Finished product winding device for nanocrystalline film adhesive tape production

A winding device and nanocrystal technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of inconvenient production, inability to control the length of each roll of tape, etc., and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

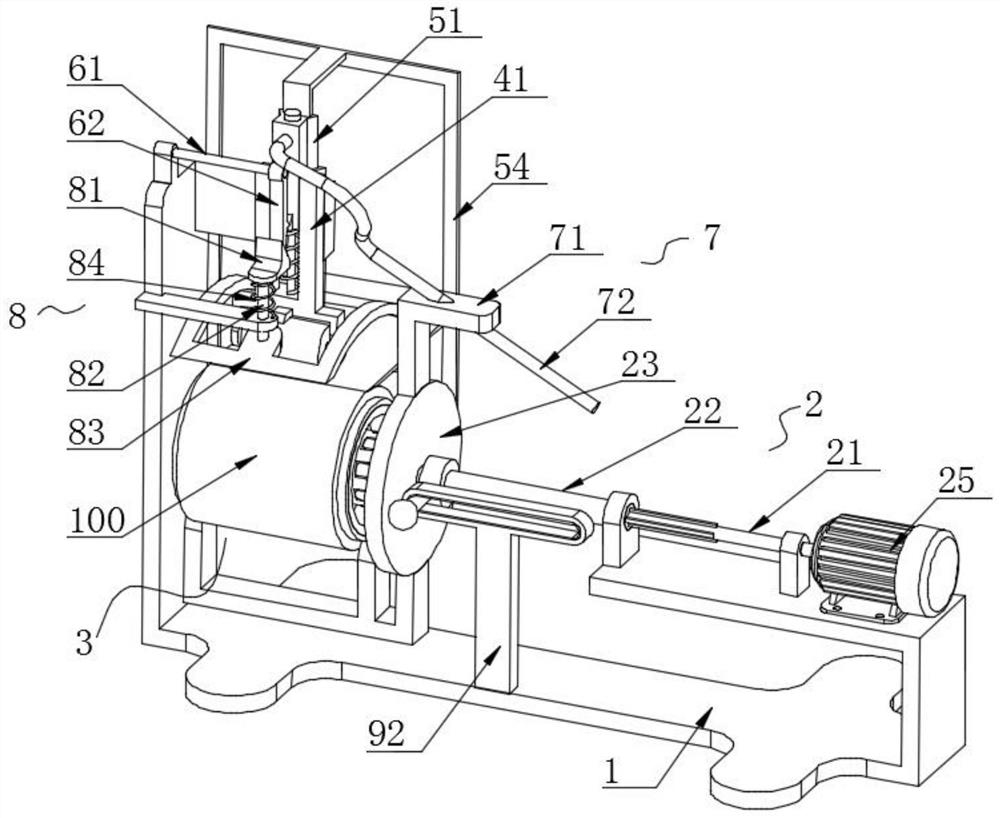

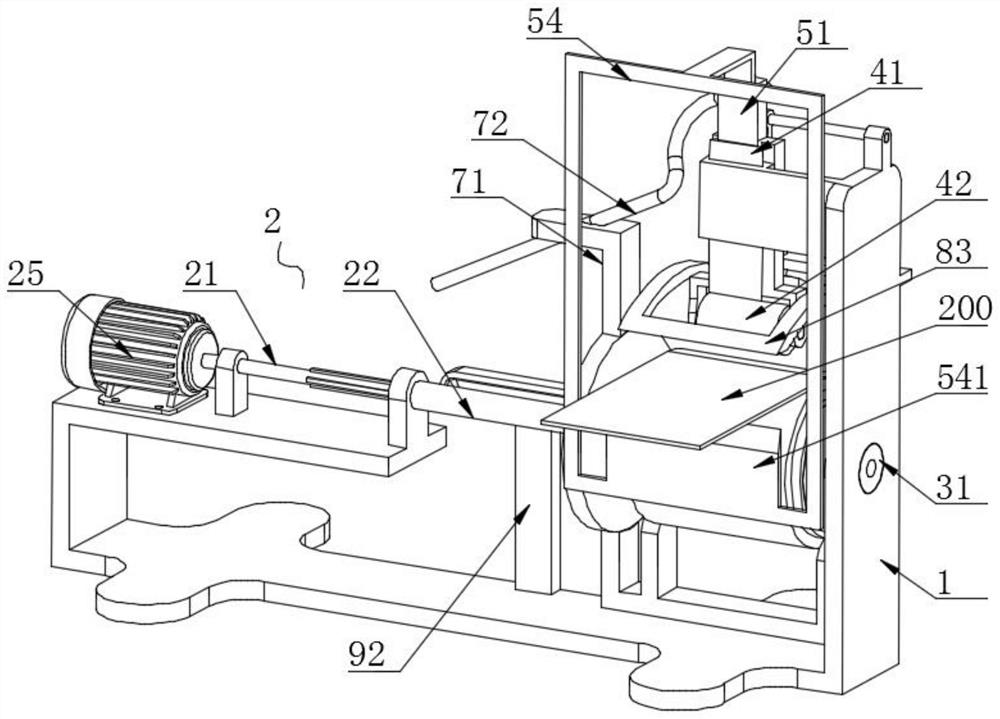

[0037] Such as Figure 1-10 As shown, it includes a frame 1, a driving assembly 2 and a winding assembly 3 are arranged above the frame 1, the driving assembly 2 can be combined with the winding assembly 3 to drive the winding assembly 3 to rotate, and it also includes a The lifting assembly 4 and the quick-lifting assembly 5 slidably arranged on the inner side of the lifting assembly 4 and the pushing assembly 7 arranged on one side of the lifting assembly 4, the lifting assembly 4 rises to drive the quick-lifting assembly 5 to rise, and the quick-lifting assembly 5 also includes Cutting off the cutter 541 of the adhesive tape, the quick-lifting assembly 5 can push the driving assembly 2 through the pushing assembly 7 to disengage the driving assembly 2 from the winding assembly 3 .

[0038] The drive assembly 2 includes a main shaft 21 that is rotatably connected to the frame 1. One end of the main shaft 21 is provided with a rotating shaft 22 through an internal and externa...

Embodiment 2

[0059] When the adhesive tape is cut off, the end of the adhesive tape may not be stuck on the good adhesive plaster 200 that has been rolled up, so as Figure 1-2 ,and Figure 5-7 As shown, on the basis of Embodiment 1, a pressing assembly 8 is provided on one side of the push rod 62. The pressing assembly 8 includes a push block 81, and the upper end of the push block 81 is provided with a pushing slope that contacts the bottom of the push rod 62. 