Turnover channel for electrical appliance manufacturing

A channel and electrical technology, which is applied in the field of turning channels, can solve problems such as low operation efficiency, damage to the surface of the box, and long travel of the mechanism, so as to achieve the effects of improving production efficiency, avoiding shaking and impact, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

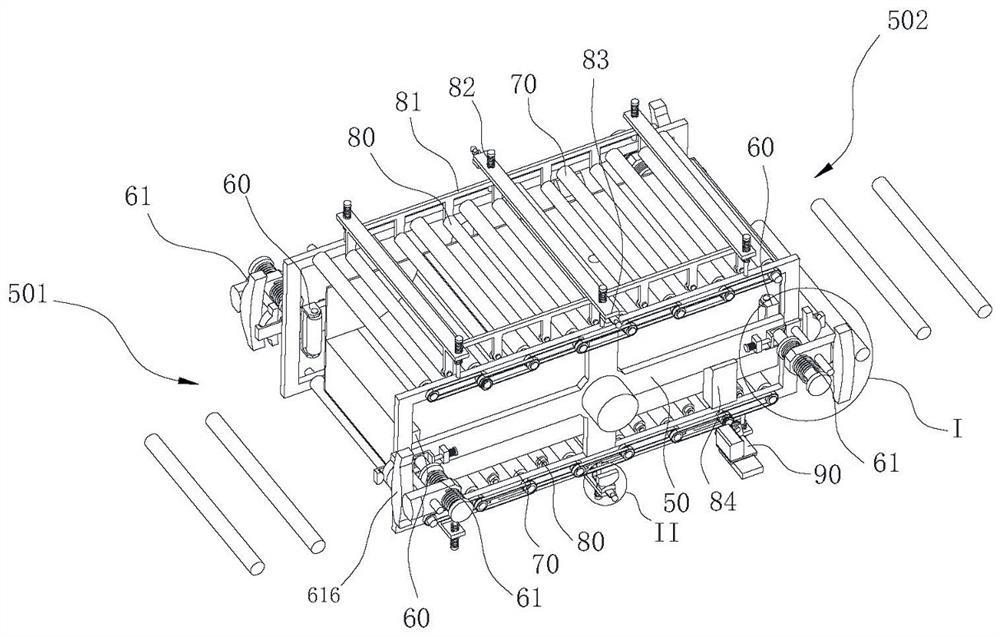

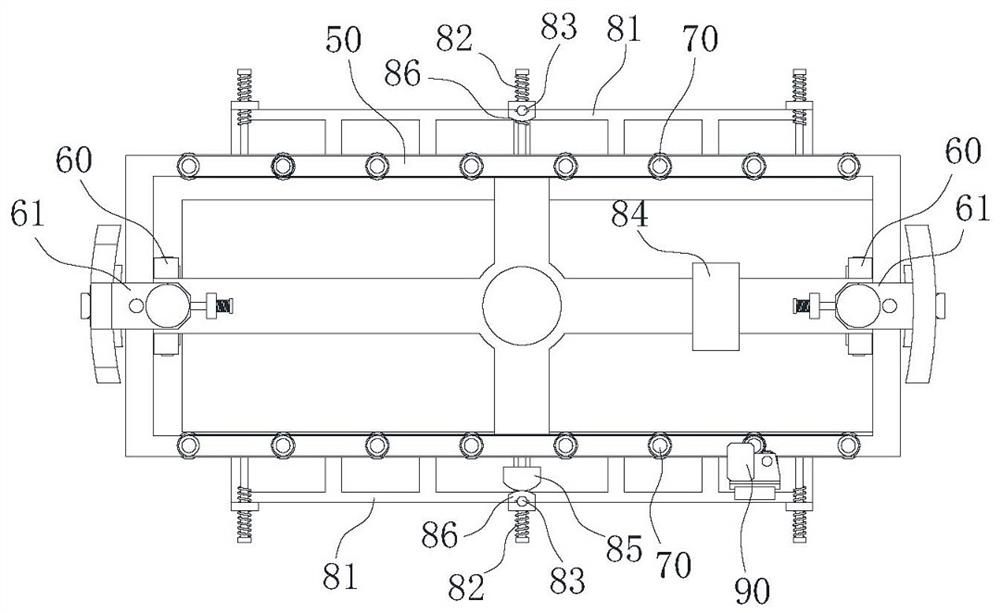

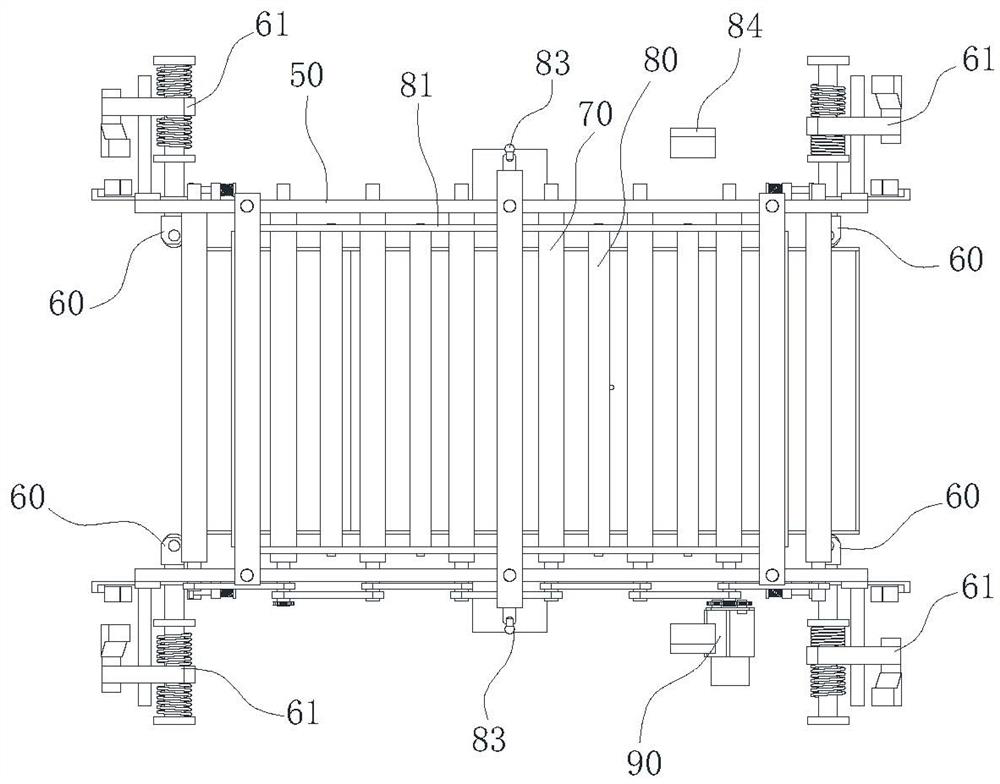

[0028] Such as figure 1 , 2, shown in 3, a kind of overturn channel that is used for electric appliance manufacturing comprises overturn frame 50, and overturn frame 50 is arranged on the frame along the horizontal axis rotation, and overturn frame 50 is provided with the channel that passes through for material, and the length direction of channel and The turning axis of the turning frame 50 is vertical, and the both sides of the turning channel parallel to the axis of the turning frame 50 are provided with conveying rollers 70, and the conveying rollers 70 are arranged at intervals along the length direction of the turning channel, and the turning frame 50 is also provided with floating rollers 80. The floating rollers 80 are arranged in two rows and correspond to the conveying rollers 70 on both sides respectively. The floating rollers 80 are movably arranged on the overturn frame 50 and the floating rollers 80 are assembled to move between the following two stations: stati...

Embodiment 2

[0039] A method for cleaning the surface of a foaming box applying the inversion channel described in Example 1, comprising the steps of:

[0040] Step 1: Transfer the foamed box to the first cleaning station, with the back of the box facing up. At the first cleaning station, use a hand-held dry ice cleaning gun to clean the foaming agent overflowing from the back and sides of the box. cleaning;

[0041] Step 2: Send the box into the turning channel, and the turning channel turns the box over to face up, and then transports the box to the second cleaning station;

[0042] Step 3: At the second cleaning station, clean the front of the box and the surface of the inner tank with a hand-held dry ice cleaning gun;

[0043] In the step 2, the flipping method is:

[0044] Turn the overturning channel to a horizontal posture, adjust the material retainer 60 at the feeding end to station two, and adjust the material retainer 60 at the discharge end to station one;

[0045]The box is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com