Lateral line rectification separation method for organic components of polyethylene glycol, ethylene glycol and ethylene glycol monomethyl ether in crystalline silicon cutting mixing recovery liquid

A technology of ethylene glycol monomethyl ether and polyethylene glycol, applied in ether separation/purification, preparation of organic compounds, organic chemistry, etc. Cost, energy consumption and other problems, to achieve the effect of saving equipment cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

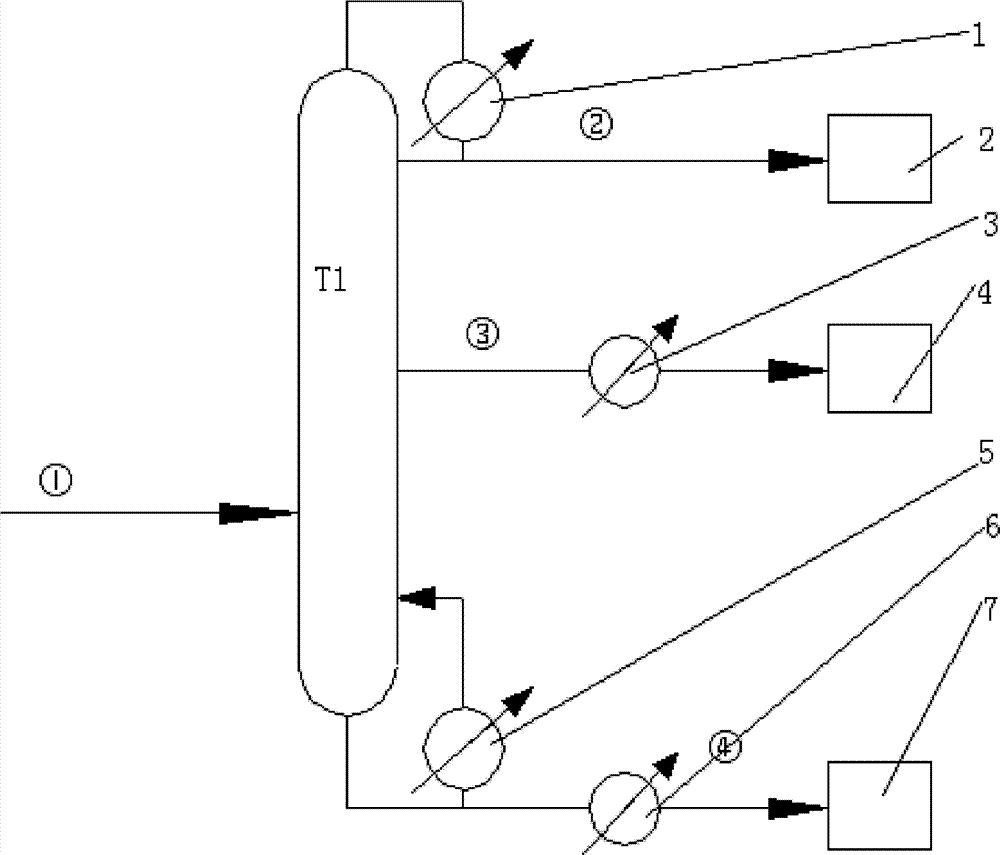

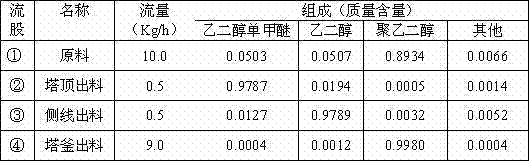

[0015] Embodiment 1, the method for side line rectification separation of organic components in crystalline silicon cutting mixed recovery liquid, refer to figure 1 The process flow shown and the process parameters shown in Table 1, the raw material ① is the crystalline silicon cutting mixed recovery liquid after water removal, wherein the mass content of ethylene glycol monomethyl ether, ethylene glycol, and polyethylene glycol are respectively 5%, 5%, 90%, the flow rate is 10Kg / h, the absolute pressure at the top of side rectification column T1 is 1atm, the temperature is 124~125°C, the reflux ratio is controlled at about 6, and the output from the top of the tower is The flow rate is 0.5 Kg / h and the composition is x 乙二醇单甲醚 =0.9787,x 乙二醇 =0.0194,x 聚乙二醇 =0.0005, side line discharge , the temperature is 195~200℃, the flow rate is 0.5 Kg / h, and the composition is x 乙二醇单甲醚 =0.0127,x 乙二醇 =0.9789,x 聚乙二醇 =0.0032, the discharge from the tower kettle ④The flow rate is 9Kg / h,...

Embodiment 2

[0020] Example 2 is basically the same as Example 1, but the reflux ratio is controlled to be 4:1.

Embodiment 3

[0021] Example 3 is basically the same as Example 1, but the reflux ratio is controlled to be 8:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com