Paper direction changing device for digital printer

A technology for printers and paper is applied in the field of paper orientation changing devices for digital printers, which can solve the problems of low printing efficiency, increased labor intensity of staff, and inability to realize automatic paper reversal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

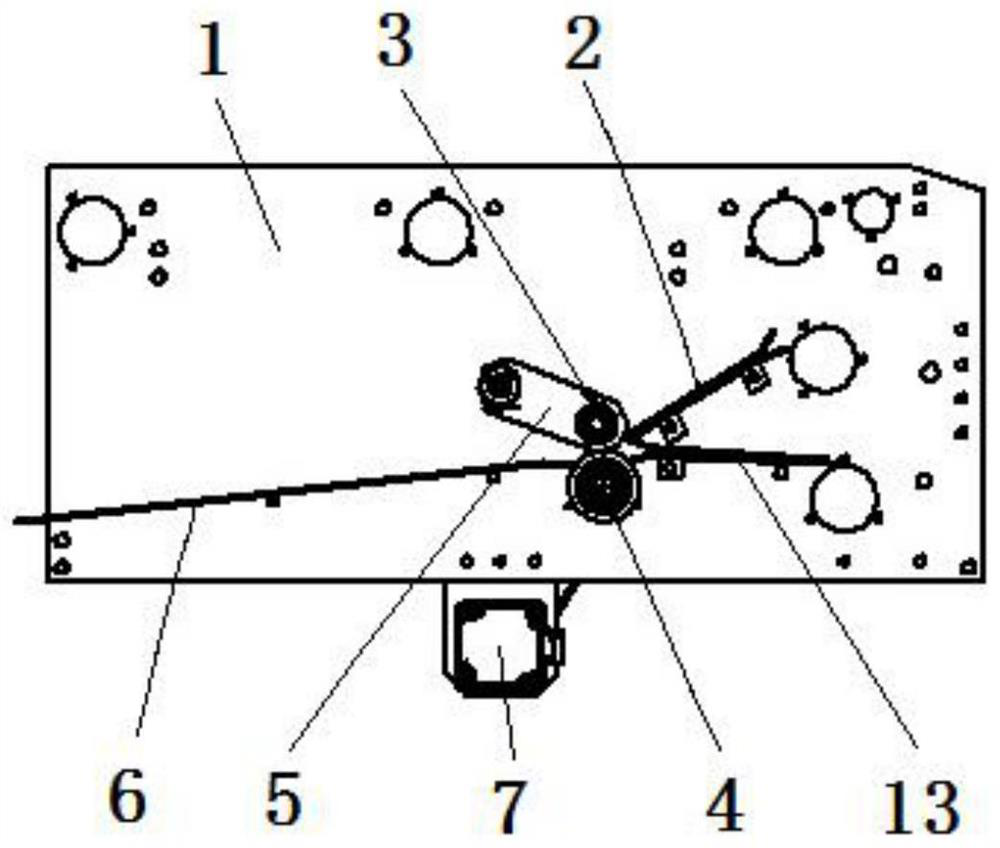

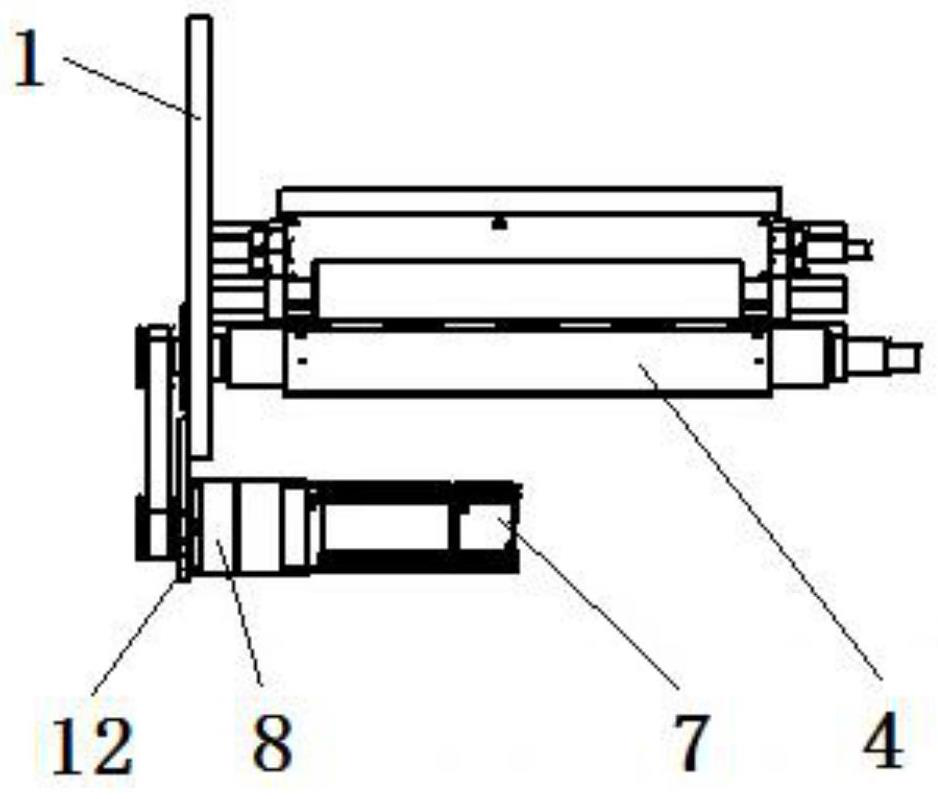

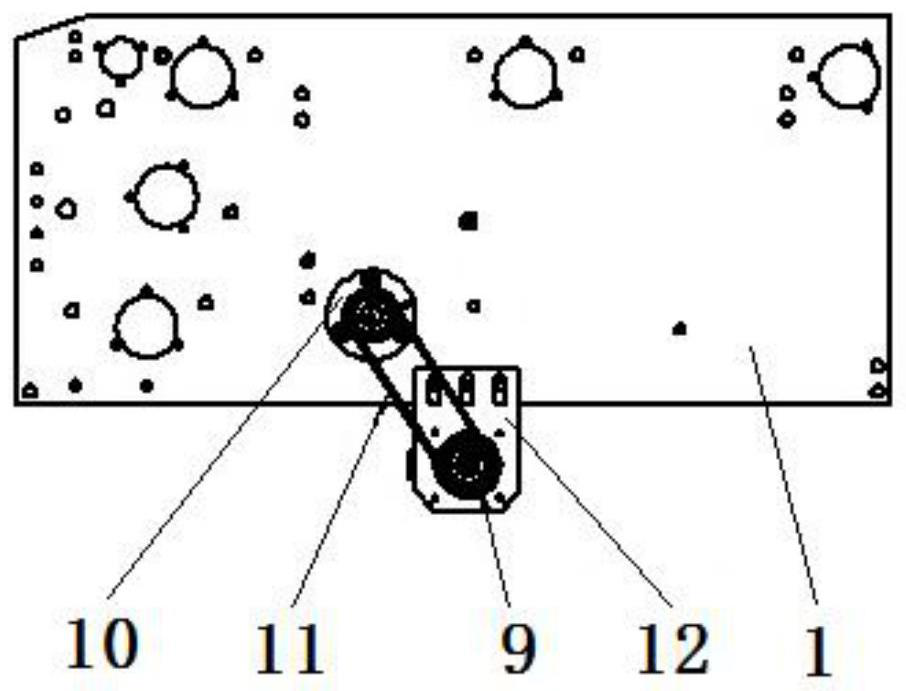

[0018] Such as Figure 1-4 As shown, a paper direction changing device for a digital printer includes a frame 1, a conveying channel 2 is arranged in the middle of the frame 1, the conveying channel 2 is arranged obliquely, and a conveying shaft is arranged at the bottom end of the conveying channel 2 4. The conveying shaft 4 is rotatably mounted on the frame 1, a driving assembly is arranged below the conveying shaft 4, and a platen shaft 3 is arranged above the conveying shaft 4, and the platen shaft 3 A pendulum 5 is provided on both sides, and the platen shaft 3 is rotatably mounted on the pendulum 5 through a bearing 16 , and the end of the pendulum 5 away from the paper platen 3 is rotatably connected by a fixed pin 14 On the frame 1, a passage for paper to pass is provided between the platen shaft 3 and the conveying shaft 4, a paper guide plate 6 is provided on the left side of the passage, and a paper guide plate 6 is provided on the right side of the conveying shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com