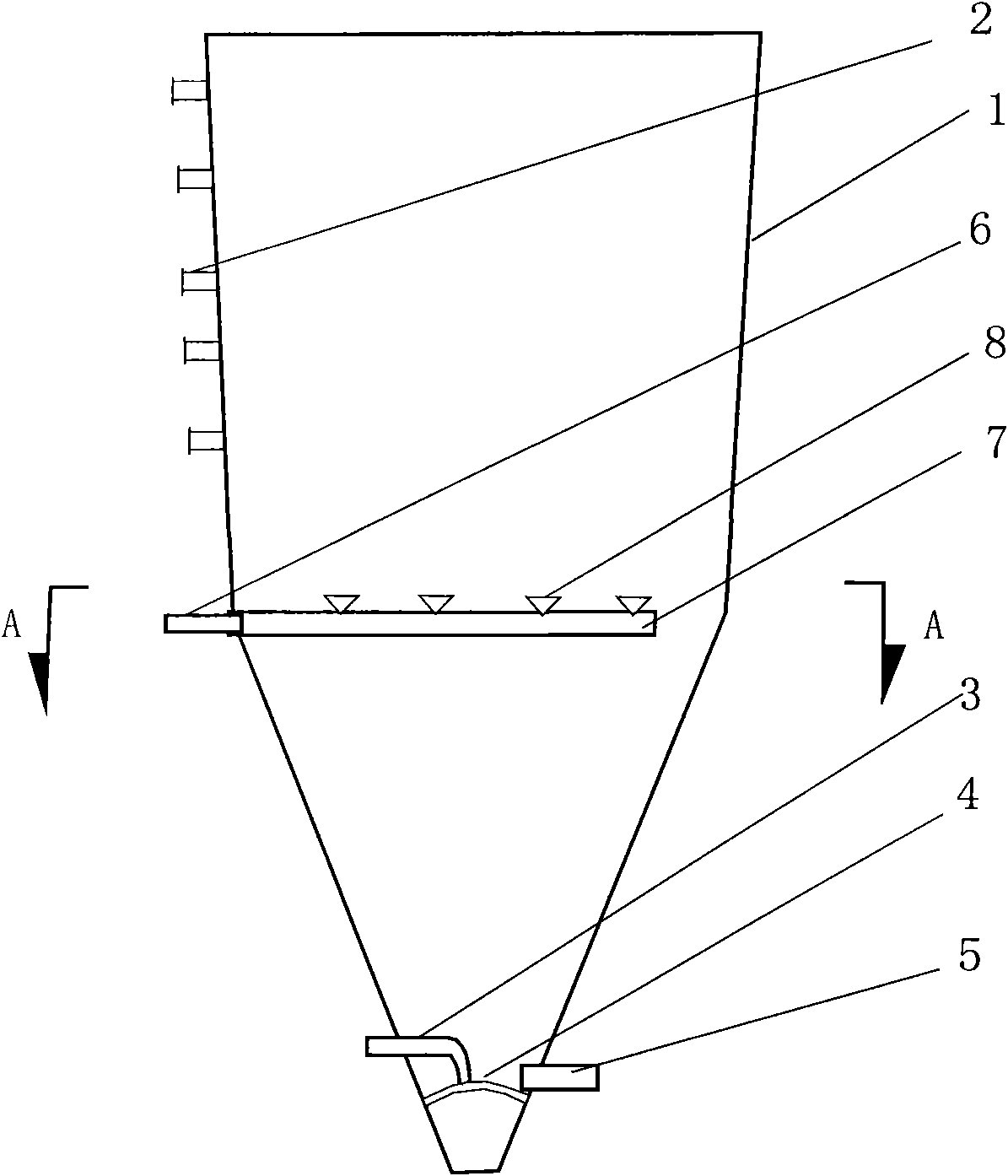

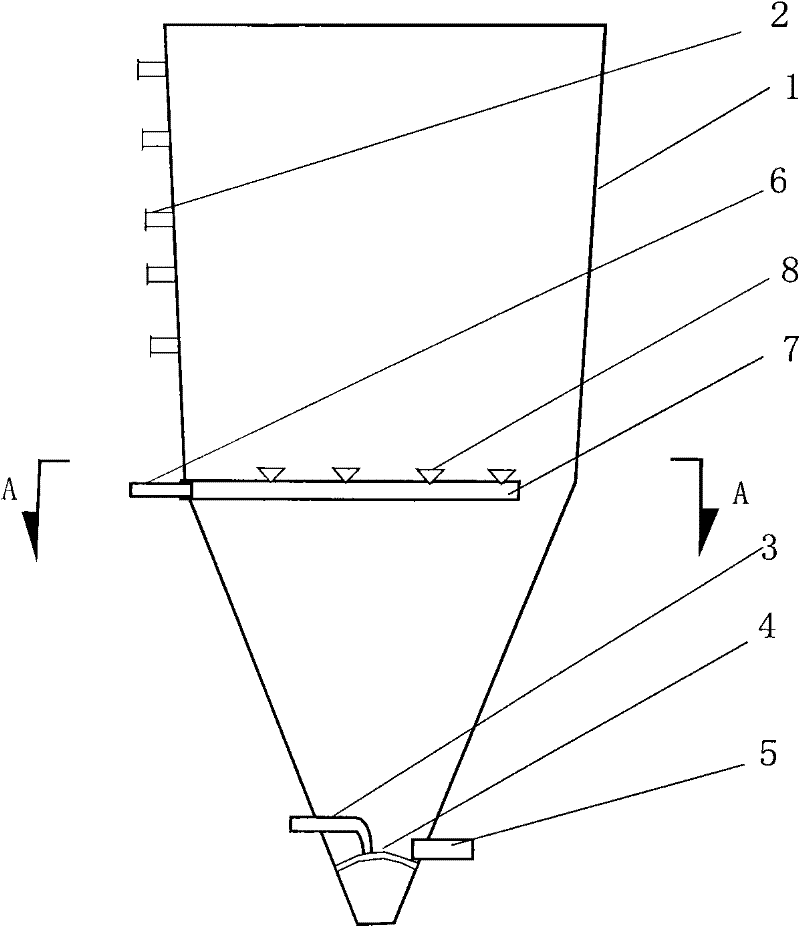

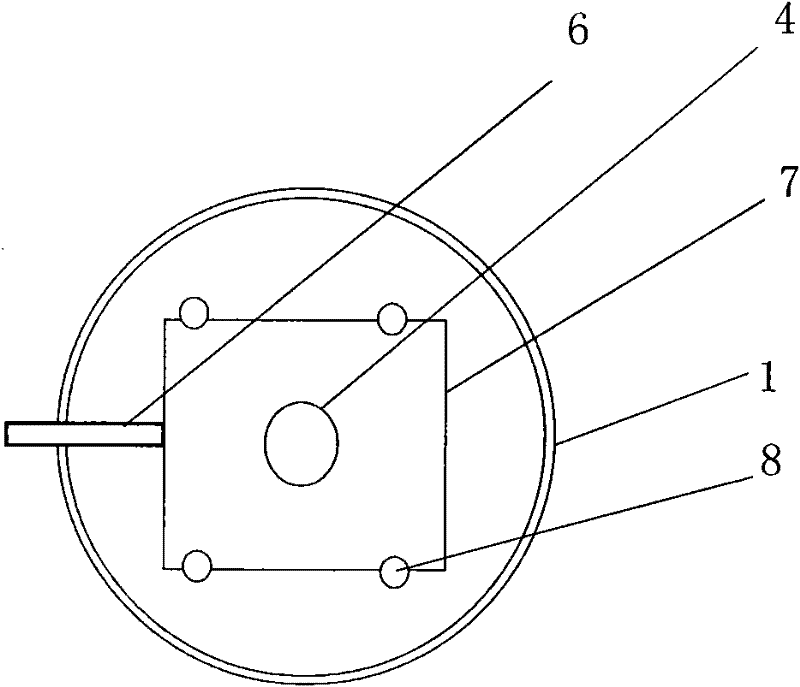

