Medium strain rate tensile experiment device

An experimental device and strain rate technology, applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult to maintain a stable strain rate, doubtful effect, difficult to accurately analyze and control the strain rate of the sample, and achieve accurate and stable control of strain The effect of smooth rate and strain rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

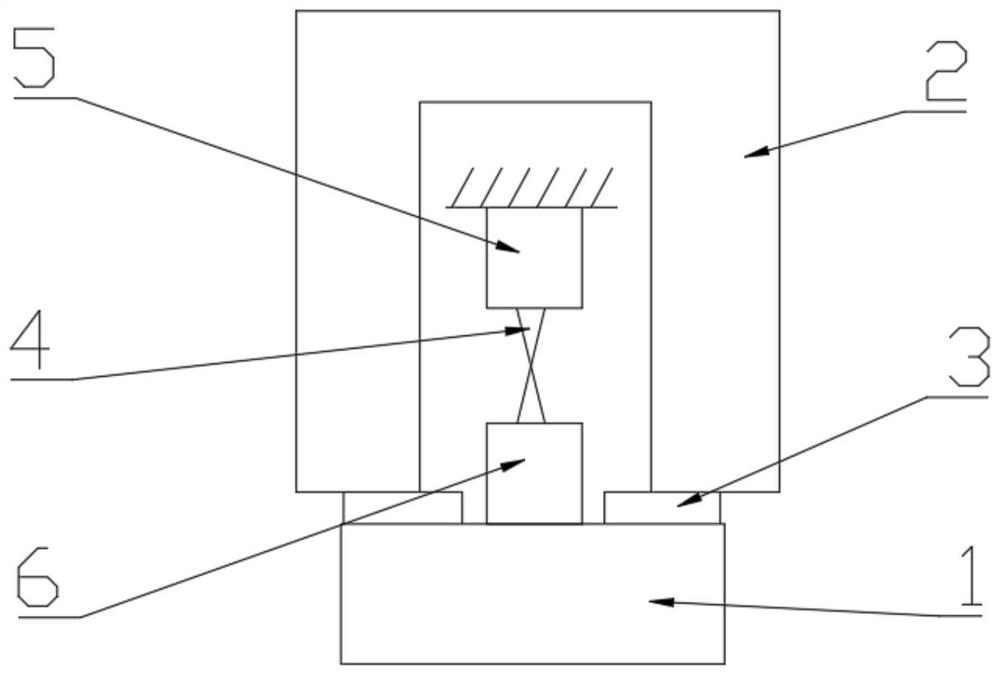

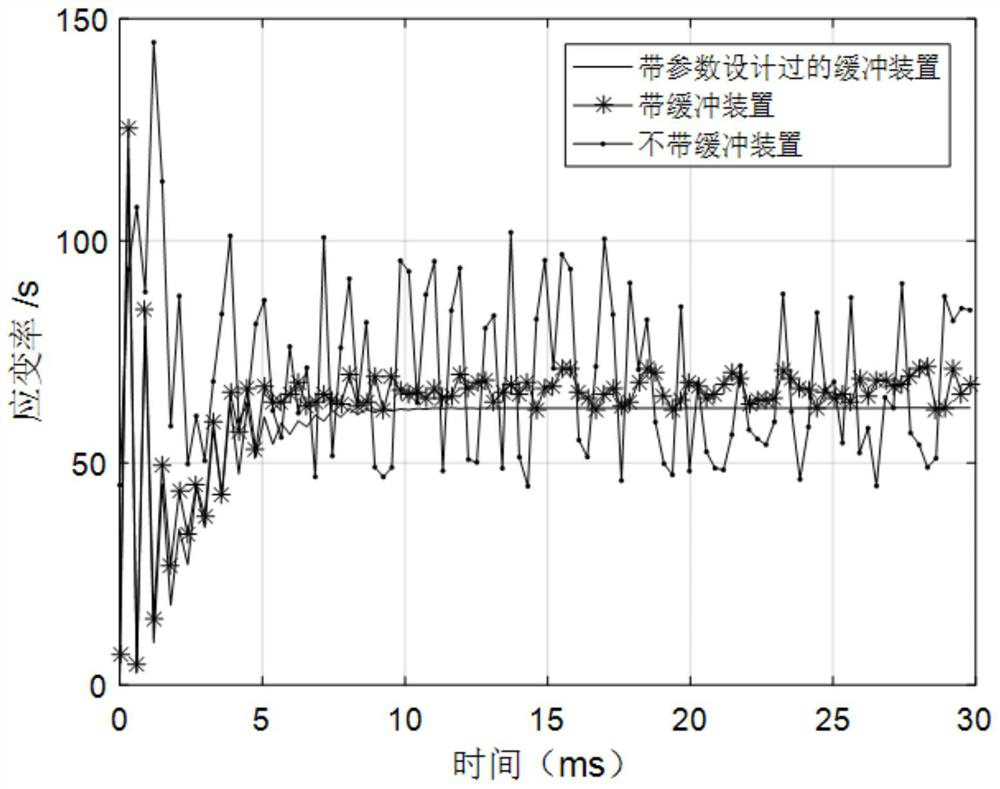

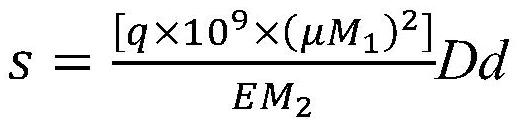

[0043] The upper clamp 5 is fixedly arranged on the tensile testing machine, and the sample 4 is arranged between the upper clamp 5 and the lower clamp 6; the base 1 is connected with the lower clamp 6, and the base 1 The drop hammer 2 is arranged above; the upper surface of the base 1 is provided with a buffer pad 3 corresponding to the drop hammer 2; the buffer pad 3 is an annular pad, and the drop hammer 2 is an annular drop hammer. The lower surface of the lower clamp 6 is fixedly connected, and the physical parameters of the buffer pad 3 are designed through the following formula:

[0044]

[0045] Wherein, s is the effective contact area between the drop weight 2 and the buffer pad 3, M 1 is the mass of drop hammer 2, E is the modulus of elasticity of buffer pad 3, M 2 is the quality of the base 1, D is the damping of the cushion 3, d is the thickness of the cushion 3, and q is a constant calibrated according to the experimental conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com