Workshop intelligent transfer device

A transfer device and intelligent technology, applied in the direction of lifting devices, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as rack dumping, safety accidents, separation, etc., to increase the sealing effect, ensure production safety, and reduce the possibility of sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art may better understand the present invention, further described below aspect of the invention in conjunction with the accompanying drawings and embodiments.

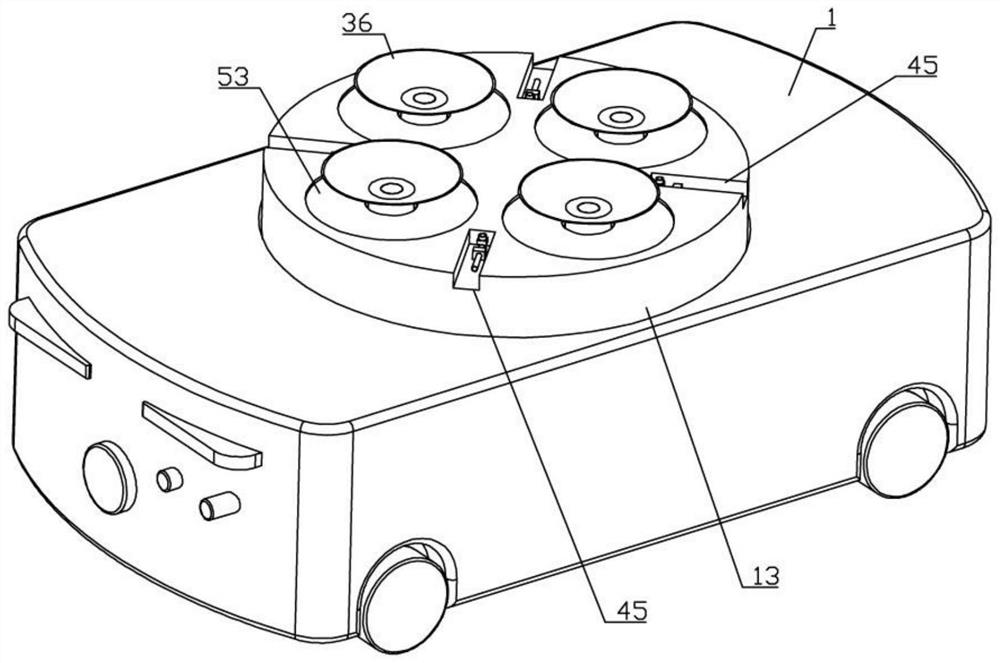

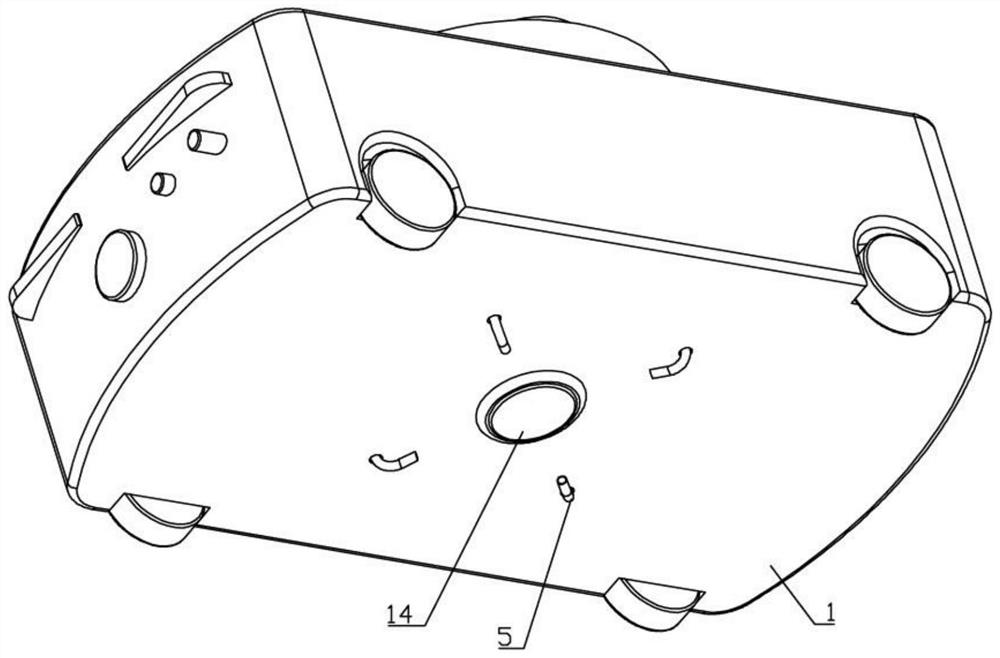

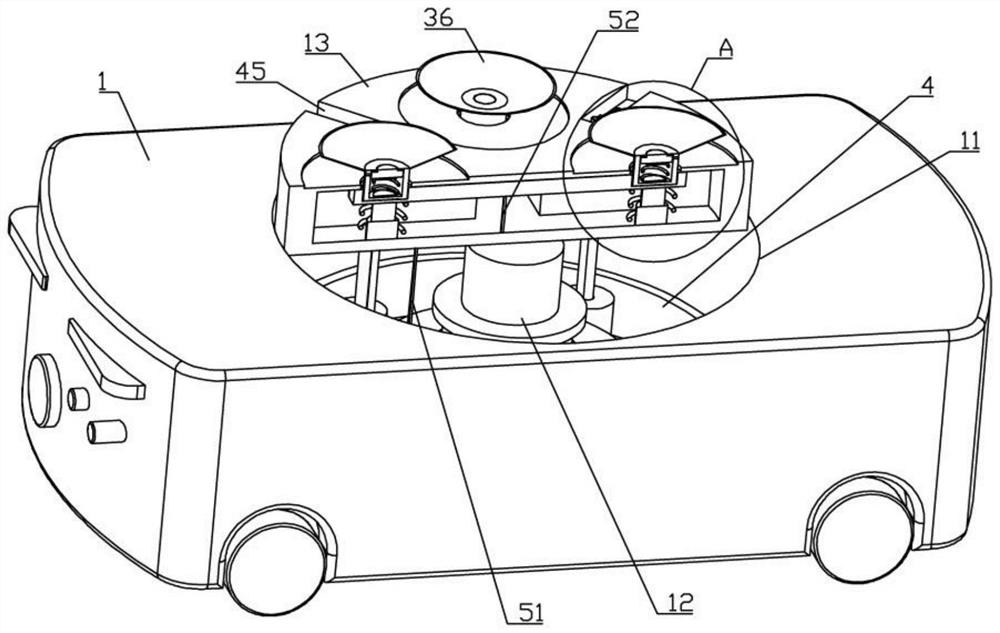

[0030] Such as Figure 1-9 As shown in a workshop intelligent transport apparatus of the present invention, includes a vehicle body 1, the body 1 is provided with upper mounting groove 11, the bottom of the mounting groove 11 is provided with a hydraulic cylinder 12, the output shaft 12 of the hydraulic cylinder 12 is fixedly connected Covered from the board 13, the bottom of the body 1 is provided with recognition camera 14, the inner top panel 13 is provided from the cavity 2, the cavity 2 is equipped with four telescopic rods 21, 21 are four sets of the telescopic rod 22 is provided with a first spring four telescopic rods 21 fixed to an upper end connected to a common support frame 23, the upper mounting bracket 23 with four mounting sleeve 24, the sleeve 24 is mounted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com