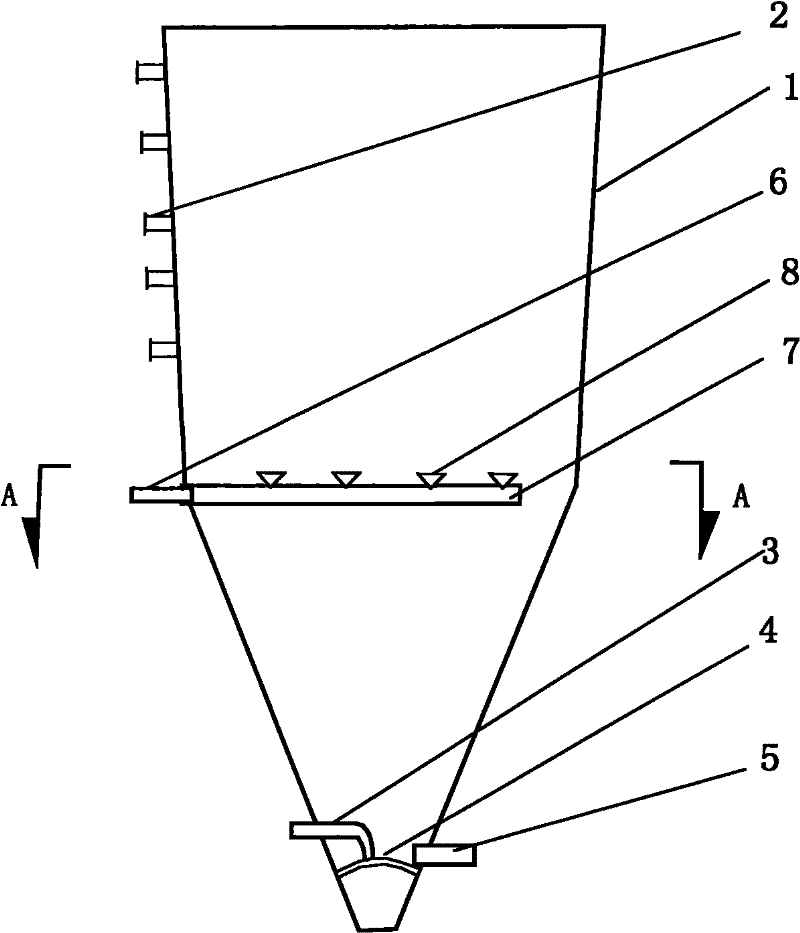

Waste silicon wafer-cutting fluid processing method and silicon carbide rinsing device

