Stabilizer bar assembly and vehicle

A stabilizer bar and assembly technology, which is applied in the field of auto parts, can solve the problems of increasing the number of parts and assembly processes, difficulty in ensuring sealing performance, and affecting the quality of sound pressure of the whole vehicle, so as to reduce the number of parts and improve the sealing performance , Eliminate the effect of abnormal sound failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

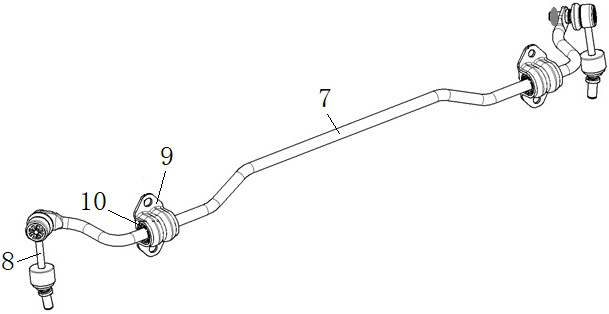

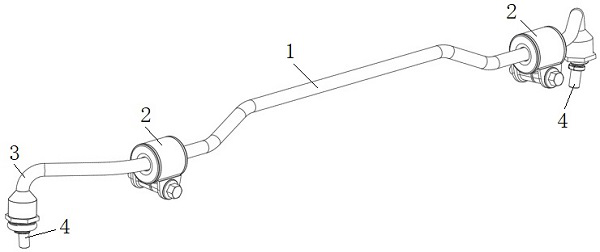

[0028] see figure 2 , the shown stabilizer bar assembly includes a rod body 1, the rod body 1 is connected to the vehicle body through a clamp assembly 2, the two ends of the rod body 1 are bent to form a connecting section 3, and the end of the connecting section 3 is provided with a ball stud One end of the assembly 4 is connected to the mounting hole 31 , and the other end of the ball stud assembly 4 is connected to the suspension system to transmit force and moment between the ground and the vehicle body. When one side of the wheel jumps up and down, the rod body 1 of the stabilizer bar assembly will rotate accordingly, and the stabilizer bar assembly is connected to the wheel on the other side to perform a corresponding jump, thereby reducing the inclination and shaking of the vehicle body.

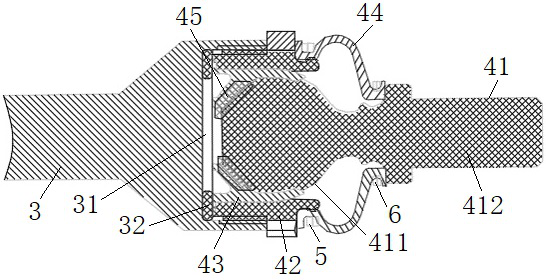

[0029] see image 3 , the ball stud assembly 4 includes a ball stud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com