Aluminum-foil paper automatic conversion device and conversion method thereof

An automatic conversion, aluminum foil paper technology, applied in the direction of packaging automatic control, packaging material feeding device, packaging, etc., can solve the problems of inconvenient operation, inconvenience to fix the winding roller, inconvenient to replace, etc., to achieve the effect of easy disassembly and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

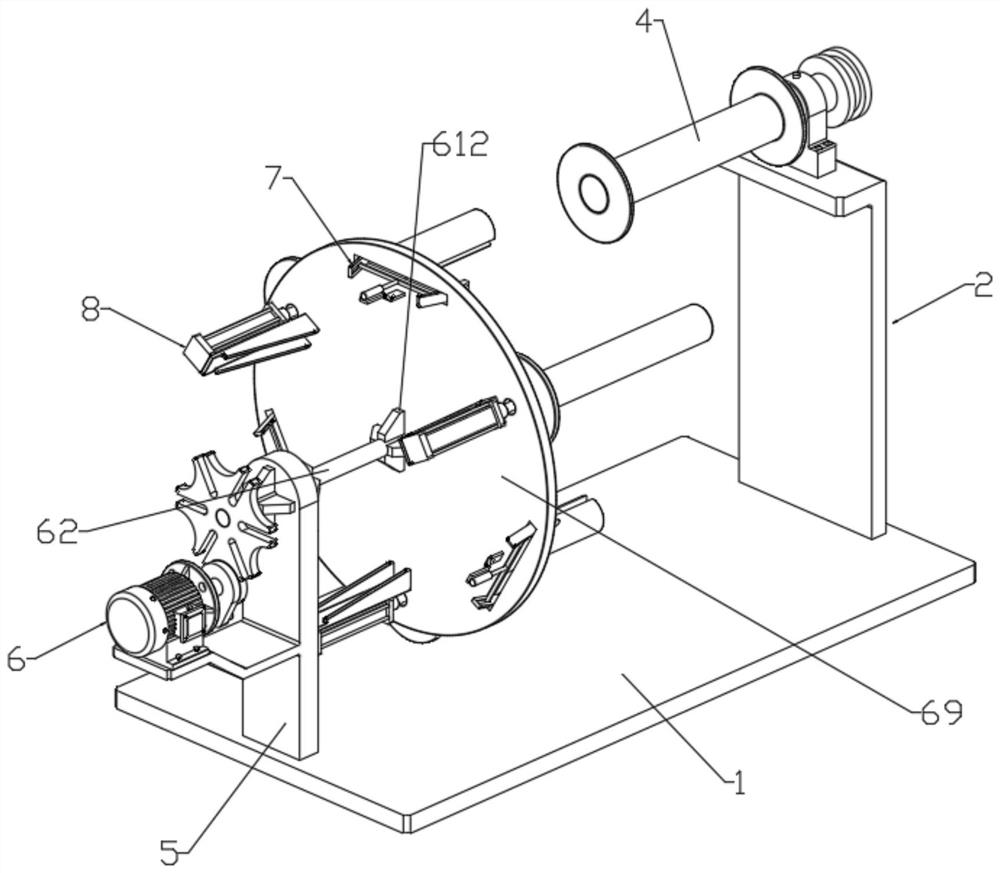

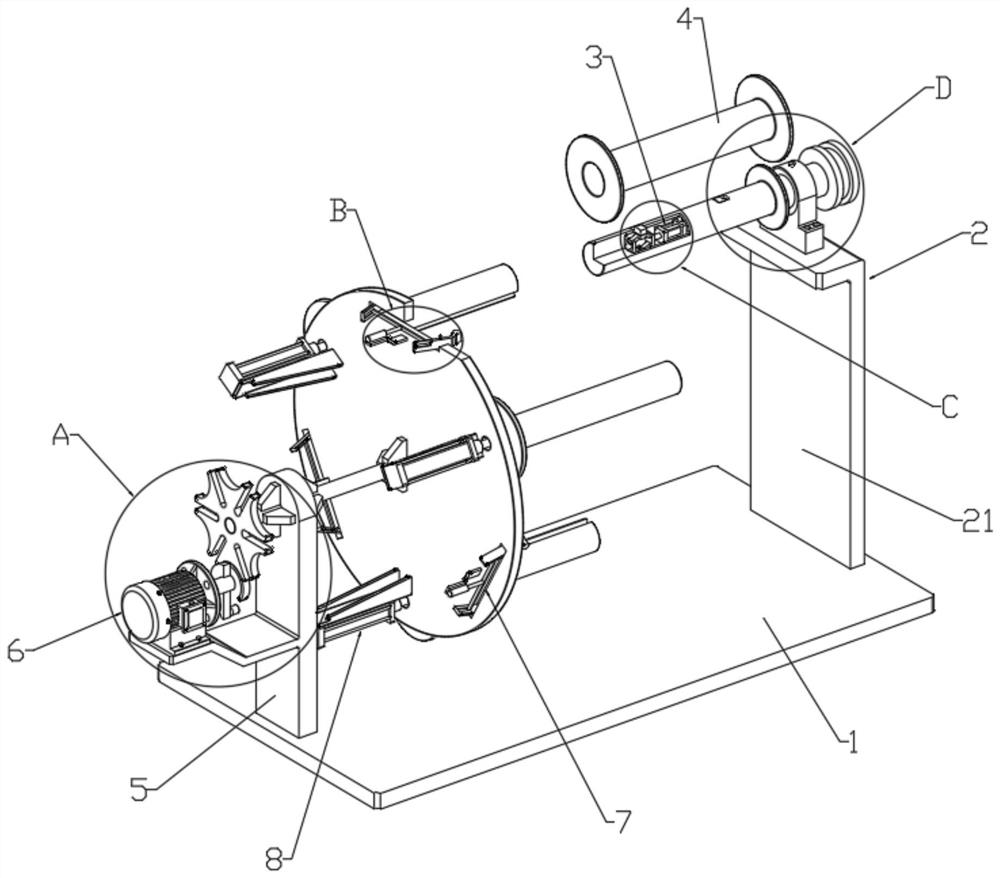

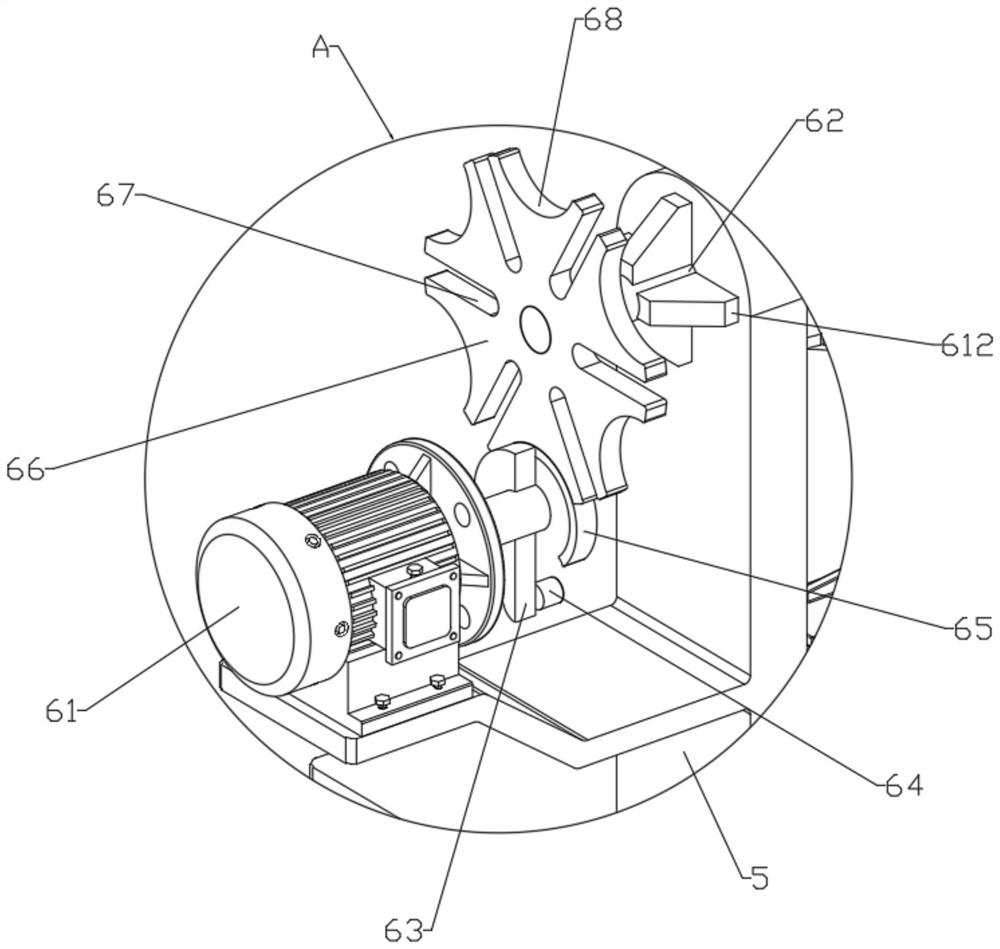

[0032] Example: Figure 1-8As shown, the present invention provides an aluminum foil paper automatic conversion device and a conversion method thereof, including a bottom plate 1, and a feeding mechanism 2 is provided on one side of the bottom plate 1, and a fixing mechanism 3 is provided inside the feeding mechanism 2. Moreover, the feed mechanism 2 is detachably provided with a winding roller 4, and the bottom plate 1 is slidably mounted on one side of the feed mechanism 2, and the bottom plate 1 is provided with a conveying mechanism and conveying mechanism that cooperate with the standby plate 5. The electrical steel body is controlled by the electric steel body, thereby ensuring the normal movement of the stand 5, and the stand plate 5 is provided with a batch rotating mechanism 6, and the intermittable rotation mechanism 6 is provided with an array distribution of a blade distribution. 7 With the upper body 8, and the sheet mechanism 7 is interleaved with the upper mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com