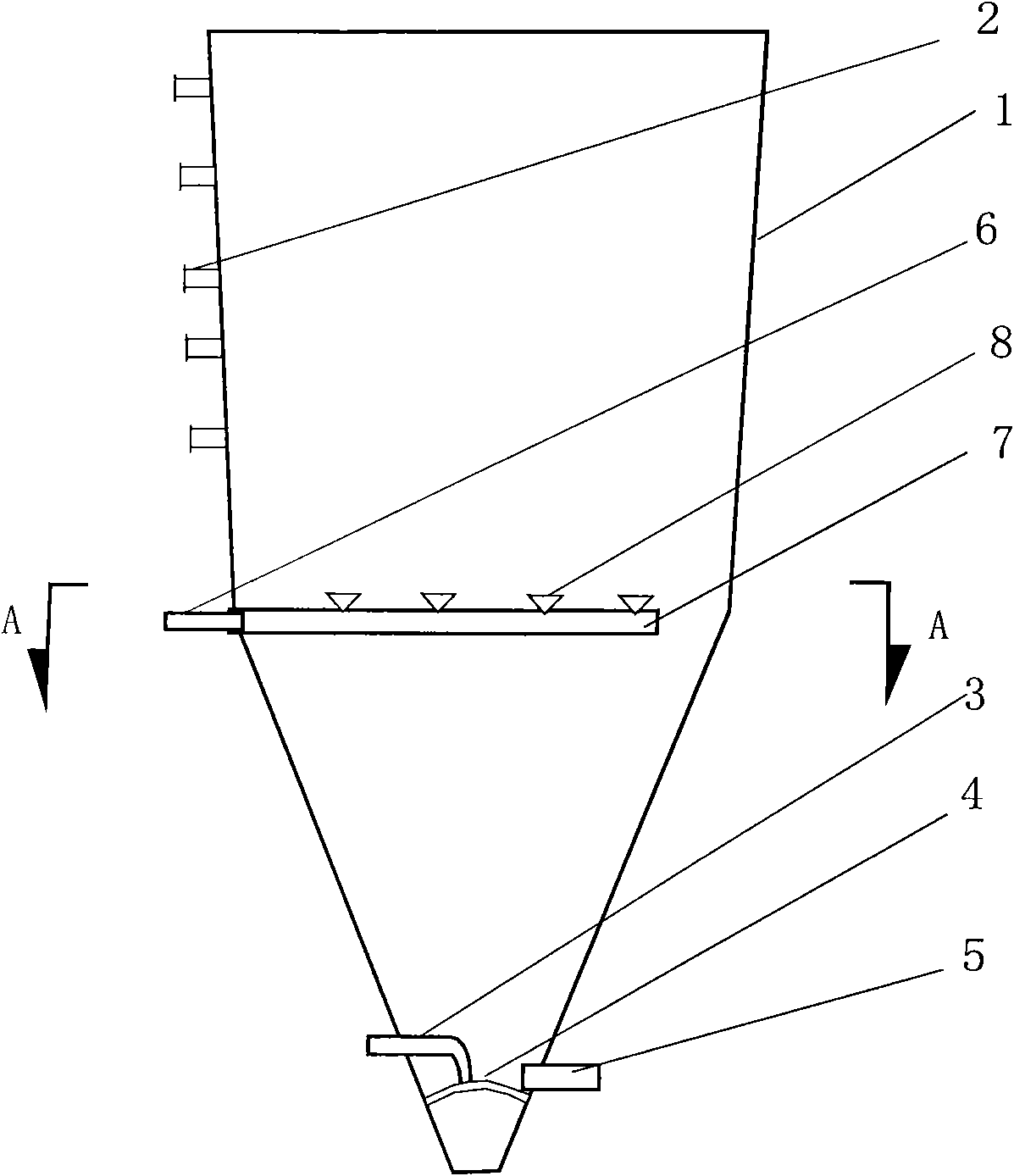

The invention discloses a waste silicon wafer-cutting fluid processing method and a silicon carbide rinsing device. The processing method includes the following steps that: (A) water is added to dilute waste silicon wafer-cutting fluid and mixed, and a magnet is used for attracting iron; (B) flocculant is added, and solid and liquid are separated; (C) water is added to dilute the solid, and the silicon carbide suspension is added with sodium hydroxide, heated for reaction, washed by water, added with acid and washed until the pH value reaches 6.5 to 7, so that a crude silicon carbide product is obtained; (D) the crude product is separated, and after drying, a finished silicon carbide product is obtained; (E) the liquid is filtered, and after dehydration, a finished polyethylene glycol product is obtained. The scheme increases the purity of the sodium carbide, and reduces the consumption of acid and alkaline. The silicon carbide rinsing device comprises a rinsing bucket, the sidewall of the rinsing bucket is provided with a plurality of decanting outlets, the end of the rinsing bucket is provided with a water inlet tube, and a water distributor is arranged in the cone; the wall of the rinsing bucket is also provided with an air inlet, and an air tube is arranged in the bucket, and is provided with a plurality of microporous air distributors. The device can prevent the sediment of silicon carbide, thus enhancing the rinsing effect.

Owner:ZHEJIANG YUANSHENG SILICON MATERIALS

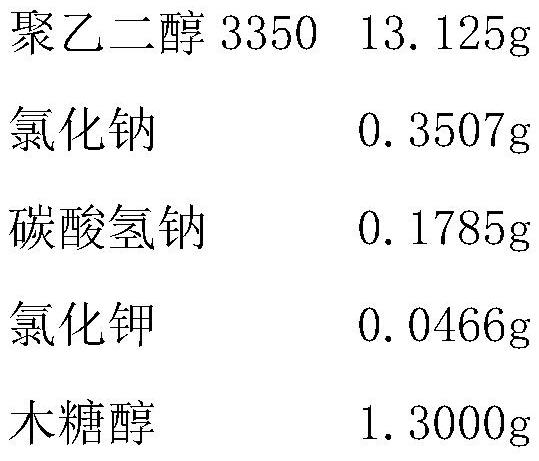

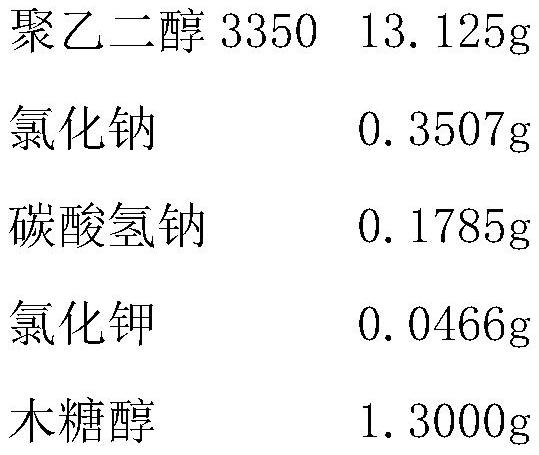

Preparation of polyethylene glycol sodium potassium oral pharmaceutical preparation

InactiveCN112494511AFast dissolutionReduce dosagePowder deliveryDigestive systemSodium bicarbonatePolyethylene glycol product

The invention relates to a preparation method of a polyethylene glycol sodium potassium oral pharmaceutical preparation. The method comprises the following steps of (1) weighing sodium bicarbonate, sodium chloride, potassium chloride, xylitol and polyethylene glycol 3350, putting the components into a stirrer, spraying a proper amount of absolute ethyl alcohol in stirring for wetting, performing continuous stirring for 30 minutes after wetting, and taking out a mixture; (2) performing full drying, grinding and crushing dried coarse powder, and sieving the grounded and crushed powder with an 80-mesh sieve to obtain powder; and (3) performing sub-packaging to obtain the polyethylene glycol sodium potassium oral pharmaceutical preparation.

Owner:TIANJIN PRECEDE MEDICAL TRADE

Toothpaste composition and method of applying a single serving of toothpaste to a toothbrush

A toothpaste composition includes different combinations of konjac gum and / or agar-agar, alginates, gelatin, pectin, xanthan, tara gum, gum arabic, carrageenan, celluloses, gellan gum, guar gum, inulin, konjac, locust bean gum, pectin, tragacanth, xanthan, polyethylene glycol-3350, xylitol, calcium carbonate, stevia, quillaja, liquid bioflavonoid extract, and water. The toothpaste composition produces a toothpaste product that maintains its shape prior to being used for brushing one's teeth and is preferably formed into a single serving of toothpaste stored in an open-top compartment having a removable protective film. A method of applying a single serving of toothpaste to a toothbrush includes the steps of pressing the bristles of a toothbrush against the single serving of toothpaste so that the single serving of toothpaste clings or otherwise adheres to the bristles, and subsequently pulling the toothbrush away from the compartment for brushing one's teeth.

Owner:SCHAPIRO EDWARD +4

Mupirocin ointment and preparation method thereof

PendingCN114053210AImprove thinningImprove the problem of excellent demulsificationAntibacterial agentsOrganic active ingredientsPolymer sciencePolythylene glycol

Owner:HAINAN JINXING PHARMA

Mupirocin ointment and preparation method thereof

InactiveCN110787128AImprove stabilityImprove thin problemAntibacterial agentsOrganic active ingredientsPolymer sciencePolythylene glycol

The invention discloses a mupirocin ointment. The ointment is prepared from the following raw materials in parts by weight: 20 to 100 parts of mupirocin, 500 to 700 parts of polyethylene glycol 3350,400 to 600 parts of polyethylene glycol 400, 1 to 2 parts of vitamin E and 39 to 58 parts of propylene glycol. The invention also discloses a preparation method of the mupirocin ointment. The method comprises the following steps: taking the polyethylene glycol 400, adding the polyethylene glycol 3350 and the propylene glycol, and performing uniform mixing to obtain a solution A; taking the polyethylene glycol 400, adding the mupirocin and the vitamin E, and performing uniform mixing to obtain a suspension B; and uniformly mixing the solution A and the suspension B at 55-65 DEG C, cooling obtained mixture to 35-45 DEG C, performing grinding, cooling ground material to room temperature, and performing canning to obtain the ointment. The ointment has uniformly-distributed active ingredients,has proper consistency, is easy to smear, and is convenient for patients to use.

Owner:FRONT PHARM PLC

Method for recovering polyethylene glycol and silicon carbide from silicon crystal cutting waste liquid

The invention discloses a method for recovering polyethylene glycol and silicon carbide from silicon crystal cutting waste liquid. The method comprises the following steps of: A) diluting the cutting waste liquid with water and stirring, extracting metal scarp iron from the mixture by using a magnet after ultrasonic processing; B) adding a flocculating agent into the mixture for centrifugal separation; C) diluting solid I with water, adding sodium hydroxide into the solution, heating the mixture to perform reaction, cleaning the mixture with the water, adding an acid into the mixture, and cleaning the mixture with the water to obtain a crude silicon carbide product; D) performing centrifugal separation on the crude silicon carbide product, and drying the crude product to obtain a finishedsilicon carbide product; and E) filtering the liquid, heating, evaporating and dehydrating the filtered liquid to obtain a finished polyethylene glycol product. In the scheme, the mixture is diluted first, so the recovery rate of the polyethylene glycol is improved. The silicon and iron content of the crude silicon carbide product and the consumption level of the acid and alkali are reduced by ultrasonic processing and iron removal. The method has the characteristics of reasonable process, environmental protection and the like.

Owner:ZHEJIANG YUANSHENG SILICON MATERIALS

Mupirocin ointment preparation

PendingCN113520994APH dependentImprove stabilityAntibacterial agentsOrganic active ingredientsPolyethylene glycol productPolymer science

Owner:FRONT PHARM PLC

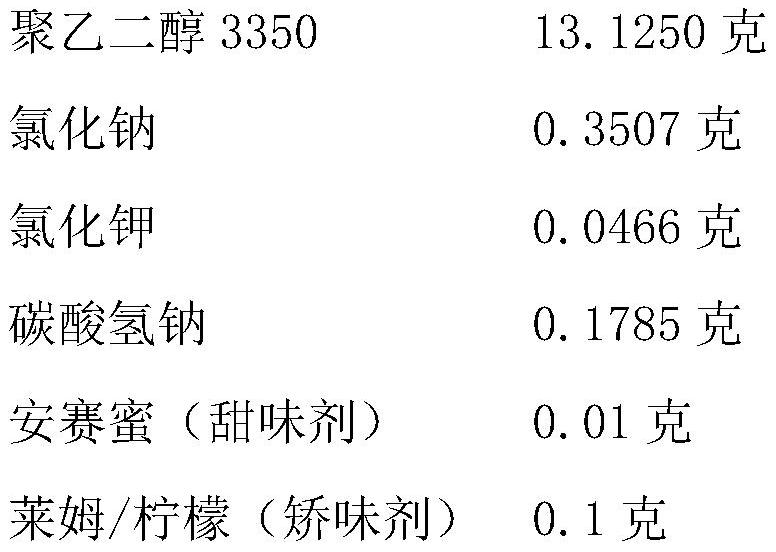

Polyethylene glycol sodium potassium powder and preparation method thereof

ActiveCN114432339AWell mixedImprove liquidityPowder deliveryDigestive systemSodium bicarbonatePolyethylene glycol product

The invention relates to the technical field of medical biology, in particular to a preparation method of polyethylene glycol sodium potassium powder. Comprising the following steps: preparing a solution I: adding polyethylene glycol 3350 into a hot melting pot, and carrying out hot melting to obtain the solution I; preparing a solution II: taking sodium chloride, potassium chloride, sodium bicarbonate and a sweetening agent, adding 3 times of purified water, stirring, dissolving and clarifying to obtain the solution II; preparing a solution III: adding the solution II into the solution I, stirring and heating to obtain a mixed solution III; spray drying: starting a fan of a spray drying tower, feeding natural air, spraying the solution III into the spray tower, starting the fan of the spray drying tower for heating after spraying is completed, and stopping the spray drying tower for discharging; sieving: adding the spray-dried material into a shaking sieve; total mixing: adding a flavoring agent into the sieved material, and mixing to obtain a total mixture of the polyethylene glycol sodium potassium powder. The invention aims to solve the problems that the polyethylene glycol sodium-potassium powder prepared by the existing method is poor in uniformity and poor in total mixture flowability, and the curative effect is influenced.

Owner:重庆希尔安药业有限公司

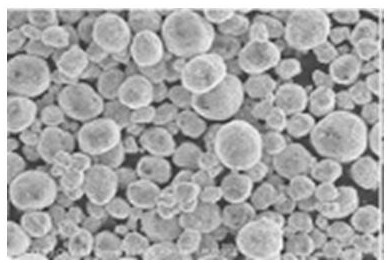

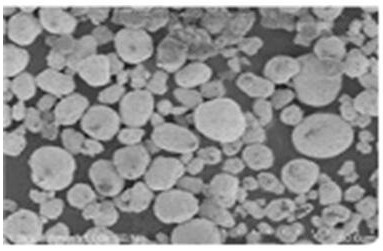

Functional giant clam powder toothpaste

InactiveCN107049914ASignificant swellingVisibly brightensCosmetic preparationsToilet preparationsAdditive ingredientToothpaste

The invention relates to functional giant clam powder toothpaste which comprises the following components in parts by weight: 15-40 parts of giant clam powder, 20-40 parts of glycerinum, 20-40 parts of 70% sorbitol, 0.3-0.6 part of carboxymethylcellulose, 1-10 parts of polyethylene glycol 3350 and 1-3 parts of lauryl sodium sulfate, wherein the giant clam powder is screened with a 200-500-mesh sieve. Tasty, refreshing and cooling mint essential oil, sodium benzoate, saccharin sodium salt and beautiful pigment are further added into the toothpaste. According to the invention, the giant clam powder containing a large amount of calcium carbonate, various amino acids and microelements is used as a friction agent in the toothpaste; the toothpaste has obvious effects of eliminating swelling, whitening, nourishing, resisting aging and preventing osteoporosis, is simple in ingredient, is green and natural and is conveniently prepared; a new variety is supplied for the toothpaste market; and the functional giant clam powder toothpaste has wide market values.

