Polyethylene glycol sodium potassium powder and preparation method thereof

A technology of polyethylene glycol sodium potassium powder and polyethylene glycol, which is applied in the field of medicine and biology, can solve the problems of poor fluidity, poor content uniformity, and large difference in loading of the blend, so as to achieve good fluidity and improve fluidity , the effect of reducing the difference in loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

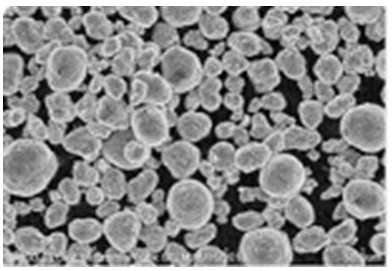

[0035] see figure 1 , a preparation method of polyethylene glycol sodium potassium powder, comprising the following steps:

[0036] Step 1. Preparation of solution I: Add polyethylene glycol 3350 into a hot pot, heat and melt at 60°C to obtain solution I.

[0037] Step 2, preparation of solution II: take sodium chloride, potassium chloride, sodium bicarbonate and sweetener, add 3 times the amount of purified water at a temperature of 60° C., stir to dissolve and clarify, and obtain solution II.

[0038] Step 3, preparation of solution III: adding solution II to solution I, stirring and mixing evenly, stirring for 10 minutes, heating at 60° C. to obtain mixed solution III.

[0039] Step 4, Spray drying: Turn on the spray drying tower fan, set the fan frequency of the spray drying tower fan to 50Hz, let in natural wind, and the natural wind temperature is 25°C, spray solution Ⅲ into the spray tower, adjust the flow rate, and make the spray fine In the fog state, after all spra...

Embodiment 2

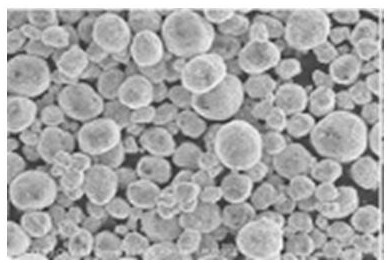

[0052] see figure 2 , on the basis of embodiment 1, the difference of the preparation method in the present embodiment and embodiment 1 is as follows:

[0053] A preparation method of polyethylene glycol sodium potassium powder, comprising the following steps:

[0054] Step 1. Prepare solution I: add polyethylene glycol 3350 into a hot pot, heat and melt at a temperature above 60°C to obtain solution I.

[0055] Step 2, preparation of solution II: take sodium chloride, potassium chloride, sodium bicarbonate and sweetener, add 3 times the amount of the temperature to 70 ° C, stir to dissolve and clarify, and obtain solution II.

[0056] Step 3, preparation of solution III: add solution II to solution I, stir and mix evenly for 15 minutes, then heat at 65° C. to obtain mixed solution III.

[0057] Step 4, Spray drying: Turn on the spray drying tower fan, set the fan frequency of the spray drying tower fan to 50HZ, let in natural wind, the natural wind temperature is 20°C, spr...

Embodiment 3

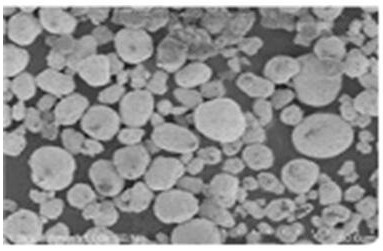

[0062] see image 3 , on the basis of embodiment 1, the difference of the preparation method in the present embodiment and embodiment 1 is as follows:

[0063] A preparation method of polyethylene glycol sodium potassium powder, comprising the following steps:

[0064] Step 1. Prepare solution I: add polyethylene glycol 3350 into a hot pot, heat and melt at a temperature above 60°C to obtain solution I.

[0065] Step 2, preparation of solution II: take sodium chloride, potassium chloride, sodium bicarbonate and sweetener, add 3 times the amount of the temperature to 75 ° C, stir to dissolve and clarify, and obtain solution II.

[0066] Step 3. Prepare solution III: add solution II to solution I, stir and mix evenly for 20 minutes, then heat at 70° C. to obtain mixed solution III.

[0067] Step 4, Spray drying: Turn on the spray drying tower fan, set the fan frequency of the spray drying tower fan to 50HZ, let in natural wind, and the natural wind temperature is 18°C, spray s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com