Yeast peptone and its preparation method

A technology for yeast peptone and yeast milk, applied in the field of yeast peptone and its preparation, can solve the problems of inability to precisely control the molecular weight distribution of peptone, difficult to accurately grasp the degree of hydrolysis, and achieve easy absorption and utilization, ensure quality stability, and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

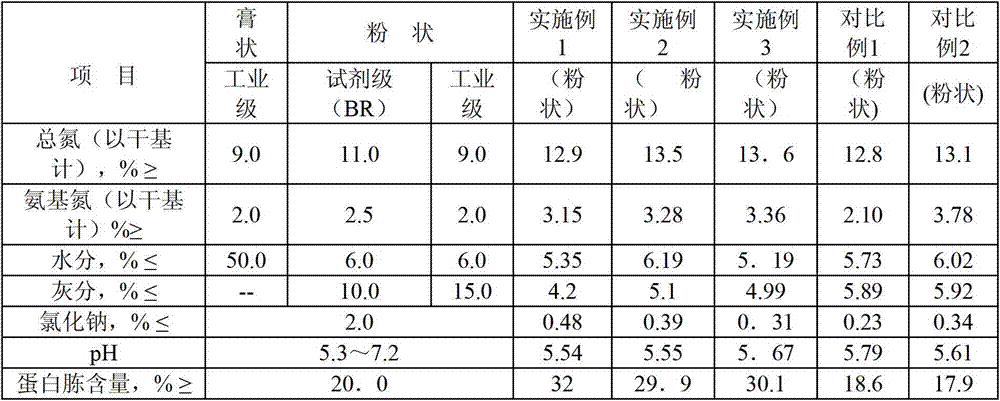

Examples

preparation example Construction

[0022] The invention provides a method for preparing yeast peptone, which includes the steps of pretreating the high-protein yeast fermented liquid, slurrying, autolyzing, enzymatic hydrolysis, centrifugal separation, enrichment by membrane filtration, and concentration and drying; wherein the molecular weight of yeast peptone The distribution is 500~3000Da. The present invention uses yeast as the raw material, avoids the disadvantages of using animal and plant sources as materials, such as transgenic, peptone products with unstable nutritional components, etc., introduces ultrafiltration technology on the basis of biological enzymatic degradation, and achieves Precisely control the molecular weight distribution of peptone to meet the standards, while maintaining a high percentage of molecular weight distribution to ensure product quality stability and meet the needs of customers in the fermentation industry. The preparation method has short production period, low cost and no ...

Embodiment 1

[0040] Take 1L of baker's yeast fermentation broth with a protein content of 50%, wash with filtered water and centrifuge three times to obtain yeast milk with a product color that meets the requirements. Add filtered water and citric acid to the yeast milk at 8°C to prepare a yeast milk suspension with a pH value of 3.6 and a yeast dry matter mass ratio concentration of 10%.

[0041] Add 20ml of ethyl acetate to the yeast milk suspension, raise the temperature to 40°C and adjust the pH value to 4, after autolysis for 5 hours, raise the temperature of the yeast milk suspension to 50°C, adjust the pH value to 6 with citric acid, add 0.6‰ of Carry out enzymolysis with papain for 18 hours to obtain an enzymolysis solution. The enzymolysis solution was heated to 70°C to terminate the enzymolysis, and then placed in a centrifuge at 4000r / min for 10 minutes to obtain the enzymolysis supernatant. Pass the enzymolysis supernatant through an organic membrane with a molecular membrane ...

Embodiment 2

[0044] Take 1L of baker's yeast fermentation broth with a protein content of 60%, wash with filtered water and centrifuge three times to obtain yeast milk with a product color that meets the requirements. At 12°C, the yeast milk was formulated with filtered water and acetic acid to obtain a yeast milk suspension with a pH value of 4.2 and a yeast dry matter concentration of 15% by mass.

[0045] Add 15ml of glyceryl monostearate to the yeast milk suspension, raise the temperature to 60°C and adjust the pH value to 6, after autolysis for 8 hours, raise the temperature of the yeast milk suspension to 60°C and adjust the pH value to 8 with acetic acid, add 0.9‰ flavor protease in the dry matter of yeast in the yeast milk suspension was hydrolyzed for 22 hours to obtain an enzymatic hydrolyzate. The enzymolysis solution was heated to 90°C to terminate the enzymolysis, and then placed in a centrifuge at 5000 r / min for 20 minutes to obtain the enzymolysis supernatant. Pass the enzy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com