Anti-loose screw with double-thread nut

A double thread and nut technology, applied in the direction of nuts, threaded fasteners, screws, etc., can solve the problems of the nut anti-loosening interval becoming smaller, the reverse nut loosening, and the connector cannot be inserted into the connector, so as to reduce the number of accessories. , The effect of preventing the nut from loosening and reducing the accumulation of loose space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

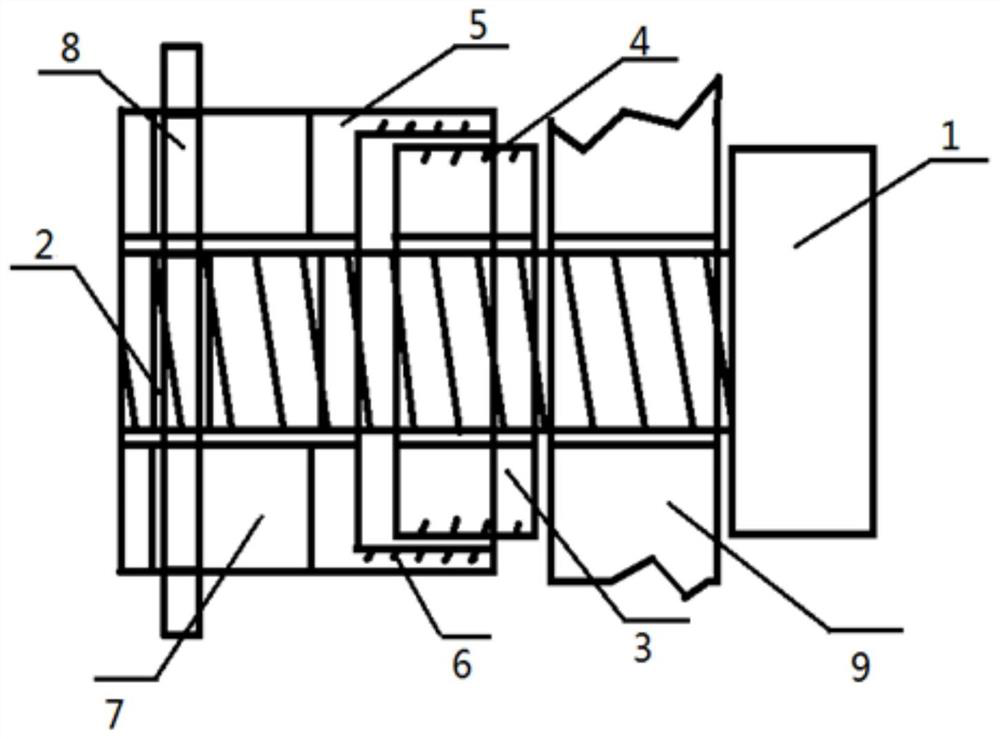

[0046] Such as Figure 1-12 As shown, a kind of anti-loosening screw adopting double-threaded nuts includes a screw rod 1, a nut 3 and a sleeve 5; one end of the sleeve 5 is threadedly connected with the nut 3; the screw rod 1 is screwed with the nut 3, and extends To the other end of the sleeve 5, this end is engaged with the screw rod 1 in a movable manner.

[0047] Way of working:

[0048] The screw goes through the fastened part 9 from one side of the fastened part 9, and is threaded with the nut 3. When the nut 3 is screwed into the screw 1 to reach the required position, the sleeve 5 is sleeved on the screw 1 and connected with the nut 3. screwed connection, and then the screw rod 1 is engaged with the sleeve 5 . The snap-fit connection prevents the sleeve 5 from rotating, and the sleeve 5 prevents the nut 3 from rotating, thereby achieving the purpose of preventing the screw from loosening.

[0049] When the fastener 9 vibrates, the fastener 9 transmits the vibrati...

Embodiment 2

[0052] Compared with Embodiment 1, the difference is that: a connection mode of the nut 3 and the sleeve 5 is provided.

