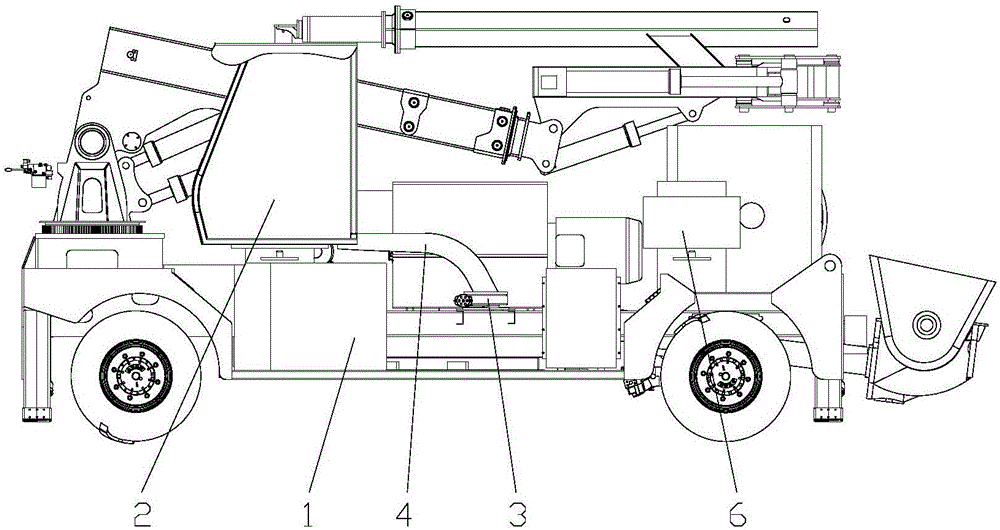

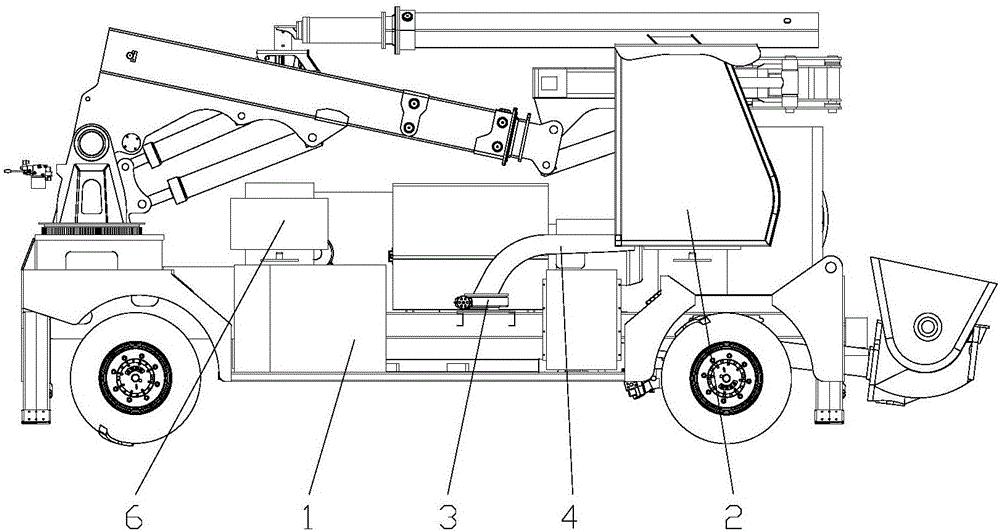

Turning-around device for concrete wet-spraying machine cockpit

A U-turn device and cockpit technology, used in shaft equipment, earth-moving, transportation and packaging, etc., can solve the problems of difficult U-turn, hidden safety hazards, obstructing the driver's sight, etc., and achieve the effect of wide driving vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: as Figure 4 As shown, the drive system 5 includes a worm gear 51, a worm screw 52 and a motor 53, the worm gear 51 is fixed on the lower end of the swing arm 4, the worm screw 52 is fixed on the output shaft of the motor 53, and the worm screw 52 meshes with the worm gear 51. The motor 53 drives the worm 52 to rotate, and the worm 52 drives the worm wheel 51 to rotate so as to drive the swing arm 4 to rotate.