811, the bottom of the push block 81 is fixedly connected with a connecting rod 82, and the bottom of the connecting rod 82 is fixedly connected with an arc-shaped plate 83 directly above the reel 31, and the outer side of the connecting rod 82 is provided with a spring two 84, and a spring two 84 The upper and lower ends of the upper and lower ends are pressed together with the push block 81 and the frame 1 respectively.

[0060] When the inner sliding plate 51 moves upward rapidly in the first embodiment (2), the push rod 62 swi...

Embodiment 3

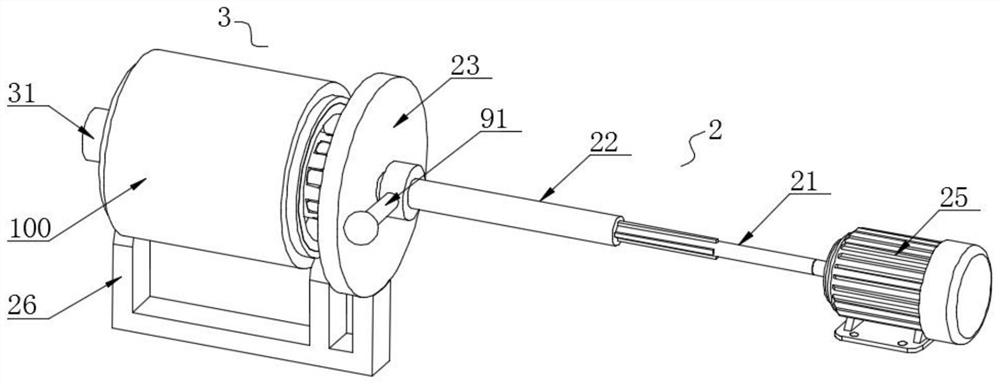

[0062] On the basis of Embodiment 1 or Embodiment 2, a push assembly 9 is provided. The push assembly 9 includes a driving lever 91 that is rotatably connected to the end of the rotating shaft 22 close to the sleeve 1 24. The push assembly 9 also includes a connection with the frame 1. The vertical plate 92 is fixedly connected, and the driving rod 91 is movably connected to the upper end of the vertical plate 92 and can slide inside. The inner side wall of the vertical plate 92 is fixedly connected with a friction plate 93, and the friction plate 93 is attached to the outer wall of the driving rod 91 .

[0063] In this way, in (3) of Embodiment 1, the rotating shaft 22 can be driven to move to the left by turning the lever 91, and the operation is more convenient. In addition, by setting the friction plate 93, the rotating shaft 22 and The driving lever 91 will not move to the right due to situations such as vibrations and cause the first 24 of the engaging sleeve and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com