[0053] Such as figure 1 As shown, the connection method is screw connection. The assembly and disassembly between the nut 3 and the sleeve 5 can be facilitated, and the sleeve 5 can be prevented from loosening along the axial direction.

Embodiment 3

[0055] Compared with Embodiment 1 or 2, the difference is that: a screw connection structure of the nut 3 and the sleeve 5 is provided.

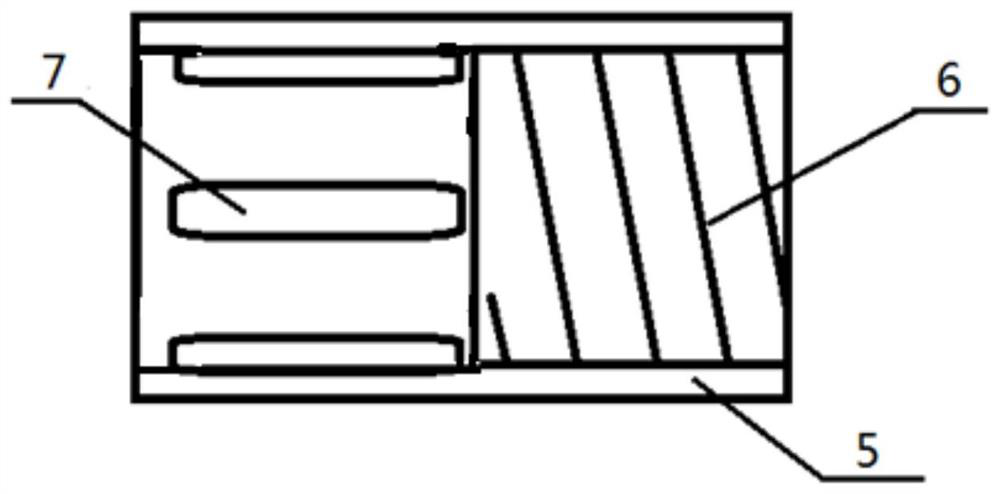

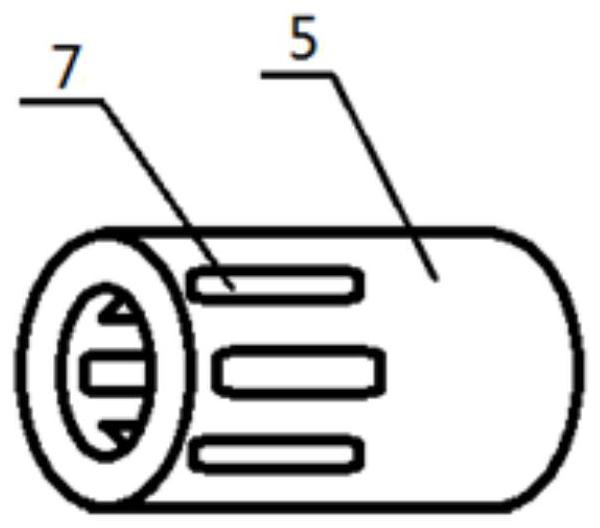

[0056] Such as figure 1 and 2 As shown, a first thread 4 and a second thread 6 are added; the first thread 4 is provided on the outer surface of the nut 3; the second thread 6 is provided on the inner surface of one end of the sleeve 5; wherein, the sleeve The barrel 5 and the nut 3 are screwed together with the first thread 4 through the second thread 6 .

[0057] Such as Figure 6 and 7 As shown, the outer side of the nut 3 is provided with a first thread 4, and its inner side is provided with an internal thread. Therefore, the nut 3 has double threads, which can apply two different rotational forces to the nut 3 from the inside and the outside at the same time, further improving the nut. anti-loosening effect.

[0058] The outer surface of the sleeve 5 and the thread 3 is threadedly connected; thus, the movable space of the sleeve 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com