Coproduction method of acetate and ethylene glycol

A technology of ethylene glycol and acetate, applied in the field of co-production of acetate and ethylene glycol, can solve the problems of high separation energy consumption and complicated process, achieve good technical effects, reduce emissions, and reduce equipment investment and the effect of process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

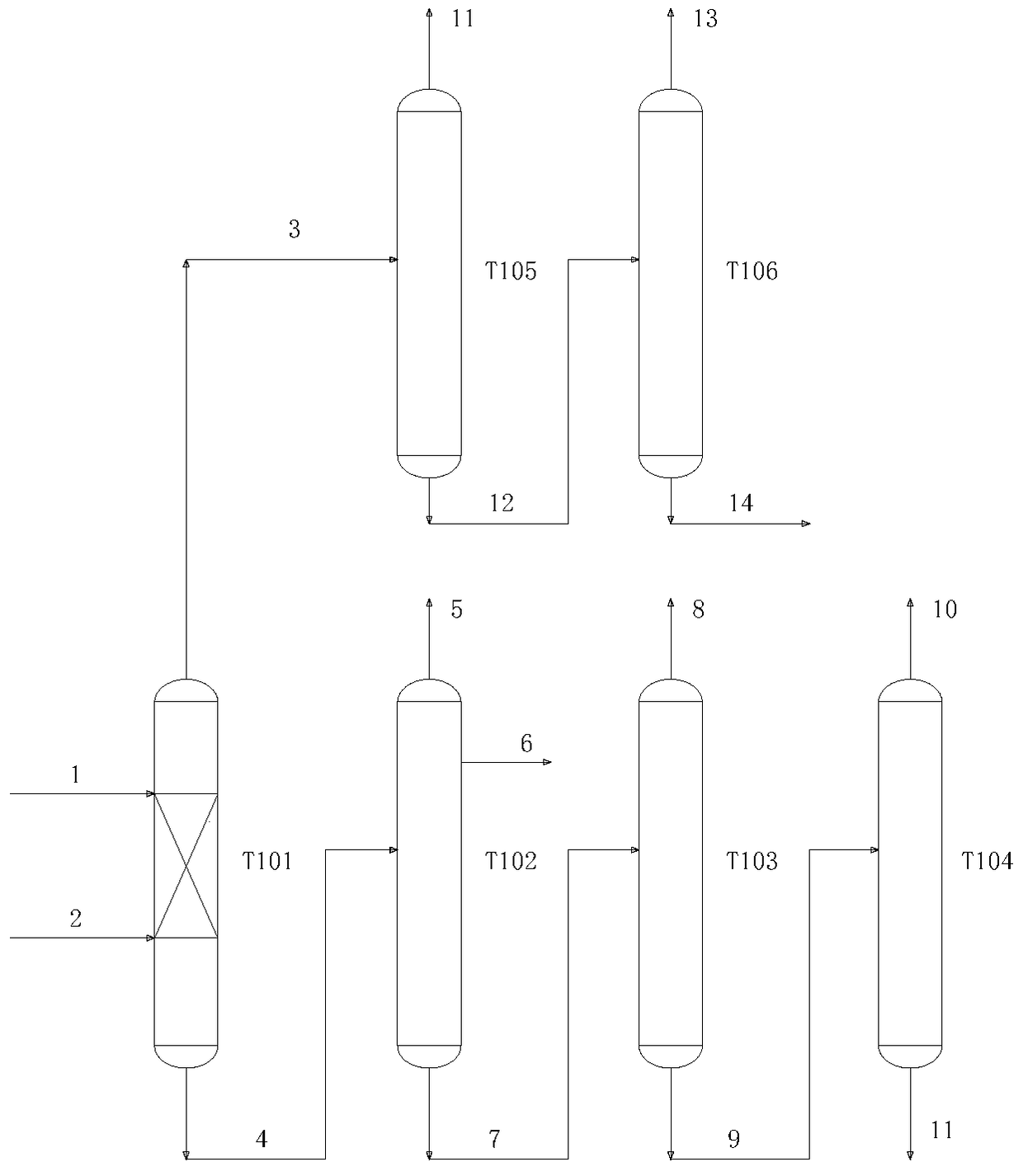

[0036] Under the condition that catalyst exists, the mixture of alcohol and oxirane reacts with acetic acid, coproduces acetate and ethylene glycol, comprises the following steps:

[0037] a) Acetic acid is added to the upper part of a single reactive distillation column, and a mixture of alcohol and ethylene oxide is added to the lower part; the rectification section is from the feed position of acetic acid to the top of the tower, between the feed position of acetic acid and the feed position of the mixture of alcohol and ethylene oxide The middle is the reaction section, and the feed position of the mixture of alcohol and ethylene oxide to the tower kettle is the stripping section;

[0038] b) The rectification section is filled with fillers, the reaction section is filled with catalysts and fillers, and the stripping section is filled with fillers;

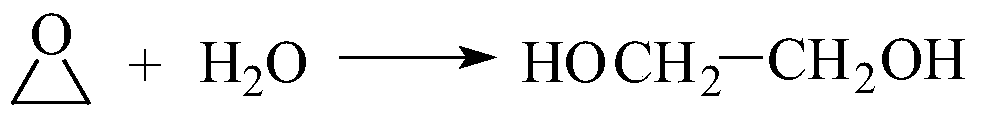

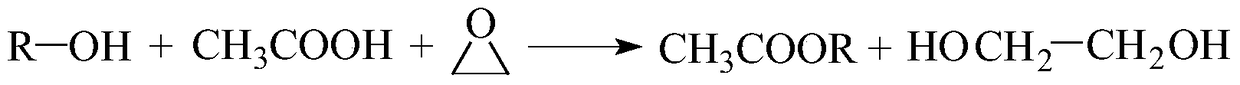

[0039] c) acetic acid and alcohol undergo esterification to generate acetate, while ethylene oxide and the water generated b...

Embodiment 2

[0051] Under the condition that catalyst exists, the mixture of alcohol and oxirane reacts with acetic acid, coproduces acetate and ethylene glycol, comprises the following steps:

[0052] a) Acetic acid is added to the upper part of a single reactive distillation column, and a mixture of alcohol and ethylene oxide is added to the lower part; the rectification section is from the feed position of acetic acid to the top of the tower, between the feed position of acetic acid and the feed position of the mixture of alcohol and ethylene oxide The middle is the reaction section, and the feed position of the mixture of alcohol and ethylene oxide to the tower kettle is the stripping section;

[0053] b) The rectification section is filled with fillers, the reaction section is filled with catalysts and fillers, and the stripping section is filled with fillers;

[0054] c) acetic acid and alcohol undergo esterification to generate acetate, while ethylene oxide and the water generated b...

Embodiment 3

[0065] Under the condition that catalyst exists, the mixture of alcohol and oxirane reacts with acetic acid, coproduces acetate and ethylene glycol, comprises the following steps:

[0066] a) Acetic acid is added to the upper part of a single reactive distillation column, and a mixture of alcohol and ethylene oxide is added to the lower part; the rectification section is from the feed position of acetic acid to the top of the tower, between the feed position of acetic acid and the feed position of the mixture of alcohol and ethylene oxide The middle is the reaction section, and the feed position of the mixture of alcohol and ethylene oxide to the tower kettle is the stripping section;

[0067] b) The rectification section is filled with fillers, the reaction section is filled with catalysts and fillers, and the stripping section is filled with fillers;

[0068] c) acetic acid and alcohol undergo esterification to generate acetate, while ethylene oxide and the water generated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com