Low-temperature stretching rheometer and method for testing low-temperature performance of high molecular film

A polymer film, low-temperature performance technology, applied in the direction of flow characteristics, the use of stable tension / pressure test material strength, instruments, etc., can solve the problems that have not been reported before, near tens of degrees below zero, to achieve accurate Temperature control, adjustable cooling rate, and large torque range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

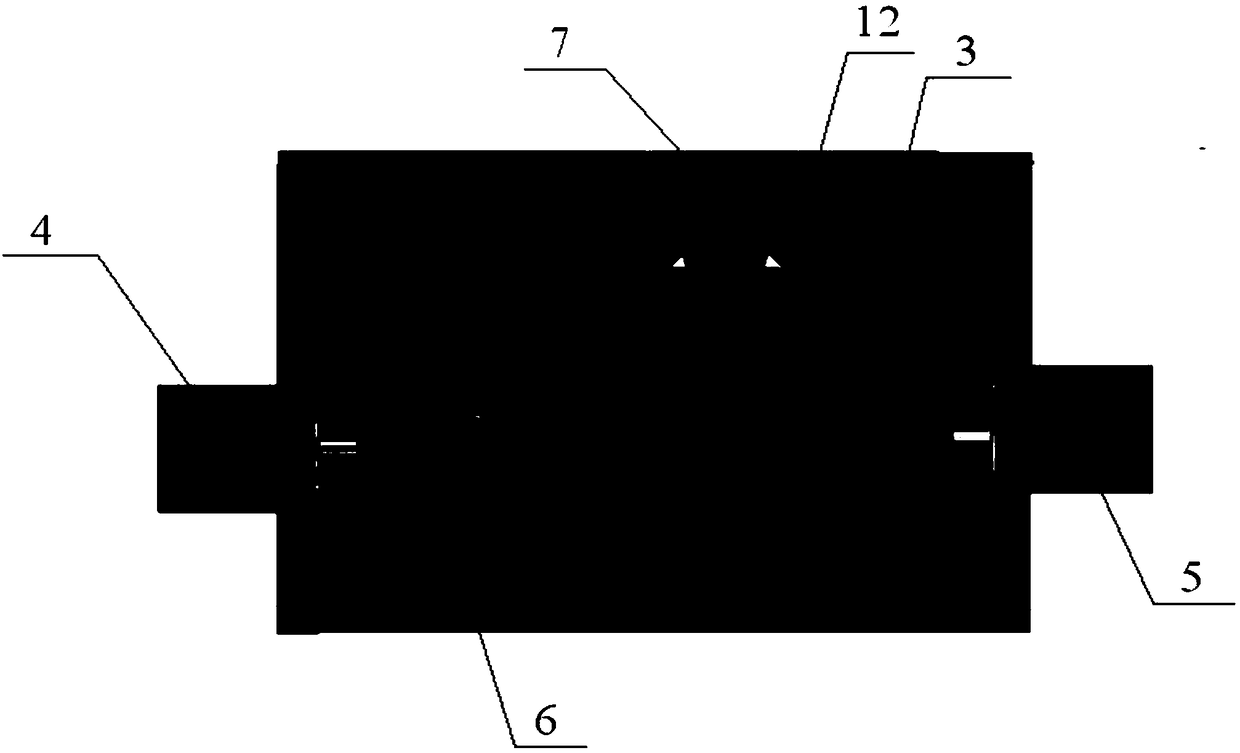

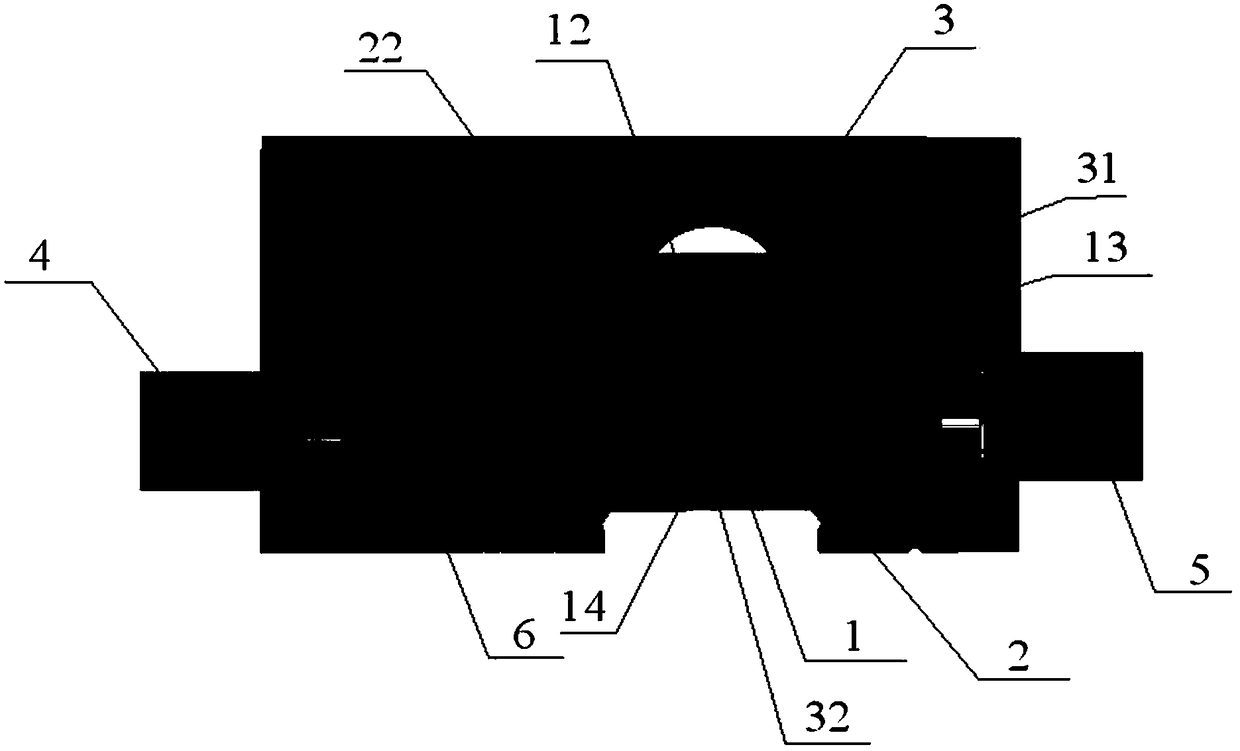

[0088] A low temperature extensional rheometer comprising:

[0089] The sample cavity is a double-roller fixture arranged in the sample cavity, and the double-roller fixture includes a first roller fixture and a second roller fixture, and both the first roller fixture and the second roller fixture have undergone sandblasting treatment;

[0090] A cooling chamber arranged outside the sample chamber, the cooling chamber communicates with a cold source; the cold source is a self-pressurized liquid nitrogen tank, and the self-pressurized liquid nitrogen tank communicates with the cooling medium inlet of the cooling chamber through a liquid nitrogen solenoid valve ;

[0091] A vacuum chamber arranged outside the cooling chamber, the vacuum chamber is connected with a miniature vacuum pump;

[0092] A first high-precision servo motor that is connected to the first roller clamp and drives the rotation of the first roller clamp;

[0093] A second high-precision servo motor that is c...

Embodiment 2

[0105] 2.1 Experimental example:

[0106] Synchrotron radiation X-ray in situ study of strain-induced crystallization of polymethylvinylsiloxane at ultralow temperatures.

[0107] 2.2 Purpose of the experiment:

[0108] Silicone rubber is a typical low-temperature elastomer, and the glass transition temperature of commonly used varieties is often below -100°C. Its performance at low temperatures is currently only at the stage of simple low-temperature mechanical properties research; X-rays are an important means of crystallographic research. One is an indispensable characterization method in the field of polymer material research. With the discovery and application of synchrotron radiation X-rays, the detection time resolution has been shortened from tens of hours in the past to the order of milliseconds; whether stretching at low temperature can induce its crystallization It has guiding significance for its low temperature performance.

[0109] 2.3 Experimental process:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com