Shock pad for automobile

A shock-absorbing pad and automobile technology, applied in the field of auto parts, can solve the problems of a single shock-absorbing pad, poor shock absorption effect, and short service life, and achieve good shock absorption effect, enhanced elastic strength, and short service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

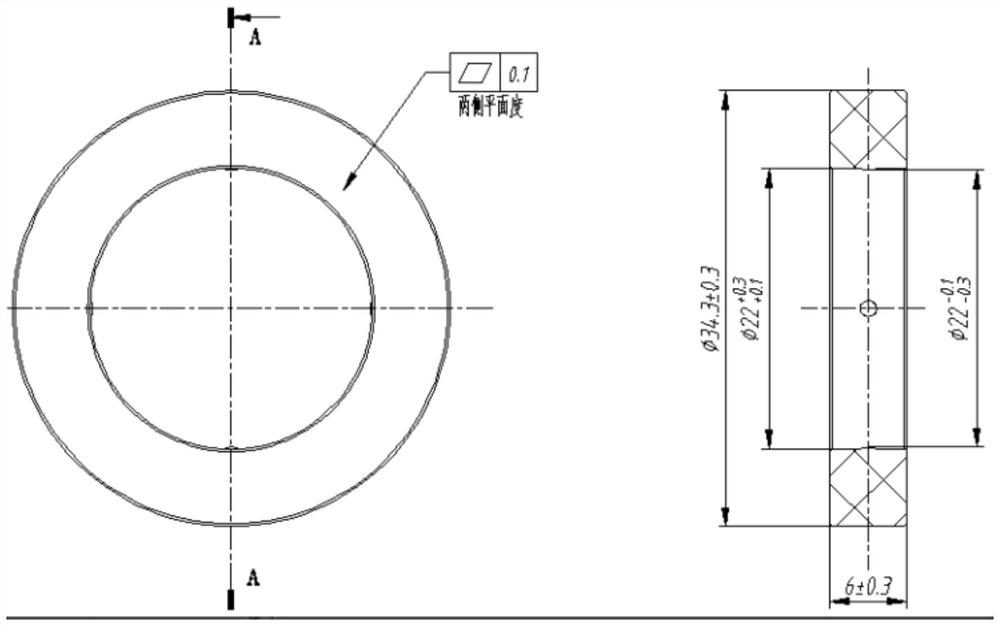

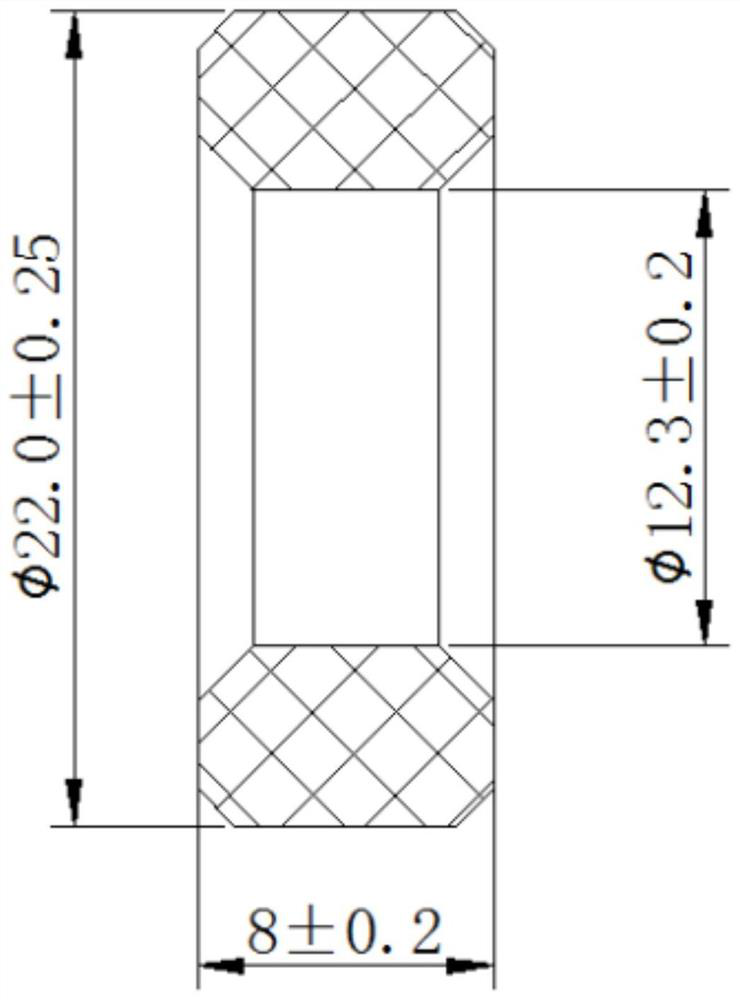

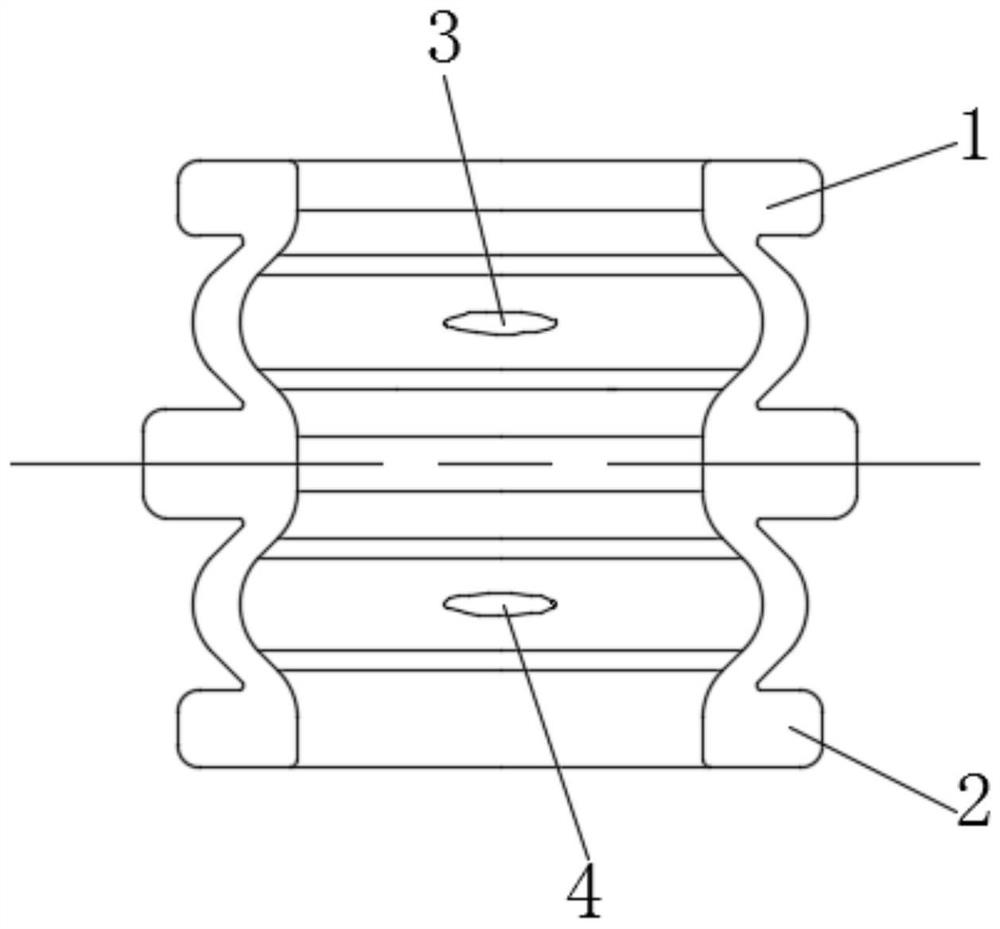

[0028] see image 3 - Figure 4 As shown, the present invention is a kind of shock absorber for automobiles, comprising shock absorbing mechanism one 1 and shock absorbing mechanism two 2, shock absorbing mechanism one 1 is positioned at the upper end of shock absorbing mechanism two 2, it is characterized in that shock absorbing mechanism one 1 It is a mirror image with the shock absorbing mechanism 2 2 , the inside and outside of the shock absorbing mechanism 2 2 are corrugated, and the shock absorbing mechanism 2 2 includes a connecting portion 21, a raised portion 22 and an end portion 23, and the raised portion 22 is located at the connecting portion 21 and the end portion 23 , the connection portion 21 is located above the end portion 23 , and the connection portion 21 , the protruding portion 22 and the inside of the end portion 23 are connected.

[0029] The integral one-piece injection molding of shock absorbing mechanism 1 and shock absorbing mechanism 2 2, the oute...

Embodiment 2

[0031] see Figure 5 As shown, the difference from the first embodiment is that: the outer surfaces of the protrusions 22 of the shock absorbing mechanism 1 and the shock absorbing mechanism 2 are provided with an annular connecting ring 5, and the through hole 3 and the through hole Two 4 all run through the connecting ring 5. Taking the shock absorbing mechanism 1 as an example, when under pressure, the shock absorbing mechanism 1 is first impacted and deformed, and the upper and lower ends of the protrusions 22 in the shock absorbing mechanism 1 are close to each other. , the whole has a tendency to expand outward, the cavity in the connecting ring 5 and the shock absorbing mechanism-1 provides sufficient deformation space, and the connecting ring 5 enhances the static stiffness, so as to avoid excessive extrusion and rupture of the raised part 22, which cannot return For the problem of spring, the connecting ring 5 provided can enhance the overall static stiffness of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com