Method for accurately controlling normal-temperature sample tensile constant strain rate of universal testing machine

A universal testing machine and constant strain rate technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, instruments, measuring devices, etc., can solve problems such as difficult calculations, large numbers of physical quantities in iterative algorithms, and low control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention discloses a method for precisely controlling the tensile constant strain rate of a normal-temperature sample of a universal testing machine, and the idea is as follows:

[0026] Divide the sample tension into several loading cycles. Before each loading cycle, the physical quantities measured in the previous loading cycle need to be used to predetermine the loading termination conditions of this loading cycle (including load, sample measurement section displacement) and beam Displacement velocity, measure the loading force of the sample, the displacement of the sample in the measuring section, and calculate the strain rate. The parameters for the first loading cycle need to be set empirically.

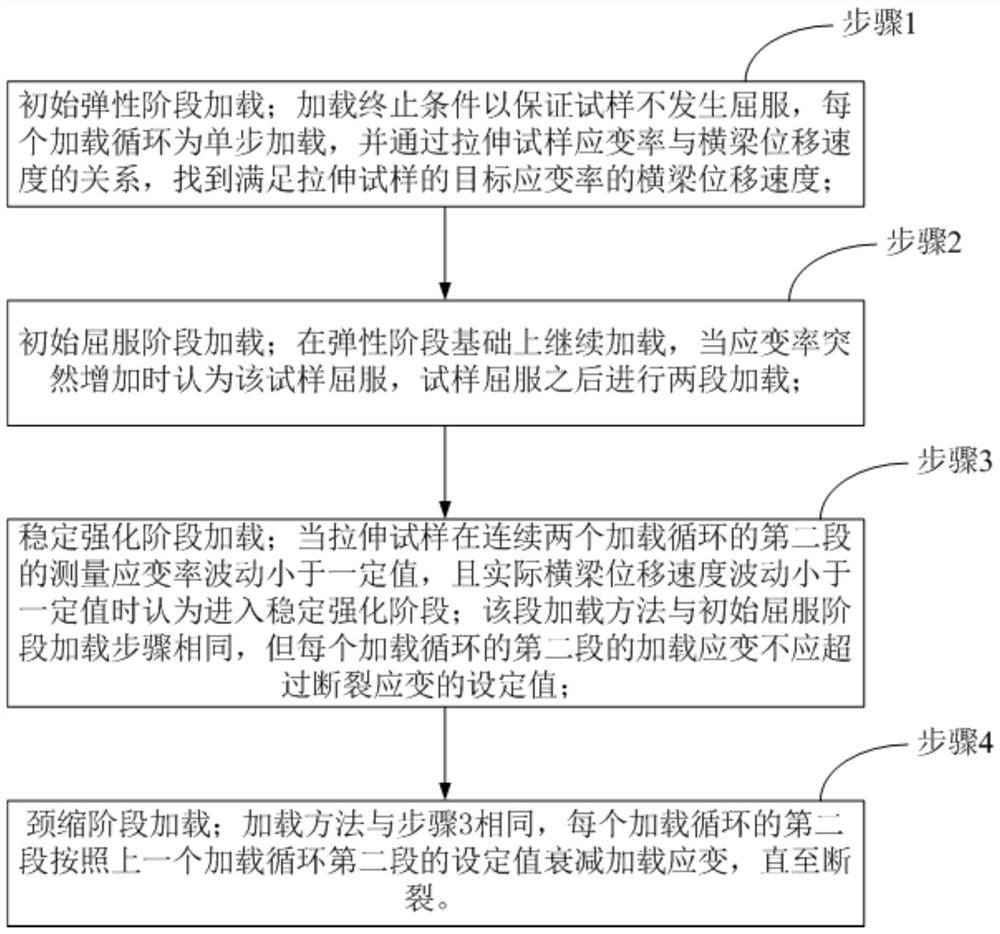

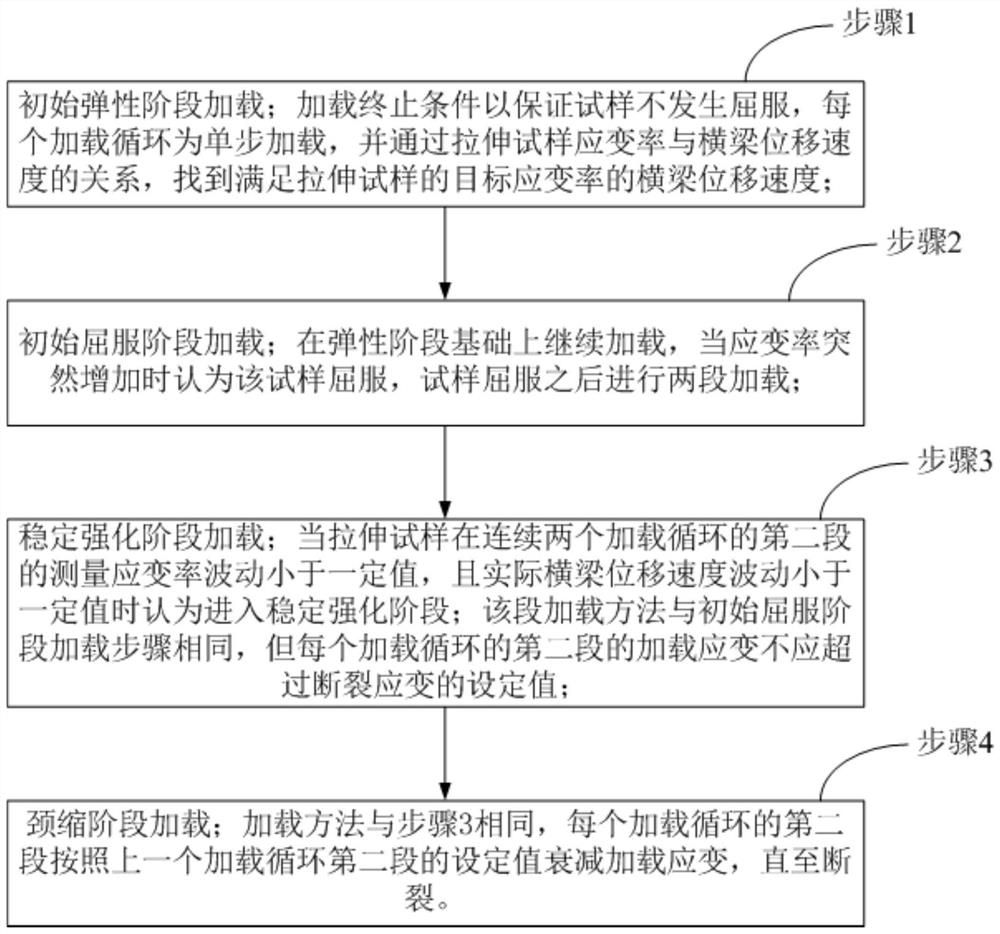

[0027] Such as figure 1 As shown, the present invention discloses a method for precise control of tensile constant strain rate of a normal temperature sample of a universal testing machine, comprising performing the following steps in sequence:

[0028] Step 1: Lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com