Pharmaceutical composition for relaxing bowels and purging intestines and preparation method of pharmaceutical composition

A technology of composition and medicine, which is applied in the field of pharmaceutical compositions for laxative and bowel cleansing, can solve the problems of poor compliance and many adverse reactions, and achieve the effect of good effect, less adverse reactions and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

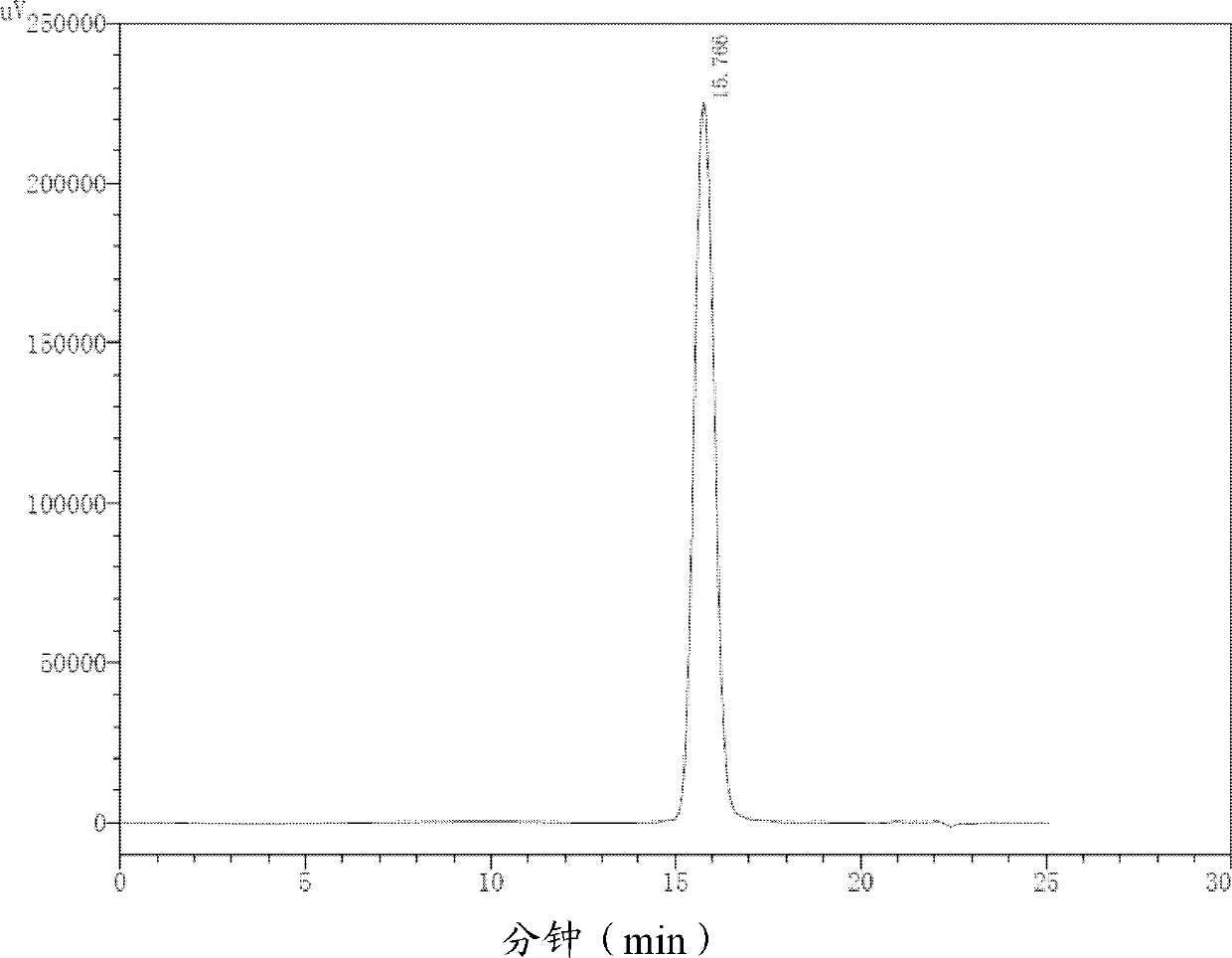

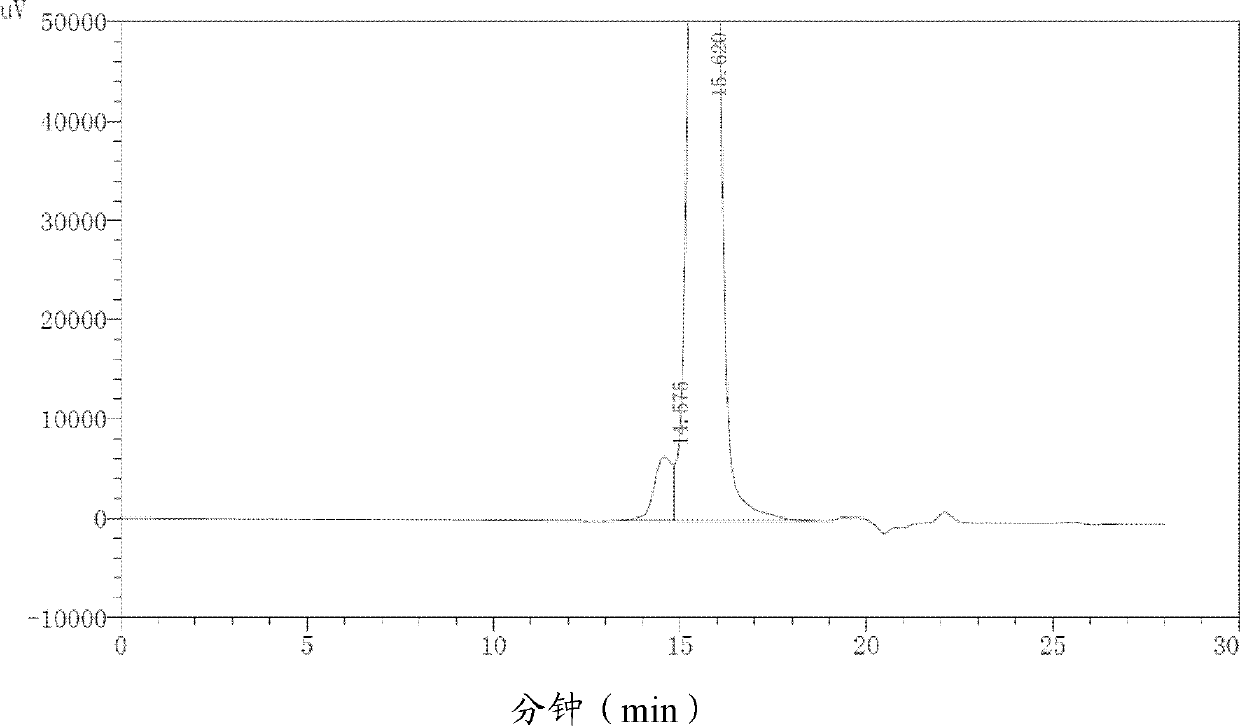

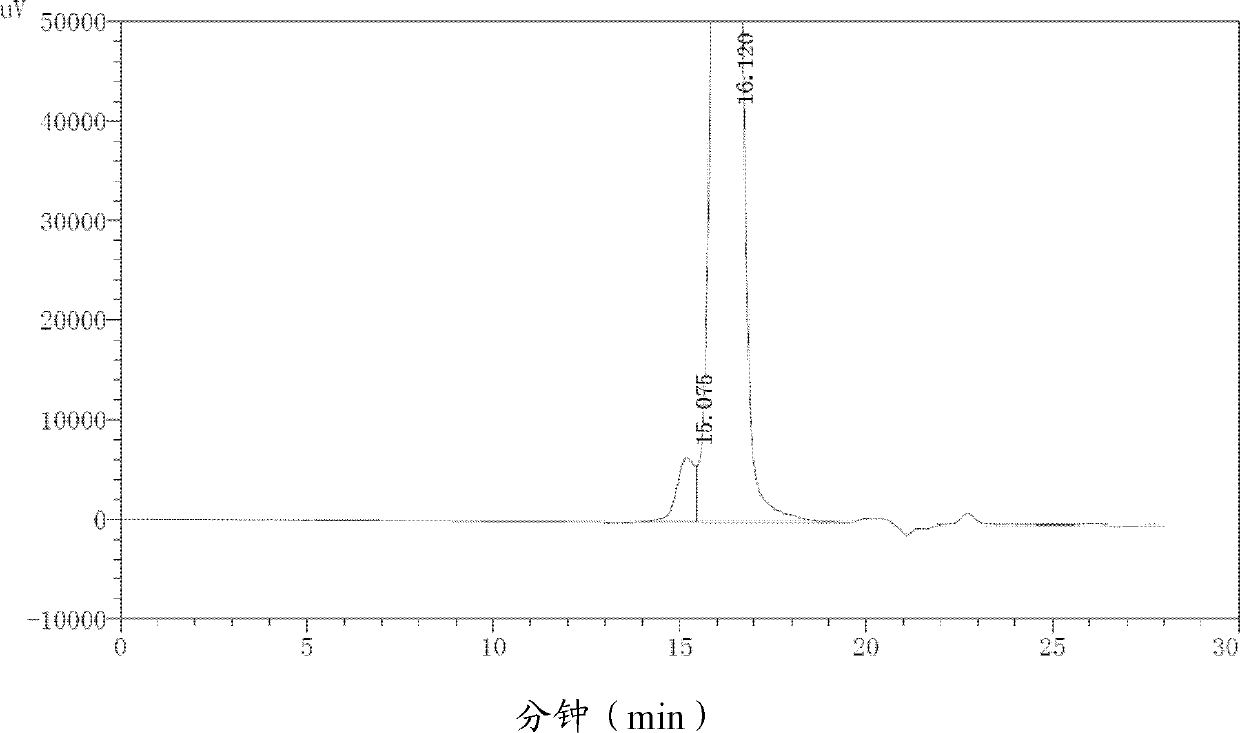

Image

Examples

preparation Embodiment 1

[0072] Under the protection of nitrogen, add 7.0L of NaOH solution to 10kg of ethylene oxide, wherein the amount of NaOH is 0.2% of the ethylene oxide in terms of molar weight, and start the reaction at 113°C under the reaction pressure of 0.23KPa .

[0073] Start timing from the addition of NaOH. After 1.5 hours of reaction, raise the temperature of the reactor to 136°C and continue the chain growth reaction. When 99% of the ethylene oxide reaction is consumed, cool down to 95°C and add 2.0L of citric acid to terminate the reaction. , the amount of citric acid in H + The molar amount is twice the molar amount of NaOH, and the obtained polyethylene glycol crude product is 9.3L.