Owner:GENOBIO PHARM CO LTD

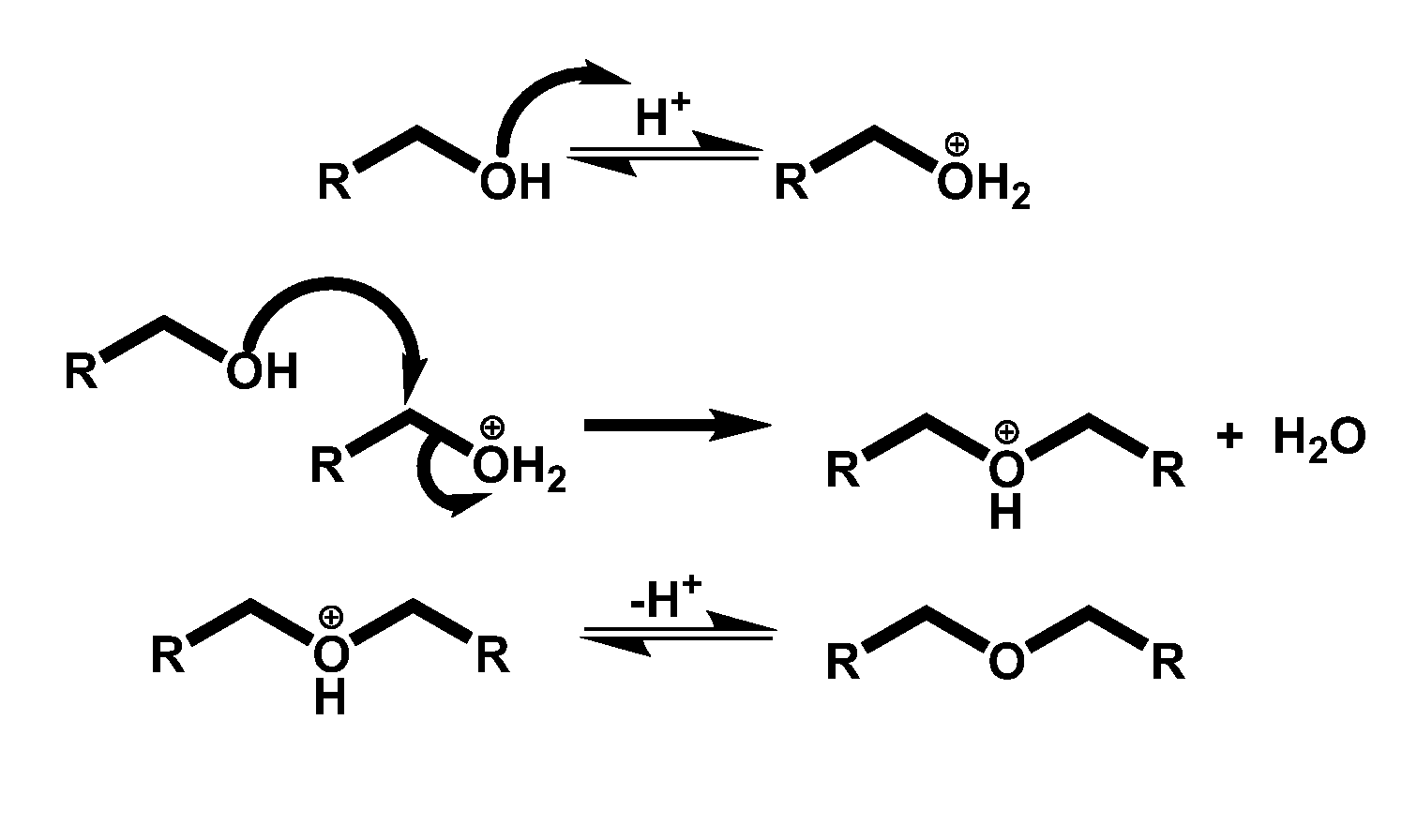

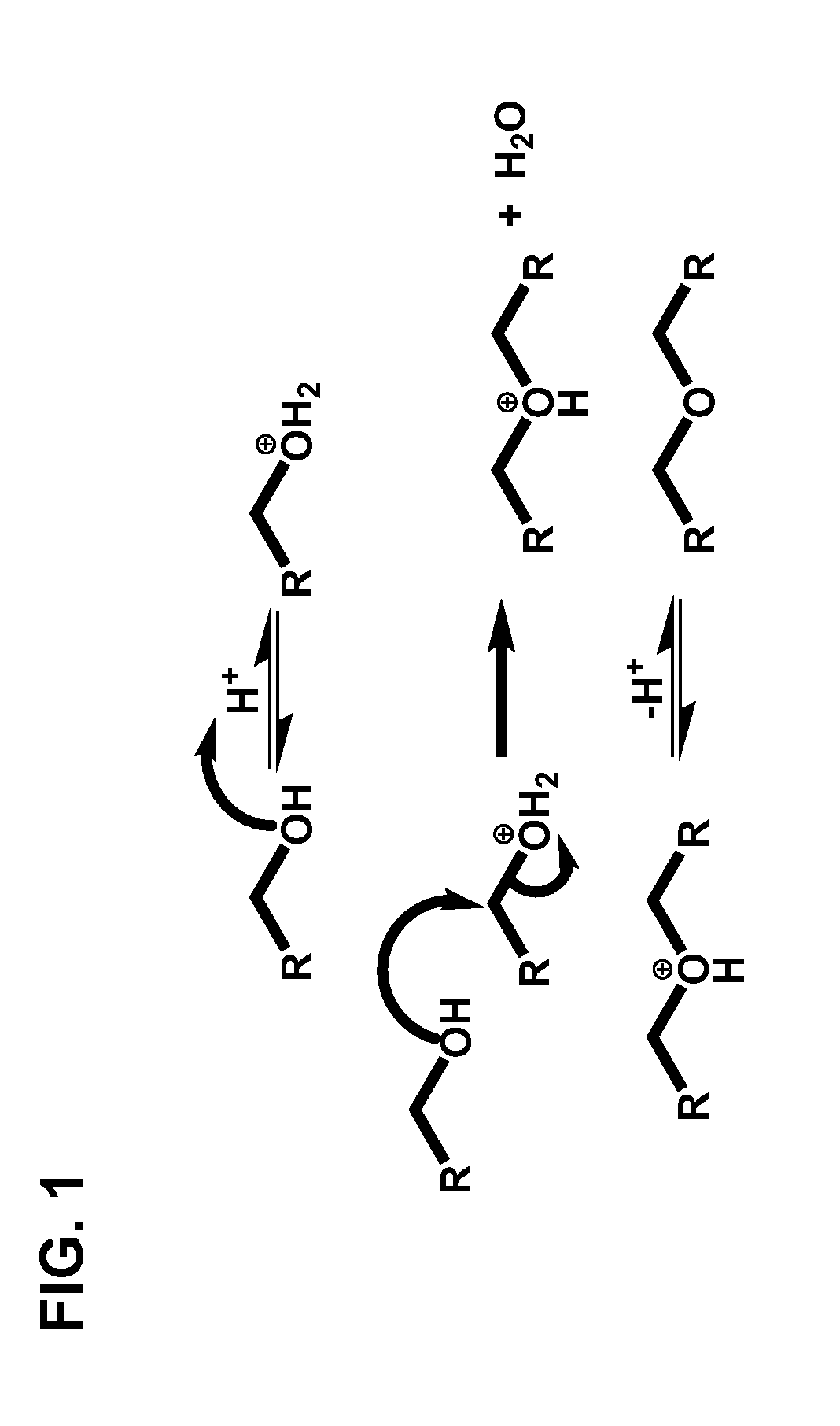

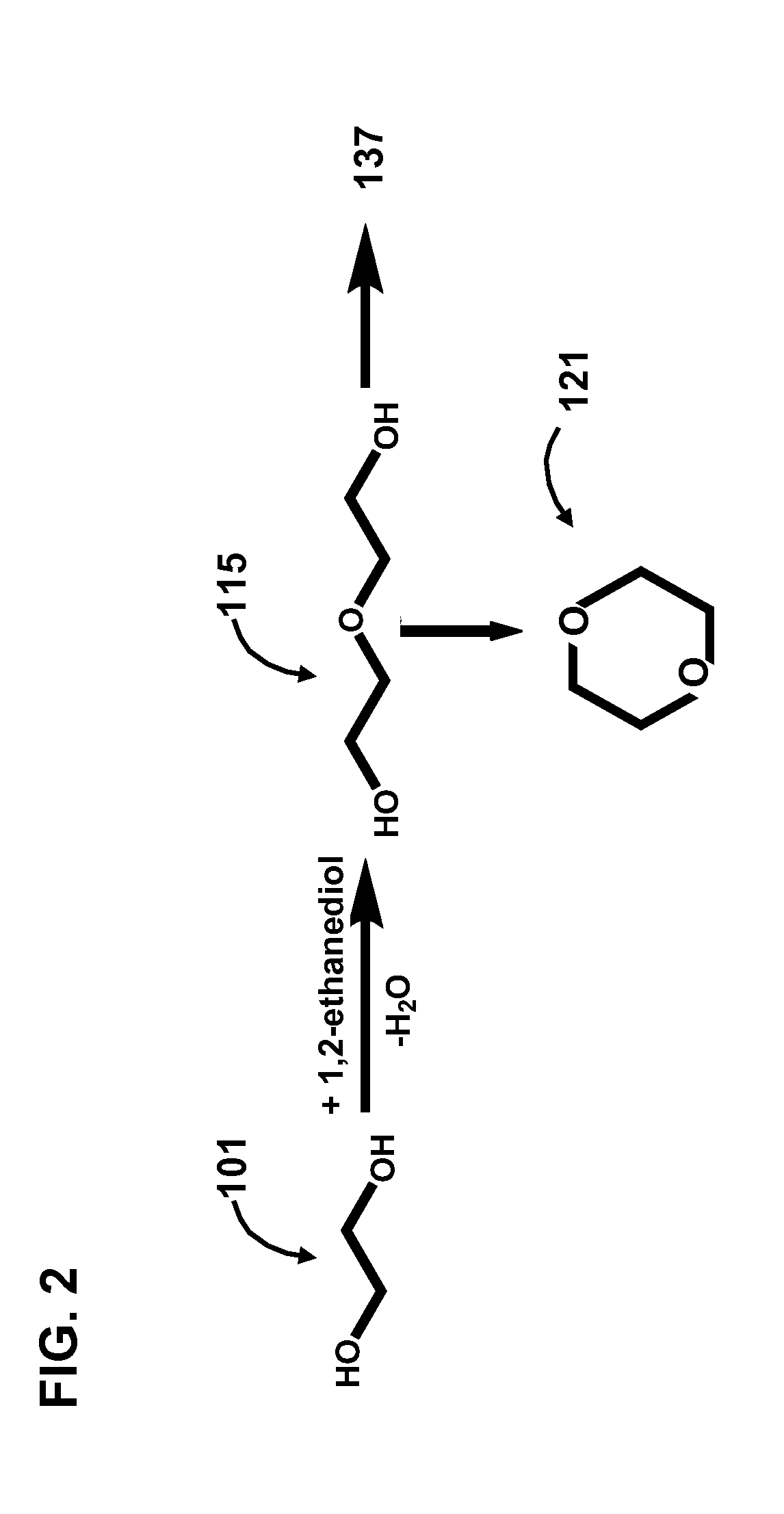

Condensation of glycols to produce biofuels

ActiveUS8617262B2Easy to usePrevent degradationMolecular sieve catalystsCatalyst activation/preparationBiofuelOrganic chemistry

Owner:PHILLIPS 66 CO

Process for preparing and separating monodisperse polyethylene glycol

InactiveUS9630903B2Wide sourceLow costPreparation from carboxylic acid halidesEther separation/purificationPolyethylene glycol productOrganic solvent

Owner:NANJING CARBONDE TECH +1

Aquarium fish feed and preparation method thereof

InactiveCN111248363ARegulate immunityImprove immunityClimate change adaptationAnimal feeding stuffBiotechnologyYolk

The invention provides aquarium fish feed. The aquarium fish feed is prepared from the following raw materials in parts by weight: 10-15 parts of bloodworms, 5-10 parts of fly maggots, 3-8 parts of silkworm chrysalis, 5-15 parts of cooked egg yolks, 15-20 parts of cooked pork livers, 15-25 parts of nostoc sphaeroides, 5-10 parts of haematococcus pluvialis, 3-7 parts of corns, 10-15 parts of pectin, 1-3 parts of preservative, 2-4 parts of vitamin complex, 1-3 parts of mineral complex, 20-40 parts of water and 30-50 parts of polyethylene glycol 3350. The nostoc sphaeroides, haematococcus pluvialis and other algae raw materials are added into the aquarium fish feed, so that pigment raw materials, such as phycobiliprotein, are increased in the feed, the phycobiliprotein can colorize the fish body to improve the ornamental value and can be used for regulating the immunity, delaying senescence, enhancing the immunity of fish and prolonging lives of fish.