Embodiment 2

[0023] Embodiment 2: as Figure 5 As shown, the drive system 5 includes a driving gear 51, a driven gear 52 and a motor (not shown), the driven gear 52 is fixed on the lower end of the swing arm 4, the driving gear 51 is fixed on the output shaft of the motor, and The driving gear 51 meshes with the driven gear 52 . The motor drives the driving gear 51 to rotate, and the driving gear 51 drives the driven gear 52 to rotate so as to drive the swing arm 4 to rotate.

Embodiment 3

[0024] Embodiment 3: as Figure 6 or Figure 7 As shown, the driving system 5 includes a slewing bearing 51, a rack 52 and a drive cylinder 53, the inner ring of the slewing bearing 51 is fixed on the vehicle frame 1, the lower end of the swing arm 4 is fixedly connected with the outer ring of the slewing bearing 51, and the driving cylinder 53 The output end of the rack is connected with the rack 52 and drives the rack 52 to move back and forth, and the rack 52 meshes with the transmission teeth of the outer ring of the slewing bearing 51 . The driving cylinder 53 drives the rack 52 to move, and the rack 52 drives the outer ring of the slewing bearing 51 to rotate so as to drive the arm to rotate.

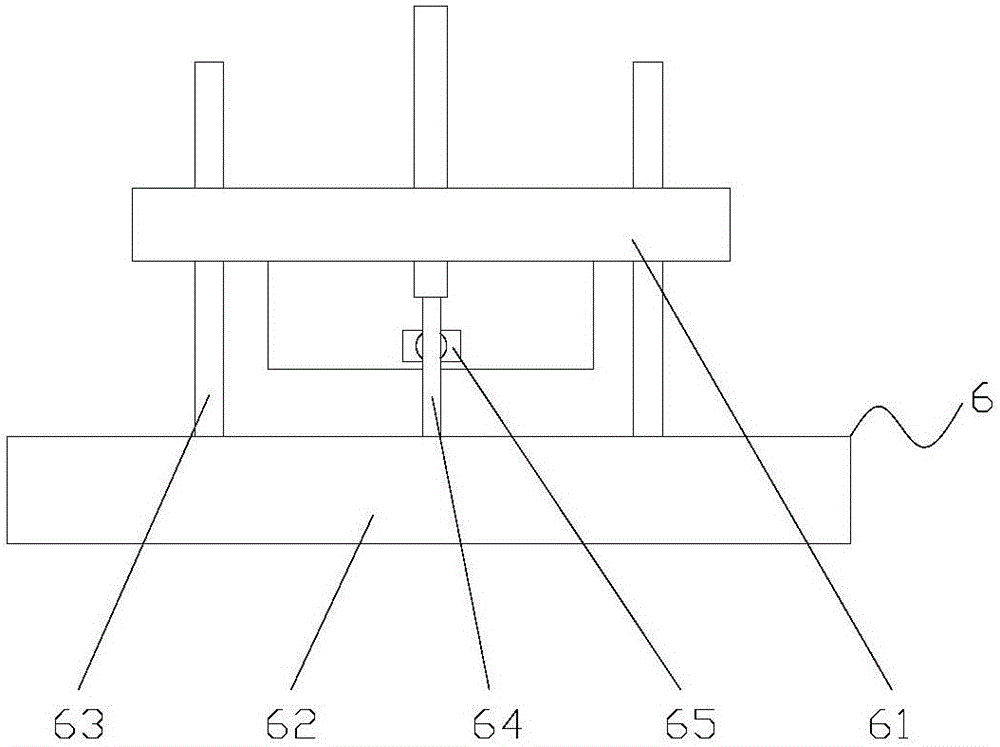

[0025] In addition, the two ends of the vehicle frame 1 and the working position of the cockpit 2 are respectively provided with buffer mechanisms 6 in place, such as image 3 As shown, the buffer mechanism 6 in place includes a base 61, a buffer plate 62, a guide rod 63, a buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com