Elastic coupler

An elastic coupling and half-coupling technology, applied in elastic couplings, couplings, mechanical equipment, etc., can solve the problems of weak torque bearing capacity, complex structure, lack of buffer, etc., to increase the torque bearing capacity and rigidity, compactness, improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

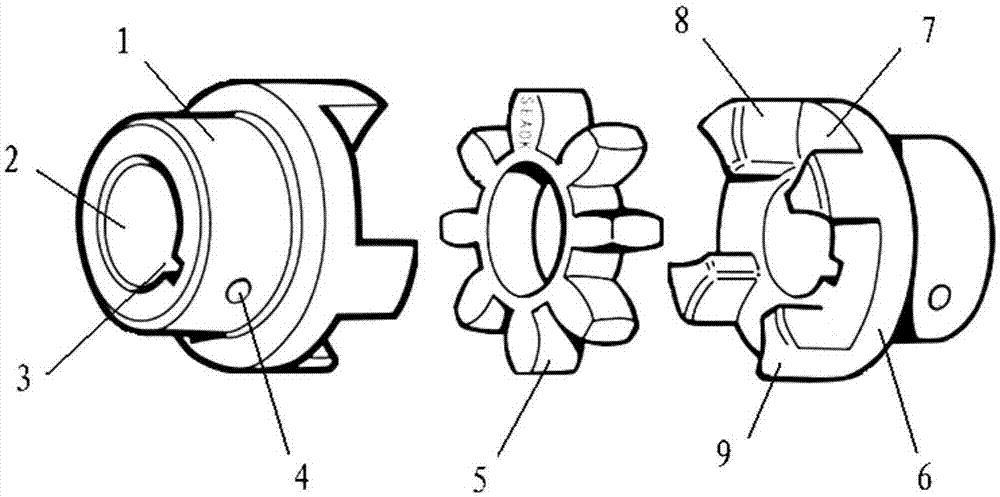

[0017] refer to figure 1 , the present invention provides an elastic coupling, including a first half coupling 1, a second half coupling 6 and a rubber pad 5; the first half coupling 1 and the second half coupling 6 have the same structure; The material of the first half coupling 1 is stainless steel; the first half coupling 1 is provided with a groove portion 7 and a raised portion 8; the groove portion 7 and the raised portion 8 are arranged at intervals; the first half coupling 1 A shaft hole 2 is provided; a keyway 3 is provided on the shaft hole 2; a rubber pad 5 is installed between the first half-coupling 1 and the second half-coupling 6, and fits the groove part 7;

[0018] The material of the first half coupling 1 is stainless steel.

[0019] The shaft surface of the first half coupling 1 is provided with a screw hole 4, and the screw hole 4 is intersected with the shaft hole 2; the center of the screw hole 4 coincides with the center of the keyway 3; the protrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com