Plastic tray for artware packaging

A technology for plastic pallets and packaging, applied in packaging, plastic containers, transportation and packaging, etc., can solve the problems of poor shock absorption and protection performance, and achieve the effects of poor shock absorption and protection performance, flexible and convenient use, and improved friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

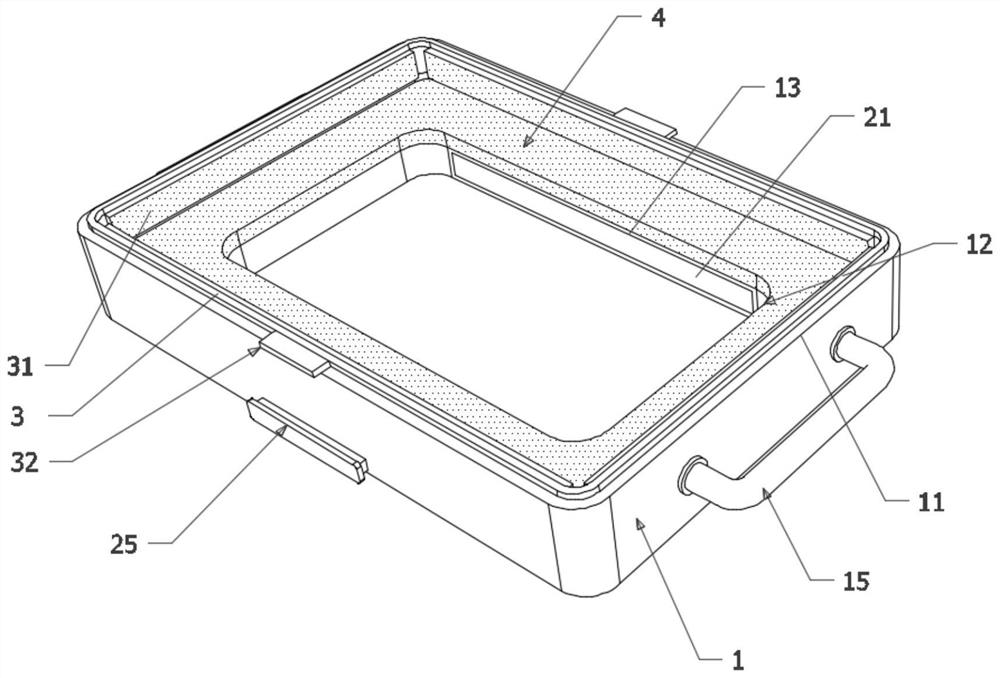

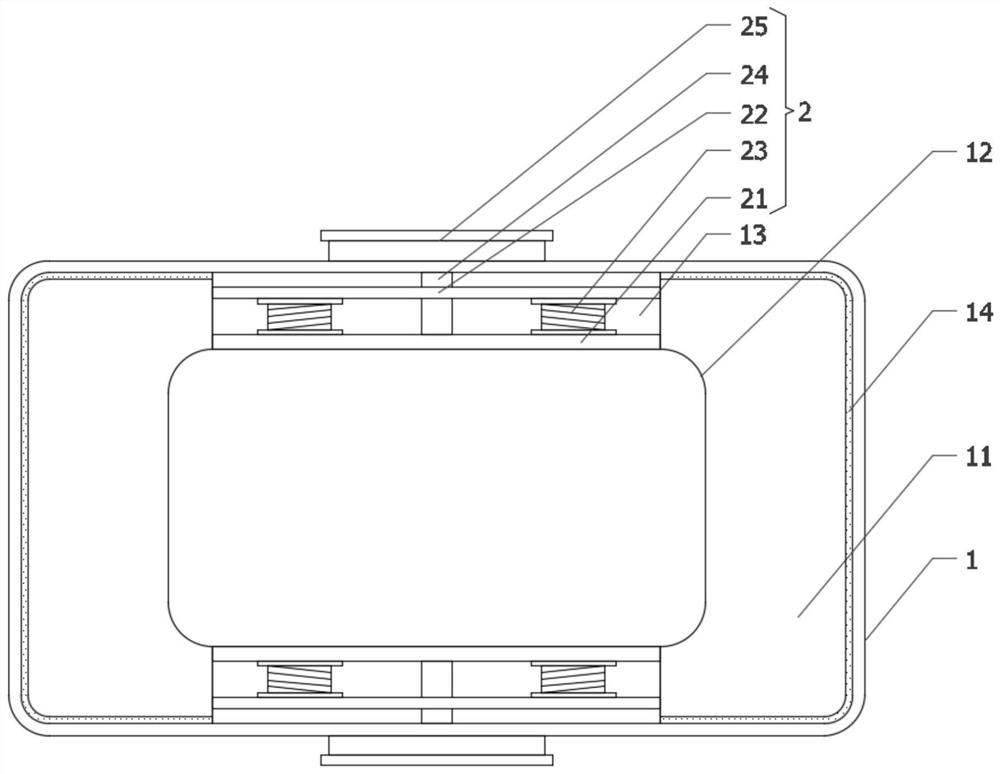

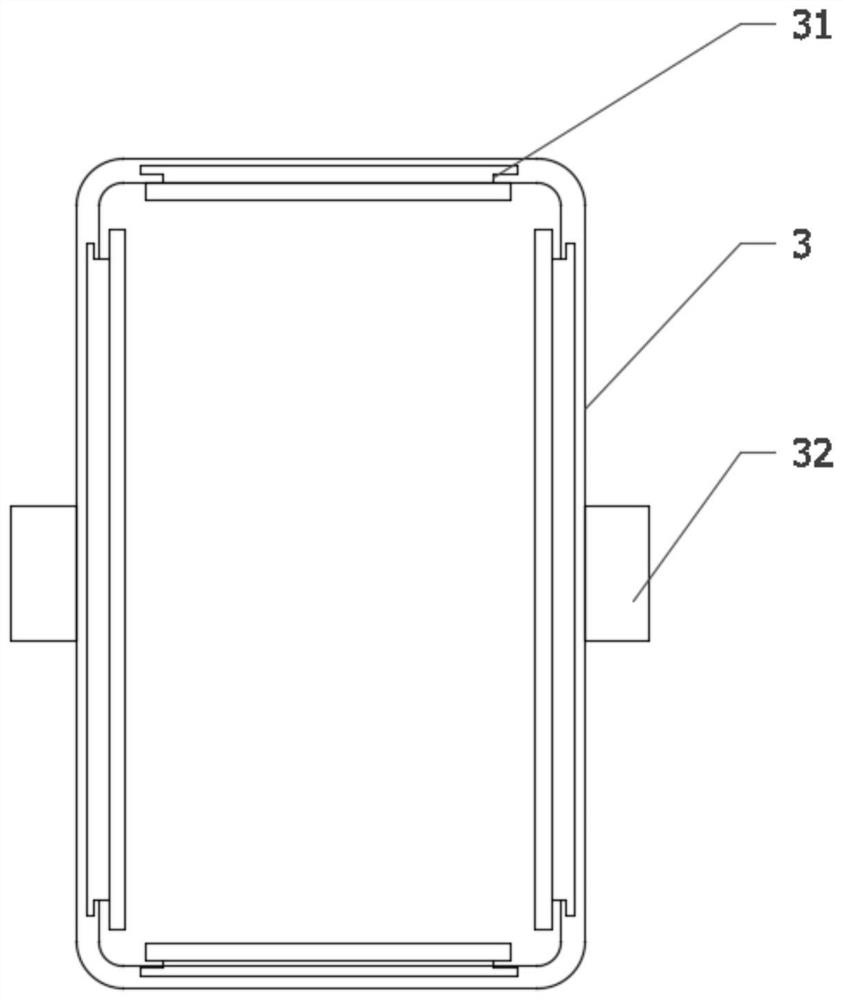

[0019] see Figure 1-Figure 3 , the present invention provides a plastic tray for handicraft packaging, comprising a chassis 1, two clamping mechanisms 2 are symmetrically installed in the chassis 1, both clamping mechanisms 2 include a clamping plate 21, two clamping The sides of the plates 21 away from each other are provided with a fixing plate 22, and two springs 23 are fixedly installed between the two clamping plates 21 and the corresponding fixing plates 22, and the two clamping plates 21 are fixedly connected with a pull rod 24 on the sides far away from each other. The ends of the two pull rods 24 that are far away from each other extend through the chassis 1, and a handle 25 is vertically fixedly installed. The top of the chassis 1 is detachably installed with an installation frame 3, and the inner frame wall of the installation frame 3 is embedded and fixed with a sponge strip. 31.

[0020] In particular, the top of the chassis 1 is provided with a first groove 11,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap