Horizontal pushing type narrowing machine

A narrow-band, flat push technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problem that the number of car sections cannot be increased or decreased at will, and achieve the effect of increasing or decreasing the length and reducing the design pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

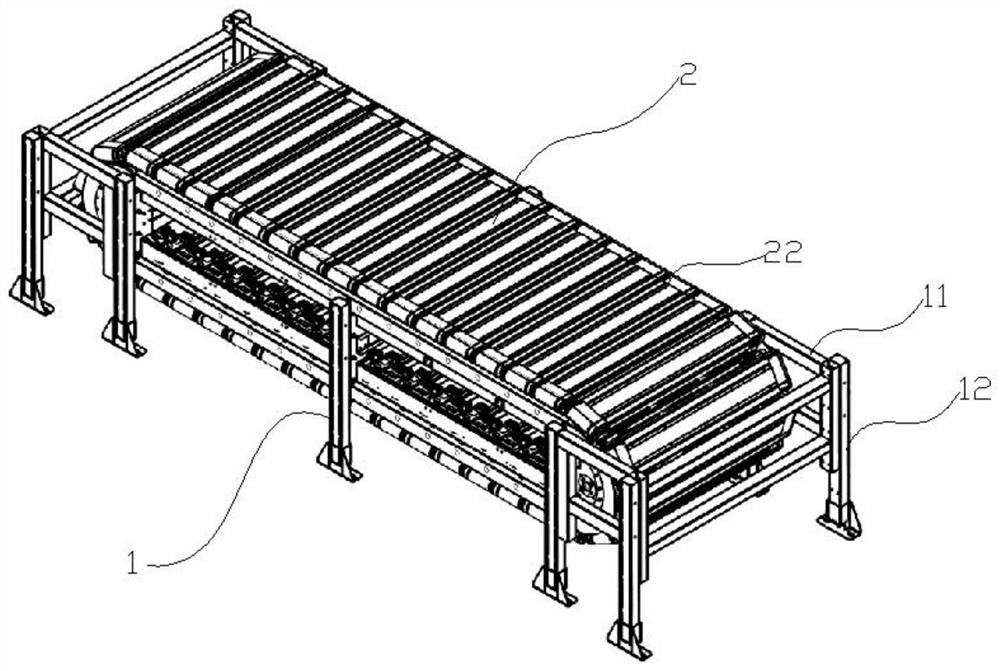

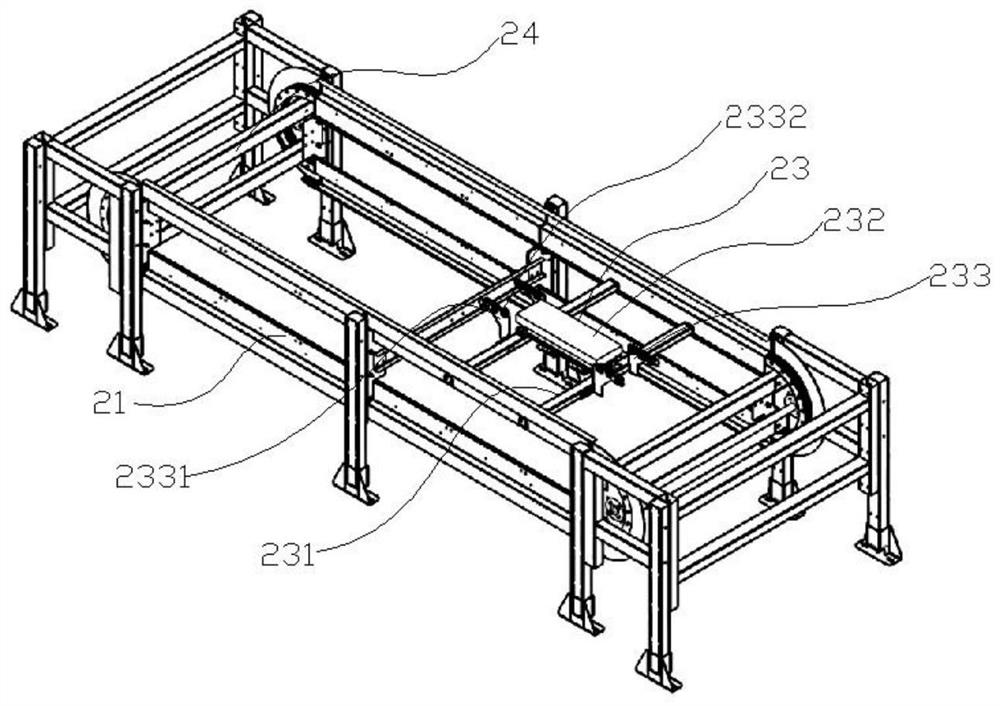

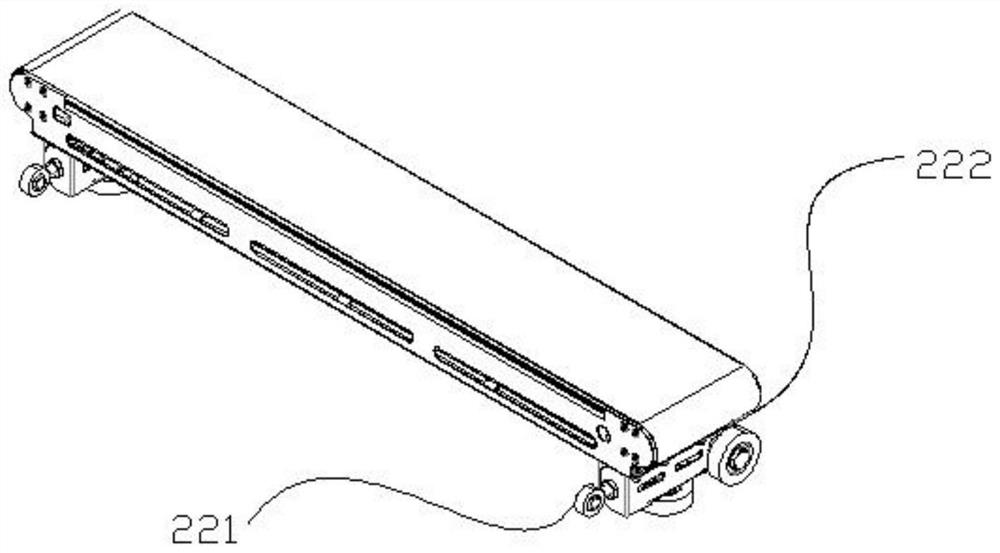

[0025] In order to solve the existing narrow-band machines in the prior art, once the production is completed, it is difficult to adjust the pitch and height, and occupy a large space. Figure 1-3 As shown, it includes a bracket 1 and a narrowband machine body 2 arranged on the bracket; the narrowband machine body 2 includes two circular tracks 21, two ends of which are arranged on the circular track 21 and can be connected to the circular track 21 Several trolleys that slide up, are used to drive the trolleys to slide on the circular track 21 and are arranged between the two circular rails 21. A flat push motor assembly 23, and several trolleys form a ring that matches the circular track 21. .

[0026] When the flat-push narrowband machine provided by Embodiment 1 of the present invention is working, the flat-push motor 232 will push the trolley 22 to slide on the circular track 21, so as to realize the movement of the trolley 22 on the circular track 21, thereby realizing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com