Novel preparation process of gloves and hand mold

A preparation process and glove technology, which is applied to gloves, sewing tools, clothing, etc., can solve problems such as waste of labor costs, inability to handle waste materials, pollution, etc., reduce the impact on the ecological environment, simplify the manufacturing process, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

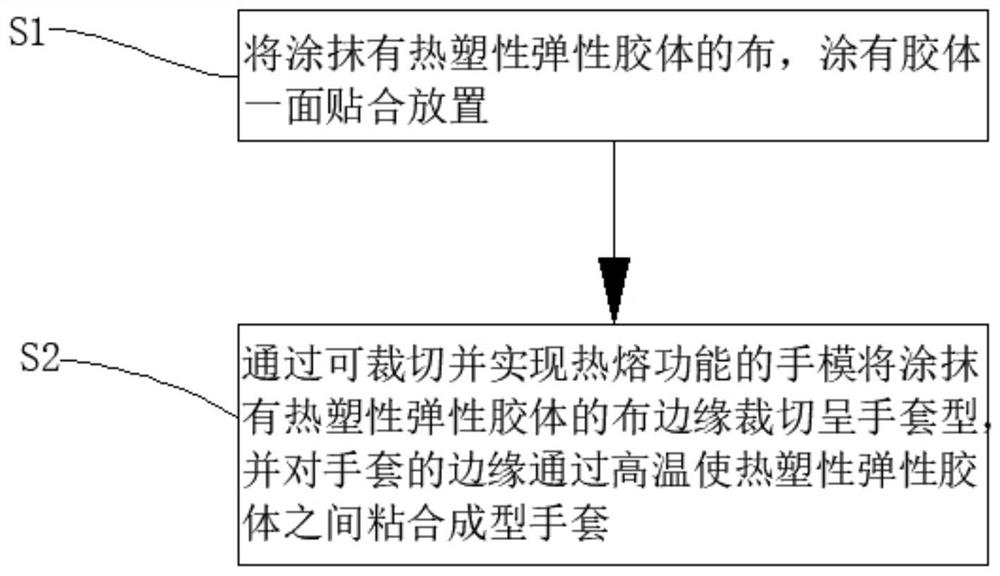

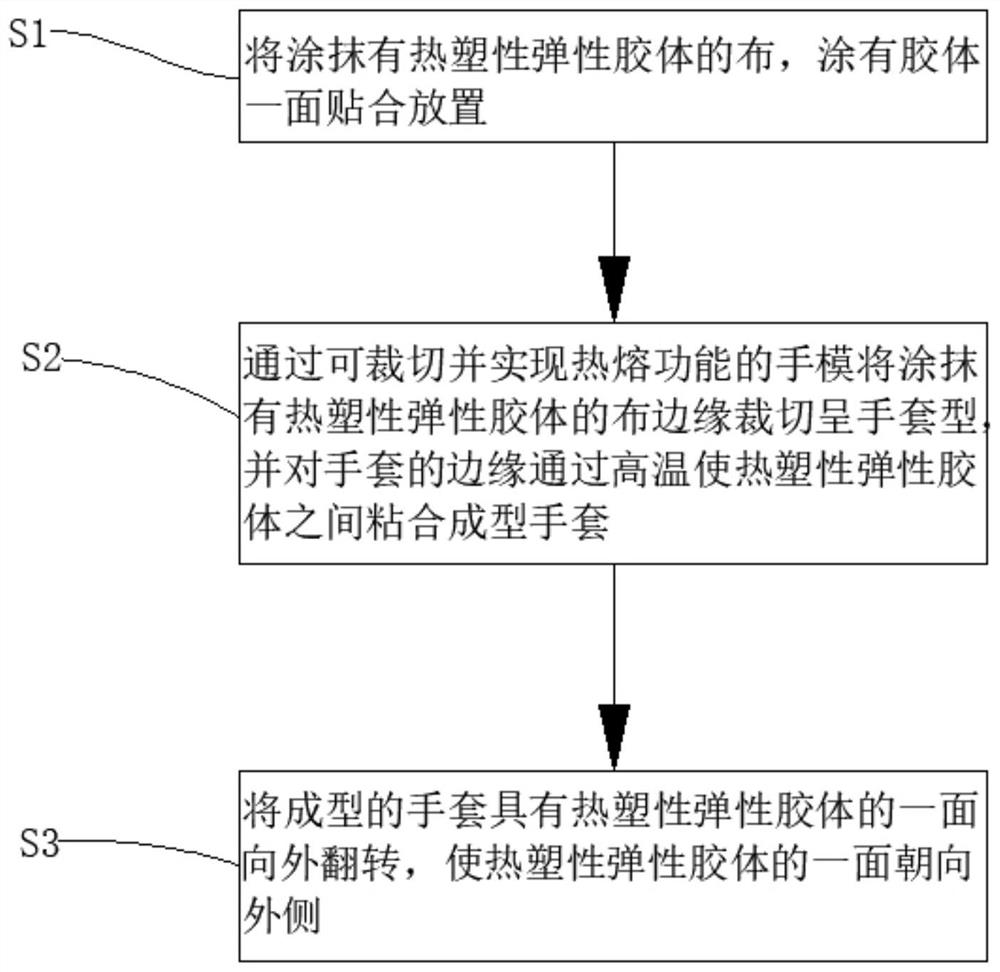

Method used

Image

Examples

Embodiment 2

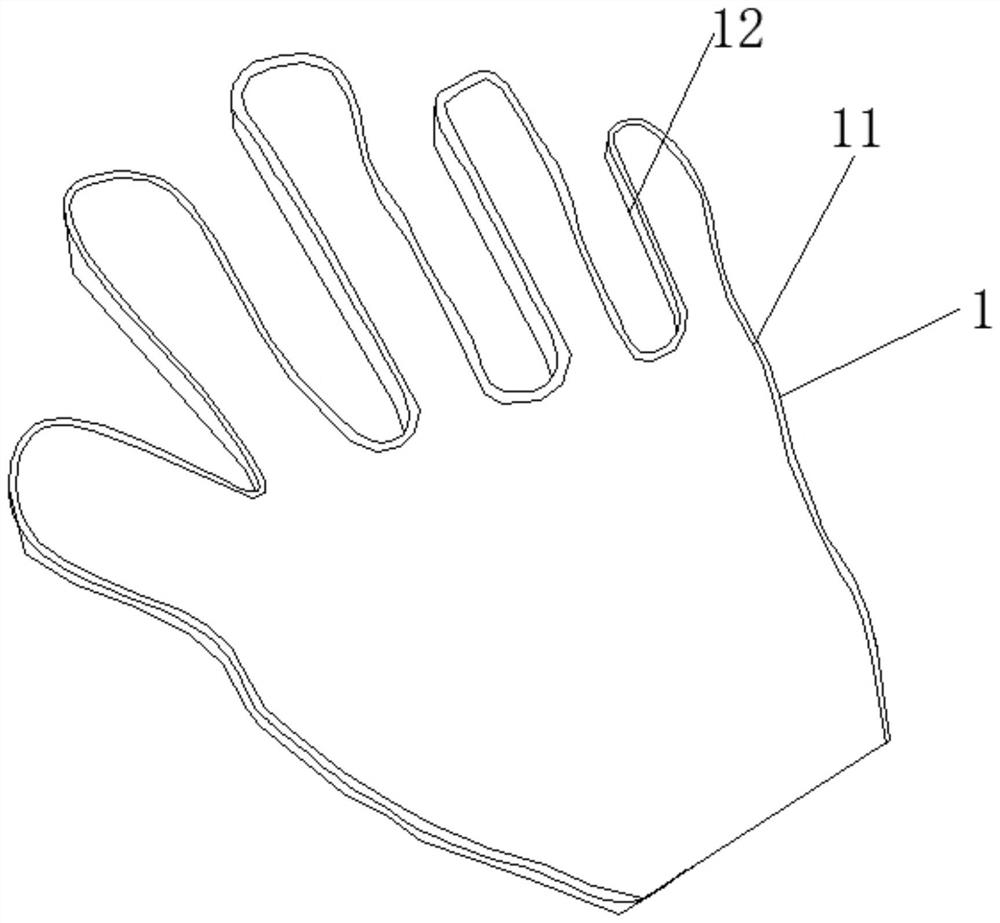

[0045] Another object of the present invention is to provide: a novel glove processing hand mold, see Figure 3-5, including the hand mold body, the cutter set at the bottom of the hand mold body, and the high-temperature fusion bonding part set on the inside of the top of the hand mold body. Through high-temperature fusion bonding, a high-temperature method is used for the edge of the glove to make the thermoplastic elastic colloid Glue the molded gloves between them, wherein the width of the high-temperature fusion bonding part is 2-3 mm, and in this embodiment, a high-temperature fusion bonding part with a width of 2.5 mm is used, and the height of the cutting knife is 3-4 mm. The height of the cutting knife used in the method is 3.5mm, and the high-temperature fusion bonding part of the hand mold can be heated by ultrasonic heating or heating wire.

[0046] Gloves can be 5 fingers or two fingers (big hands are stuffy), and the hand mold is the corresponding shape, dependin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com