Owner:湖南振鑫农业科技有限公司

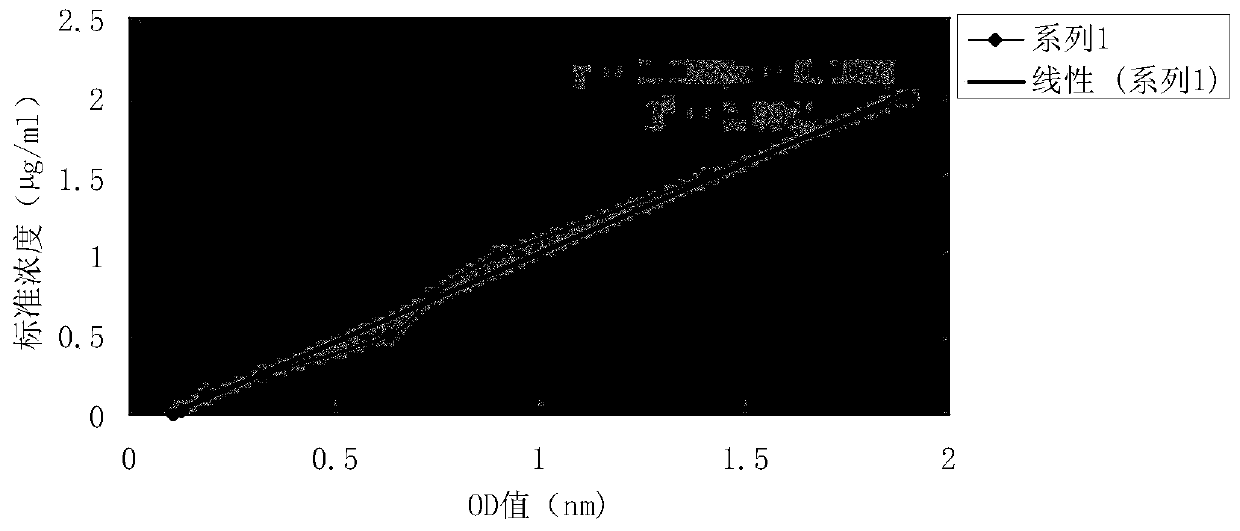

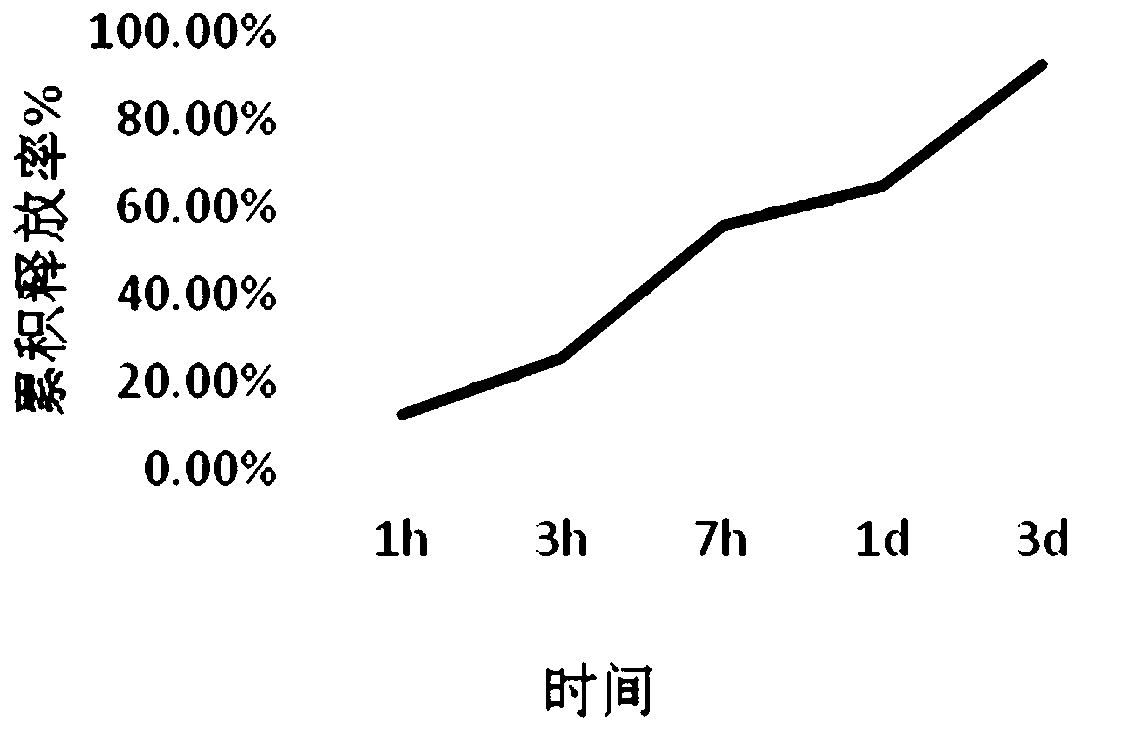

Pharmaceutical composition for relaxing bowels and purging intestines and preparation method of pharmaceutical composition

ActiveCN102600201BPrecise control of molecular weight distributionGood for cleaning preparationMetabolism disorderDigestive systemIntestinal structurePolyethylene glycol product

Owner:STAIDSON (BEIJING) BIOPHARMACEUTICALS CO LTD

Water-soluble composite immunoadjuvant and application thereof

ActiveCN111467488AGuaranteed stabilityImprove stabilityAntibacterial agentsBacterial antigen ingredientsDiseaseLevamisole

The invention provides a water-soluble composite immunoadjuvant and a foot-and-mouth disease composite water adjuvant inactivated vaccine. The water-solubility composite immunoadjuvant comprises 0.5-0.6% of carbomer,1%-3% of levamisole,1-2% of trehalose, 0.3-2% of raffinose, 0.5-1.5% of glucan, 0.5-1.5% of sorbitol, 0.5-1% of mannitol, 0.5-1.5% of xylitol, 0.2-2% of polyethylene glycol 3350, and 1-5% of D-alpha-Tocopheryl polyethylene glycol 1000 succinate. The water-solubility composite immunoadjuvant is free from mineral oil, easy to absorb by organisms, and small in tissue damage and stressreaction. The invention further relates to an application of the foot-and-mouth disease composite water adjuvant inactivated vaccine to freeze-dry vaccine combined immunization.

Owner:内蒙古必威安泰生物科技有限公司

Lateral line rectification separation method for organic components of polyethylene glycol, ethylene glycol and ethylene glycol monomethyl ether in crystalline silicon cutting mixing recovery liquid

ActiveCN102643173BOptimizing Process ParametersEther separation/purificationOrganic compound preparationPolymer scienceReboiler

The invention provides a lateral line rectification separation method for organic components of polyethylene glycol, ethylene glycol and ethylene glycol monomethyl ether in crystalline silicon cutting mixing recovery liquid, which comprises the following steps of: (1) taking moisture-free crystalline silicon cutting mixing recovery liquid as raw material, and pumping into a lateral line fractionating tower; (2) carrying out fraction at 124-125 DEG C in a cutting way on the top of the tower, controlling reflux ratio, and recovering an ethylene glycol monomethyl ether product from the top of the tower to enter into an ethylene glycol monomethyl ether storing tank; (3) carrying out fraction at 195-200 DEG C in a cutting way at the lateral line on the upper part of the tower, exchanging heat by a heat exchanger to be taken as an ethylene glycol product to enter into a storing tank; and (4) reheating material on a tower kettle by a reboiler, controlling the temperature to be in a range of 240 DEG C to 245 DEG C, cooling some material to be taken as a polyethylene glycol product to enter into a polyethylene glycol product storing tank. The method adopts optimized technology parameters, and adopts the lateral line of a single tower to separate three components in the crystalline silicon cutting mixing recovery liquid in a rectifying way. The ethylene glycol monomethyl ether is recovered from the top of the tower, the ethylene glycol is recovered from the lateral line, and the polyethylene glycol is obtained from the tower kettle. Due to single-tower operation, the equipment cost and the energy consumption can be reduced compared with those of the conventional method.

