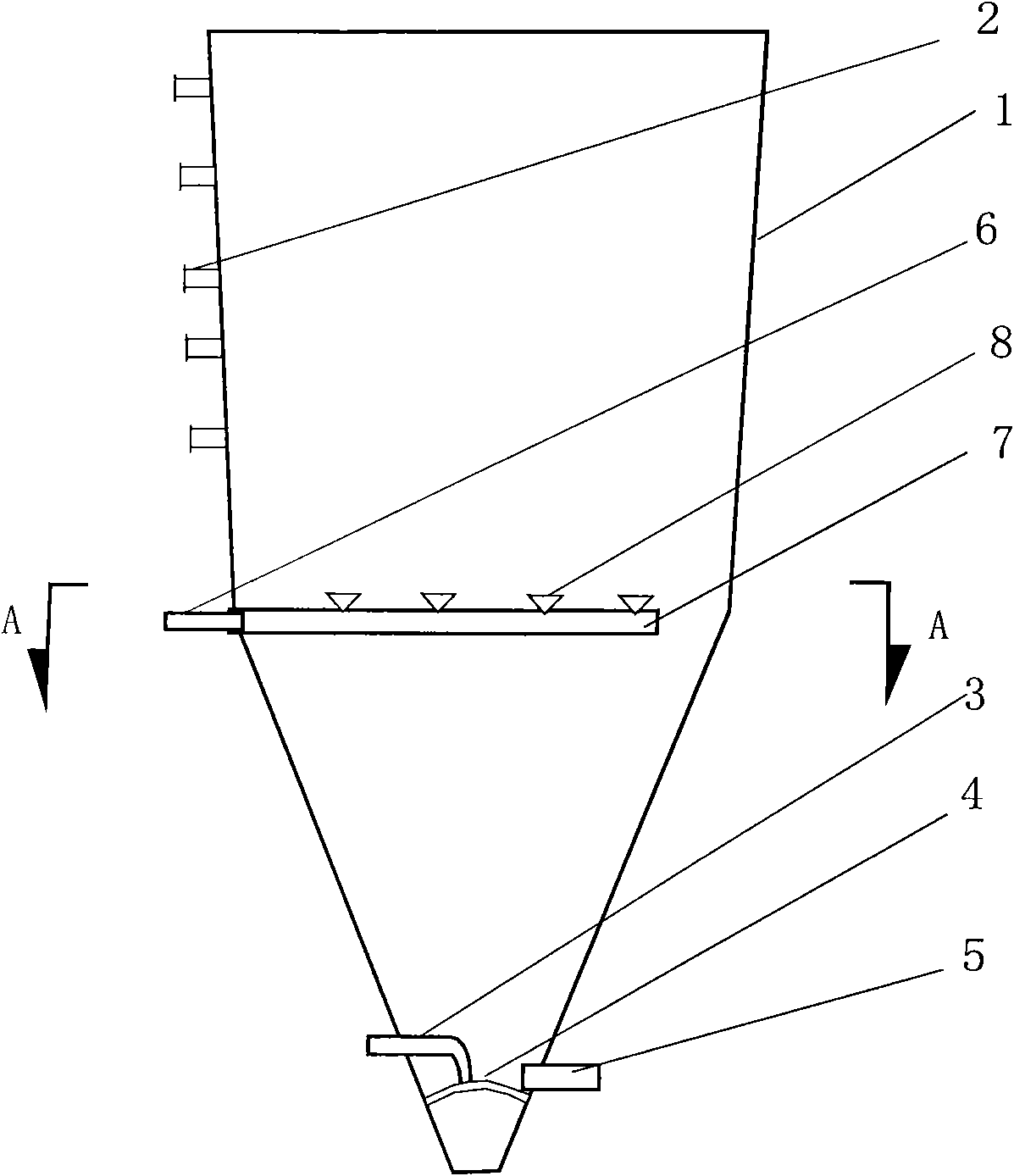

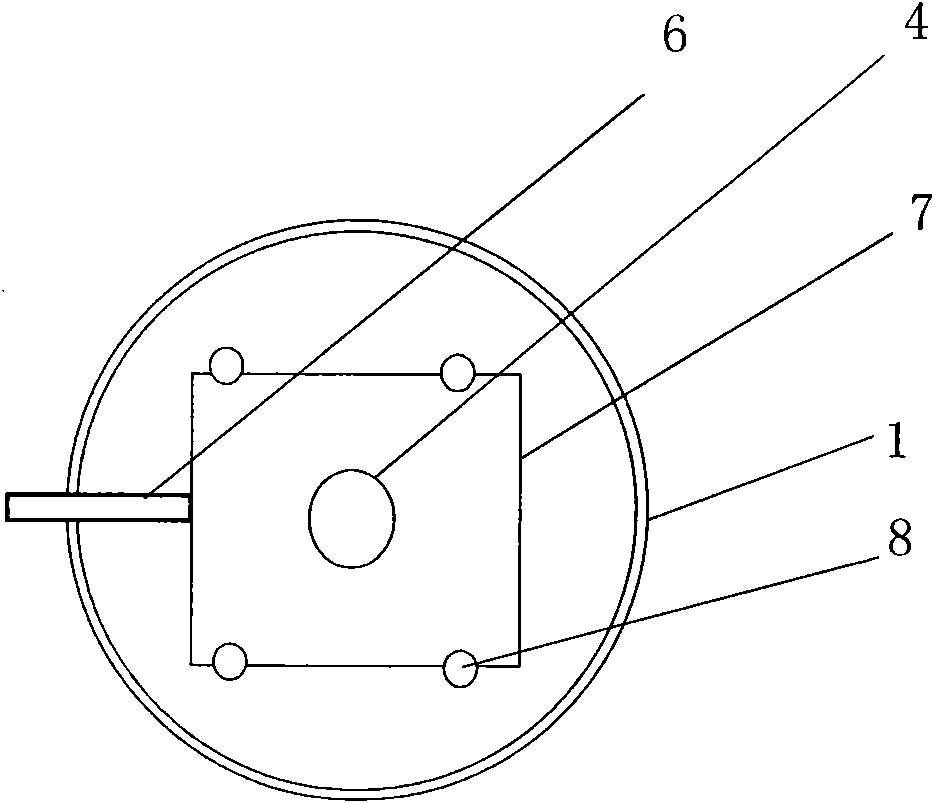

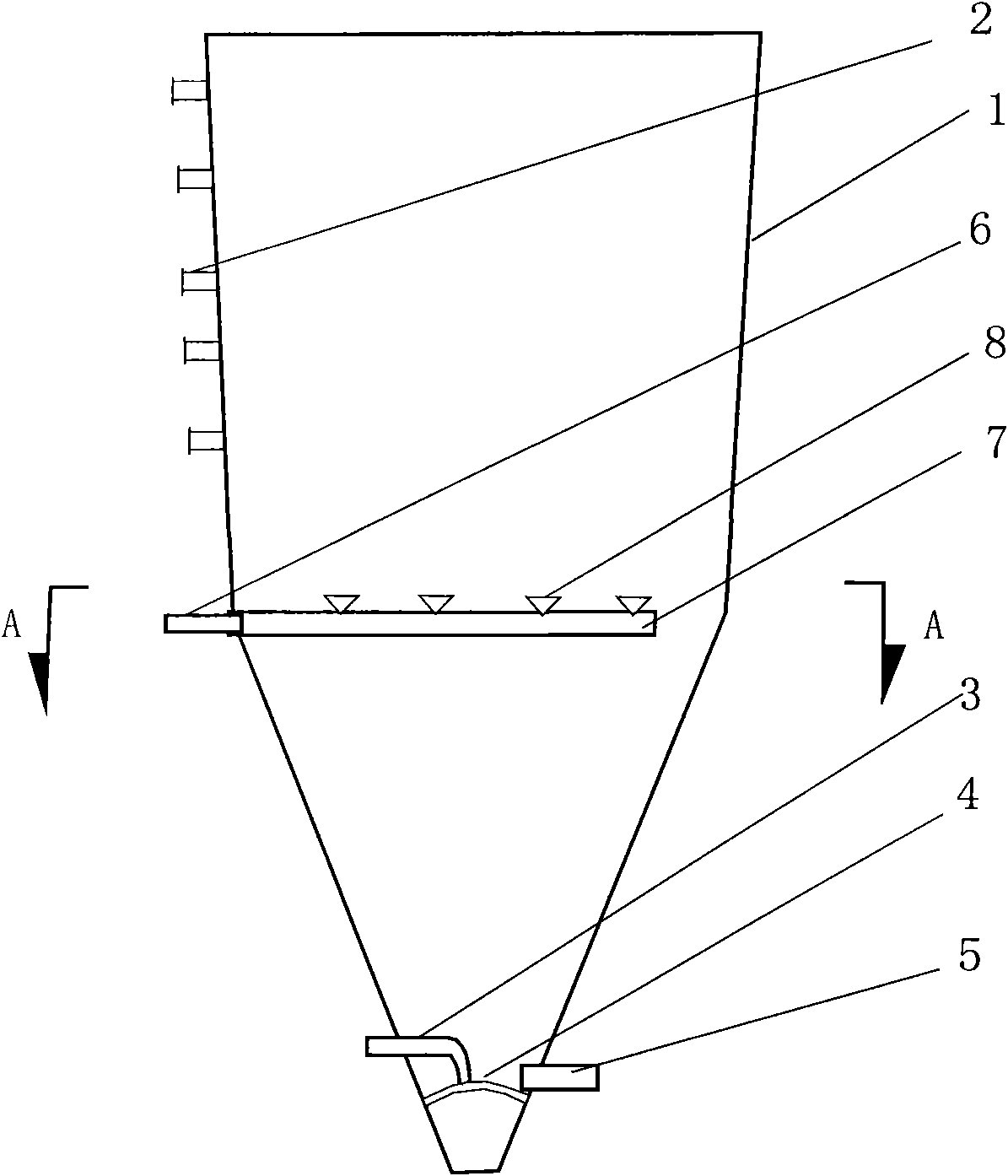

Waste silicon wafer-cutting fluid processing method and silicon carbide rinsing device

A treatment method, silicon carbide technology, applied in the direction of silicon carbide, carbide, etc., can solve the problems of ineffective separation of silicon carbide and silicon, fluorine pollution, loss of use value, etc., to achieve mature and reliable production process, high recovery rate, and treatment low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take 50 kg of silicon crystal cutting waste liquid, add 50 kg of water, stir, the mixture is ultrasonically treated, and the iron in the mixture is sucked out with a magnet; 0.03 kg of flocculant is added, and after the reaction, a centrifuge is used for solid-liquid separation to obtain a solid and liquid.

[0040] Take 10 kg of solid matter, add 10 kg of water to dilute it into a silicon carbide suspension, add a mass percent concentration of 30% sodium hydroxide solution to the suspension until the pH value is 12, heat to 80°C for reaction, and after the reaction is completed, Washing with water until the pH value reaches 7.5, then adding a 30% mass percent sulfuric acid solution until the pH value is 3, washing with water until the pH value reaches 7, and obtaining a crude silicon carbide. A scraper centrifuge is used for separation, and the separated solid is heated and dried until the water content is not more than 0.4%, and the silicon carbide product is obtained...

Embodiment 2

[0043]Take 50 kg of silicon crystal cutting waste liquid, add 100 kg of water, stir, the mixture is ultrasonically treated, and the iron in the mixture is sucked out with a magnet; 0.05 kg of flocculant is added, and after the reaction, a centrifuge is used for solid-liquid separation to obtain a solid and liquid.

[0044] Take 10 kg of solid matter, add 15 kg of water to dilute it into a silicon carbide suspension, add a mass percent concentration of 40% sodium hydroxide solution to the suspension until the pH value is 11, and heat to 90°C for reaction. After the reaction is completed, Washing with water until the pH value reaches 7, then adding a 25% hydrochloric acid solution by mass percentage until the pH value is 1, washing with water until the pH value reaches 6.5, and obtaining a crude silicon carbide. A scraper centrifuge is used for separation, and the separated solid is heated and dried until the water content is not more than 0.5%, so as to obtain a finished silico...

Embodiment 3

[0047] Take 50 kg of silicon crystal cutting waste liquid, add 25 kg of water, stir, the mixture is ultrasonically treated, and the iron in the mixture is sucked out with a magnet; 0.01 kg of flocculant is added, and after the reaction, a centrifuge is used for solid-liquid separation to obtain a solid and liquid.

[0048] Take 10 kg of solid matter, add 5 kg of water to dilute it into a silicon carbide suspension, add a mass percent concentration of 10% sodium hydroxide solution to the suspension until the pH value is 13, heat to 60°C for reaction, and after the reaction is completed, Washing with water until the pH value reaches 7, then adding a 20% sulfuric acid solution by mass percentage until the pH value is 4, washing with water until the pH value reaches 7, and obtaining a crude silicon carbide. A scraper centrifuge is used for separation, and the separated solid is heated and dried until the water content is not more than 0.3%, so as to obtain a finished silicon carbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com