[0074] 20 g of diatomite with a particle size of 600 μm was added to 9.3 L of the crude polyethylene glycol obtained to absorb excess reactants, and the amount of diatomite used was 0.20% by weight of ethylene oxide. The refined polyethylene glycol was filtered through a filter membrane with a pore ...

preparation Embodiment 2

[0081] Under the protection of nitrogen, add 7.0L of NaOH solution to 10kg of ethylene oxide, wherein the amount of NaOH is 0.1% of the ethylene oxide in terms of molar weight, and start the reaction at 111°C under the reaction pressure of 0.25KPa .

[0082] Start timing from the addition of NaOH, after 1.2 hours of reaction, raise the temperature of the reactor to 138°C, and continue the chain growth reaction. When 98% of the ethylene oxide reaction is consumed, cool down to 93°C, and add 3.0L of phosphoric acid to terminate the reaction. The amount of phosphoric acid in H + The molar weight is 3.0 times of the NaOH molar dosage, and the obtained polyethylene glycol crude product is 9.0 L.

[0083] 15 g of diatomite with a particle size of 800 μm was added to 9.0 L of the crude polyethylene glycol obtained to absorb excess reactants, and the amount of diatomite used was 0.15% by weight of ethylene oxide. The refined polyethylene glycol was filtered through a filter membrane...

preparation Embodiment 3

[0087] Under the protection of nitrogen, add 7.0L of NaOH solution to 10Kg of ethylene oxide, wherein the amount of NaOH is 0.3% of the ethylene oxide in molar weight, and start at 114°C under the reaction pressure of 0.2KPa reaction.

[0088] Start timing from the addition of NaOH, after 1.0 hours of reaction, raise the temperature of the reactor to 132°C, and continue the chain growth reaction. When 98% of the ethylene oxide reaction is consumed, cool down to 90°C, and add 1.5L of hydrochloric acid to terminate the reaction. The consumption of described hydrochloric acid is represented by H + The molar weight is 1.5 times of the NaOH molar dosage, and the obtained polyethylene glycol crude product is 9.5 L.

[0089] 5 g of magnesium silicate with a particle size of 800 μm was added to 9.5 L of the crude polyethylene glycol obtained to absorb excess reactants, and the amount of diatomaceous earth used was 0.05% by weight of ethylene oxide. The refined polyethylene glycol wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com