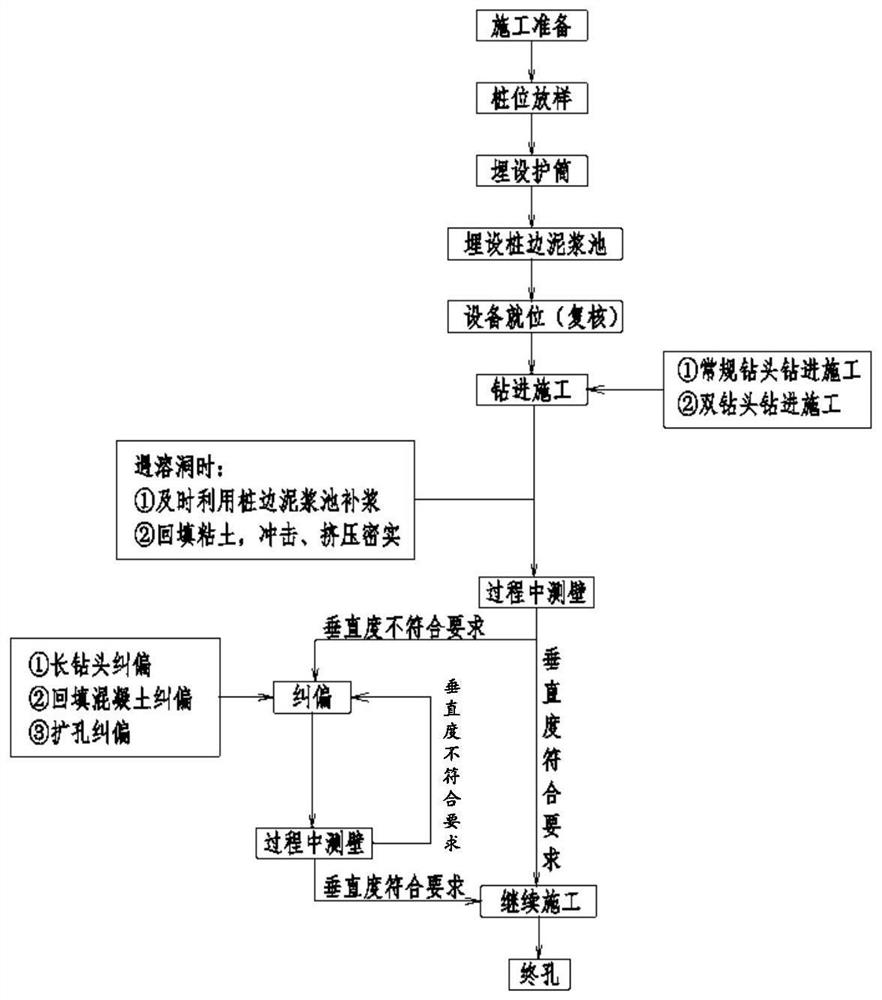

Cast-in-place pile hole-forming construction process in strong karst development area

A construction technique and cast-in-situ pile technology, which is applied in the direction of sheet pile walls, foundation structure engineering, drilling equipment and methods, etc., can solve problems such as easy deflection of karst caves and restrict construction period, and achieve the goal of saving concrete costs and improving construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