Owner:JIANGSU YINGTIAN CHEM

Silicon wafer-cutting waste slurry recovery method

ActiveCN102643710BRealize environmentally friendly emissionsEliminate acid and alkali washing processSilicon carbideLubricant compositionPolyethylene glycol productCarbide silicon

Owner:泗阳瑞泰光伏材料有限公司

Process for treating chlorinated organic compounds by polyethylene glycol and alkaline substances

InactiveCN102921144BAchieve dechlorination degradationAchieve complete dechlorination degradationChemical protectionPolyethylene glycol productReaction temperature

The invention discloses a process for treating chlorinated organic compounds by polyethylene glycol and alkaline substances. Wastes containing chlorinated organic pollutants are added into a reactor, the polyethylene glycol and the alkaline substances are sequentially added into the reactor, and dechlorination degradation reaction can be achieved. The process has the advantages that the reaction time is short, the reaction temperature is low and the reaction materials are easy to obtain.

Owner:TSINGHUA UNIV

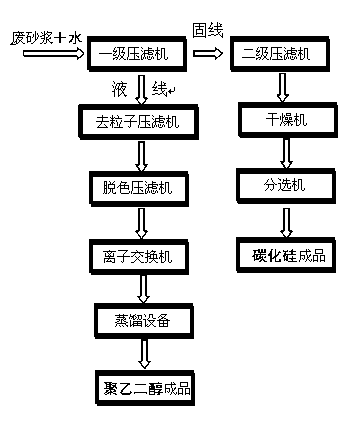

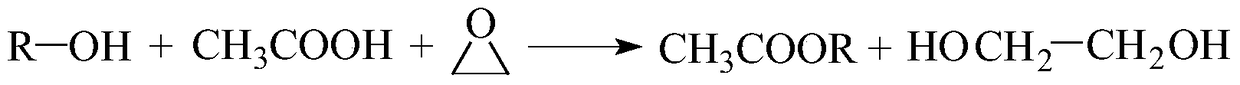

Coproduction method of acetate and ethylene glycol

ActiveCN106146298BEmission reductionReduce investmentOrganic compound preparationChemical industryAcetic acidPolyethylene glycol product

The invention relates to a co-production method of acetate and ethylene glycol. The technical problems that due to the fact that existing acetate production process produced water forms multiple types of azeotrope, the workflow is complex, and energy consumption of separation is high are mainly solved. According to the technical scheme, on the condition that a catalyst exists, acetic acid is added into the upper portion inside a single reactive distillation tower, at least one of C1-C5 alcohols and ethylene oxide are added into the lower portion inside the single reactive distillation tower, acetic acid and alcohols are subjected to an esterification reaction, and acetate and water are generated; ethylene oxide reacts with water generated through the esterification reaction to generate ethylene glycol, and an acetate mixture is obtained on the top of the reactive distillation tower; the acetate mixture is further subjected to distillation separation, ethylene glycol, diethylene glycol, triethylene glycol and polyethylene glycol are obtained in a reactive distillation tower kettle, and an ethylene glycol product, a diethylene glycol product, a triethylene glycol product, a polyethylene glycol product and other heavy components are obtained through distillation respectively. The problems are better solved, and the co-production method of acetate and ethylene glycol can be used for co-production industrial production of acetate and ethylene glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dinitolmide solution and preparation method thereof

InactiveCN109528643AImprove solubilityImprove performanceOrganic active ingredientsPharmaceutical delivery mechanismPolyethylene glycol productEucalyptus oil

The present invention discloses a dinitramine solution. The dinitramine solution comprises the following raw materials in parts by weight: 10-20 parts of dinitramine, 75-95 parts of polyethylene glycol-3350, 5-10 parts of a suspending agent, 1-3 parts of eucalyptus oil, 8-13 parts of a stabilizer, 3-6 parts of a preservative and 4-8 parts of a surfactant. The present invention also discloses a preparation method of the dinitramine solution. The polyethylene glycol-3350 is use and can better dissolve dinitramine. Besides, quantitative ratios of the suspending agent, eucalyptus oil, stabilizer,preservative and surfactant are added, so that the prepared dinitramine solution is obviously improved in performances and easy to absorb, drug effects can be fully utilized, and the dinitramine solution can be stored for a long time and is stable in the drug effects and favorable for popularization and application.

Owner:广东新科农生物科技有限公司

Waste silicon wafer-cutting fluid processing method and silicon carbide rinsing device

InactiveCN101857229BReduce the amount addedReduce environmental disposal costsSilicon carbideMaterials scienceSodium hydroxide

The invention discloses a waste silicon wafer-cutting fluid processing method and a silicon carbide rinsing device. The processing method includes the following steps that: (A) water is added to dilute waste silicon wafer-cutting fluid and mixed, and a magnet is used for attracting iron; (B) flocculant is added, and solid and liquid are separated; (C) water is added to dilute the solid, and the silicon carbide suspension is added with sodium hydroxide, heated for reaction, washed by water, added with acid and washed until the pH value reaches 6.5 to 7, so that a crude silicon carbide product is obtained; (D) the crude product is separated, and after drying, a finished silicon carbide product is obtained; (E) the liquid is filtered, and after dehydration, a finished polyethylene glycol product is obtained. The scheme increases the purity of the sodium carbide, and reduces the consumption of acid and alkaline. The silicon carbide rinsing device comprises a rinsing bucket, the sidewall of the rinsing bucket is provided with a plurality of decanting outlets, the end of the rinsing bucket is provided with a water inlet tube, and a water distributor is arranged in the cone; the wall of the rinsing bucket is also provided with an air inlet, and an air tube is arranged in the bucket, and is provided with a plurality of microporous air distributors. The device can prevent the sediment of silicon carbide, thus enhancing the rinsing effect.

Owner:ZHEJIANG YUANSHENG SILICON MATERIALS

Refining method of polyethylene glycol containing ethylene oxide impurities

ActiveCN104262613AEfficient removalComply with pharmaceutical grade requirementsPolyethylene glycol productHydrogen

The invention provides a refining method of polyethylene glycol containing ethylene oxide impurities. According to the method, the ethylene oxide impurities are removed through an ethoxylation reaction of a to-be-refined polyethylene glycol crude product and an initiator containing reactive hydrogen under the existence of a high-activity ethoxylation reaction unit, so that refined polyethylene glycol is obtained, wherein the high-activity ethoxylation reaction unit is selected from metal salt of triethylene glycol, tetraethylene glycol or polyethylene glycol. According to the refining method provided by the invention, trace ethylene oxide impurities in a polyethylene glycol product can be effectively removed, so that the content of the ethylene oxide impurities is reduced to be lower than 1 ppm, and the medical level requirement is met; new impurities cannot be introduced with the refining method, the quality of the polyethylene glycol product is guaranteed, the product batch repeatability is good, and the product quality is stable; and the refining method is short in reaction time, mild in condition, simple to operate, environment-friendly, high in production efficiency, low in cost and very suitable for industrial application.

Owner:辽宁奥克药业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com