Workpiece spraying device

A technology for spraying devices and workpieces, which is applied in the direction of spraying devices, devices for coating liquid on the surface, coatings, etc. It can solve the problems of endangering the health of workers, inability to spray, and uneven spraying, etc., to improve the efficiency of spraying processing, Improve the effect of spraying and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

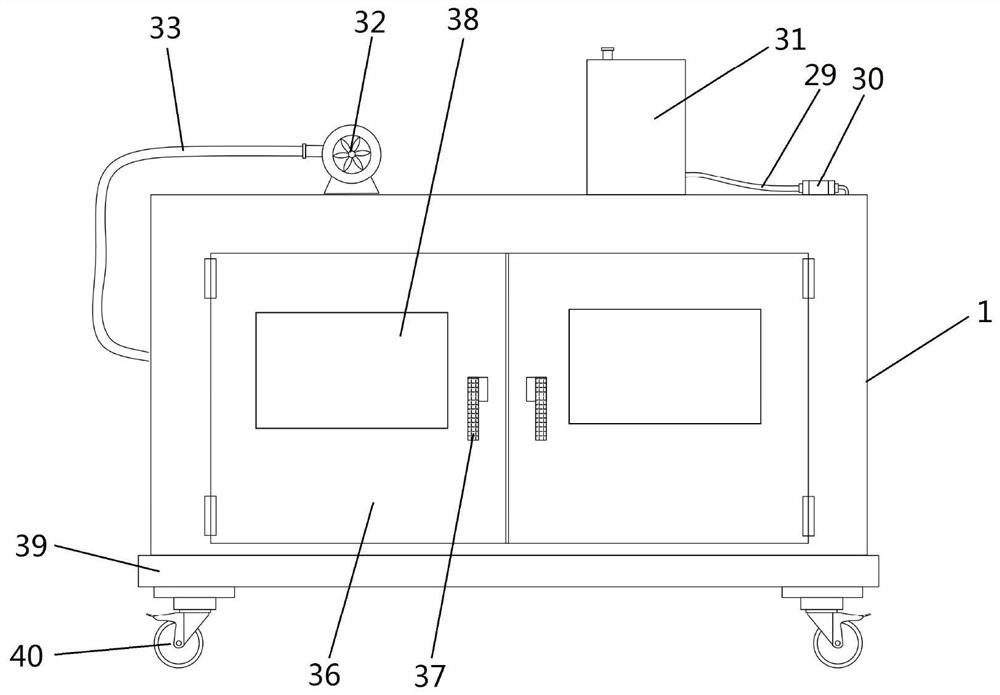

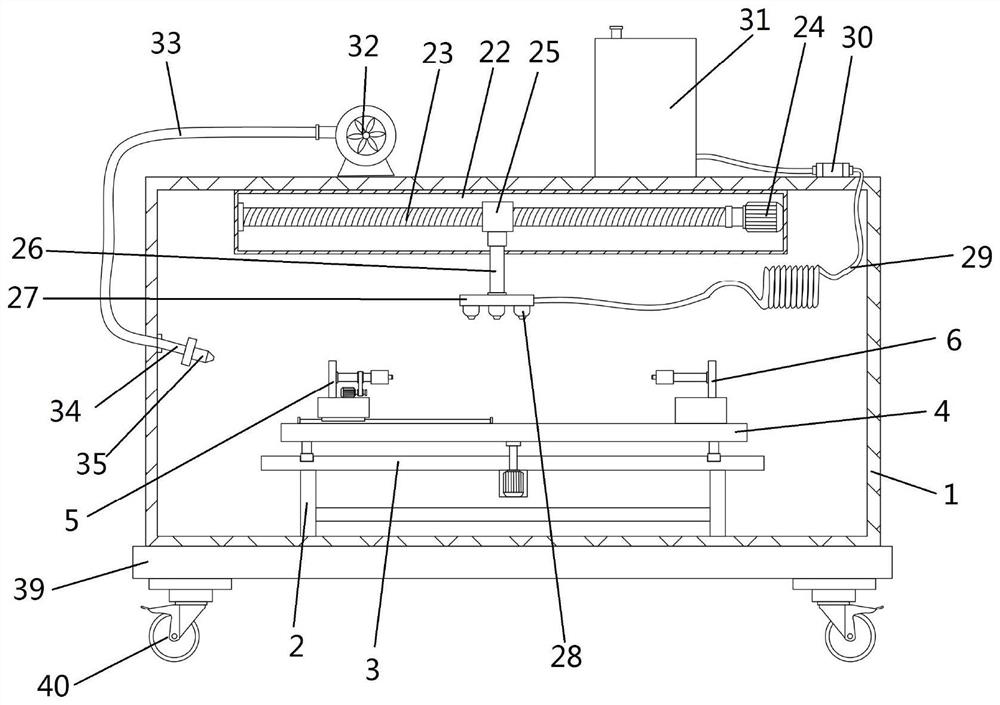

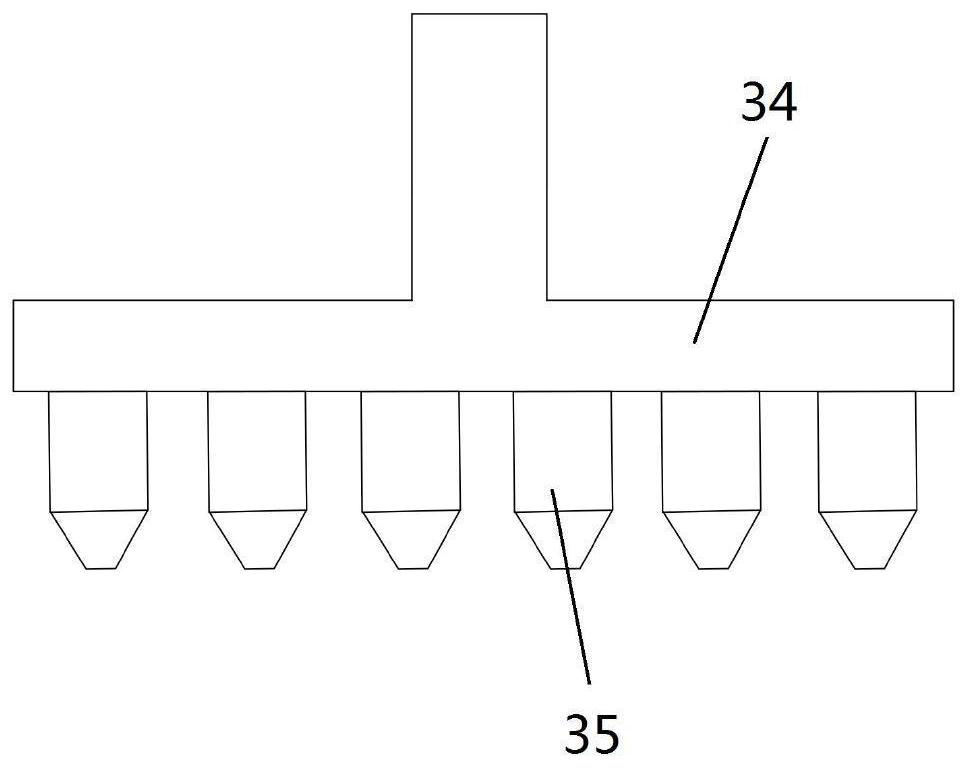

[0025] Embodiments of the present invention disclose a workpiece spraying device, such as Figure 1 to Figure 6 As shown, it includes a housing 1, a support frame body 2 is provided at the inner bottom of the housing 1, a supporting plate 3 is installed on the top of the supporting frame body 2, a rotating drive mechanism is provided on the top of the supporting plate 3, and a spraying platform 4 is provided on the rotating driving mechanism. , the rotary drive mechanism can drive the spraying platform 4 to rotate in the horizontal plane, and the opposite sides of the top of the spraying platform 4 are respectively provided with a first clamping assembly 5 and a second clamping assembly 6 for clamping and fixing the two ends of the workpiece, the first clamping The holding assembly 5 can drive the clamped workpiece to turn over and rotate along the axis under the action of the turning mechanism 13. A transmission box 22 is installed at the middle position of the top inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com