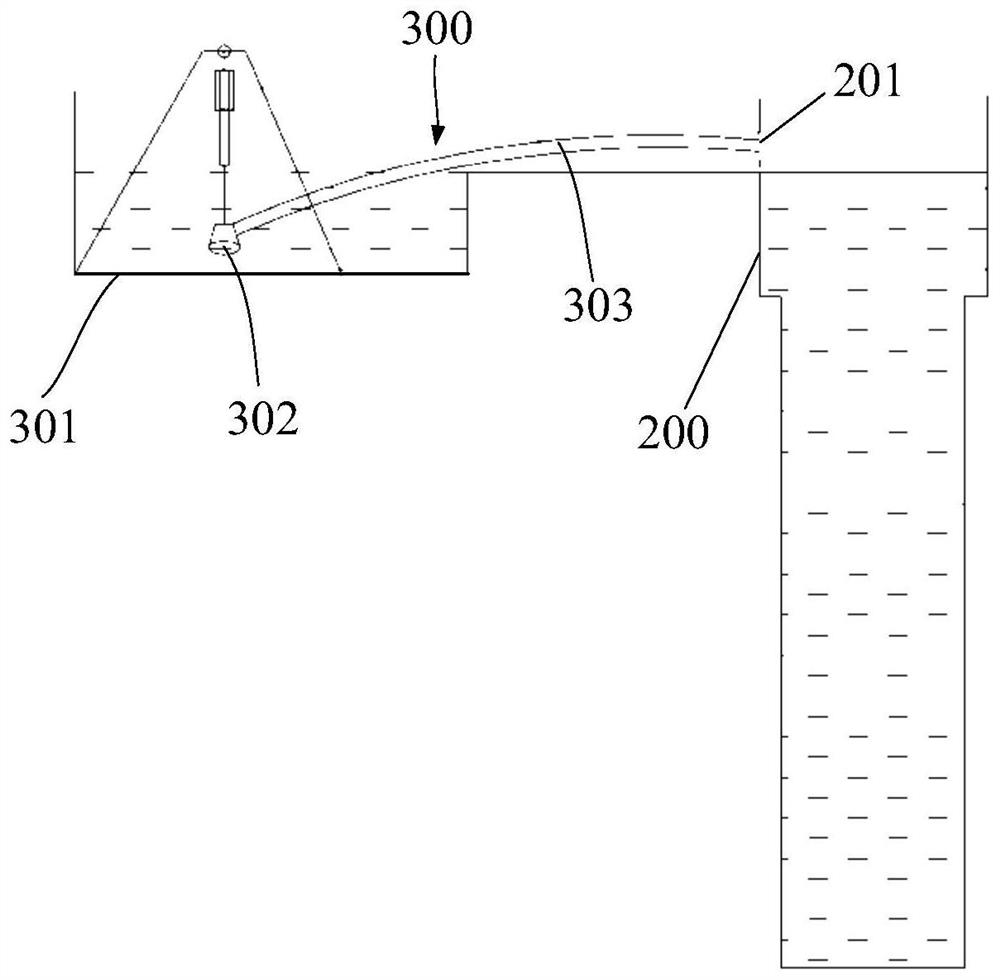

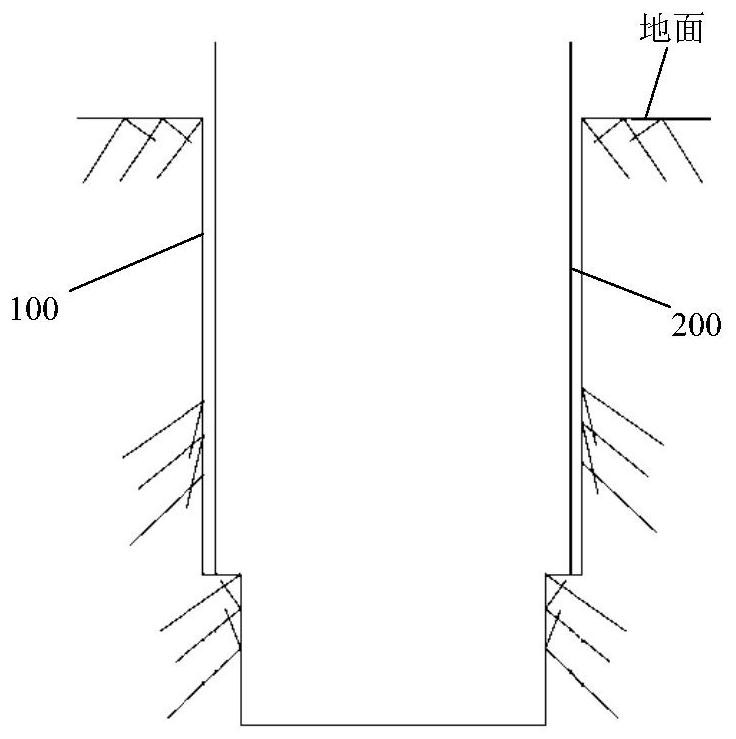

[0026] The present invention will be further described in detail below with reference to the accompanying drawings. The similar elements in different embodiments use the associated similar element reference. In the following embodiments, many detail descriptions are for better understanding of this application. However, those skilled in the art can recognize that some features may be omitted in different cases, or may be replaced by other elements, materials, and methods. In some cases, some operations related to this application are not shown or described in the specification, which is to avoid excessive descriptions of the core part of the present application, and those skilled in the art, detailed description The relevant operation is not necessary, and they can completely understand the relevant operations in accordance with the description in the specification and the general technical knowledge in the art.

[0027] In addition, the characteristics, operations, or features de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com