Multifunctional workbench applied to clothing manufacturing

A clothing manufacturing, multi-functional technology, applied in the field of clothing manufacturing, can solve the problems of workers and manufacturers personal injury, slow hand perception, injury, etc., to avoid hand fatigue and injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

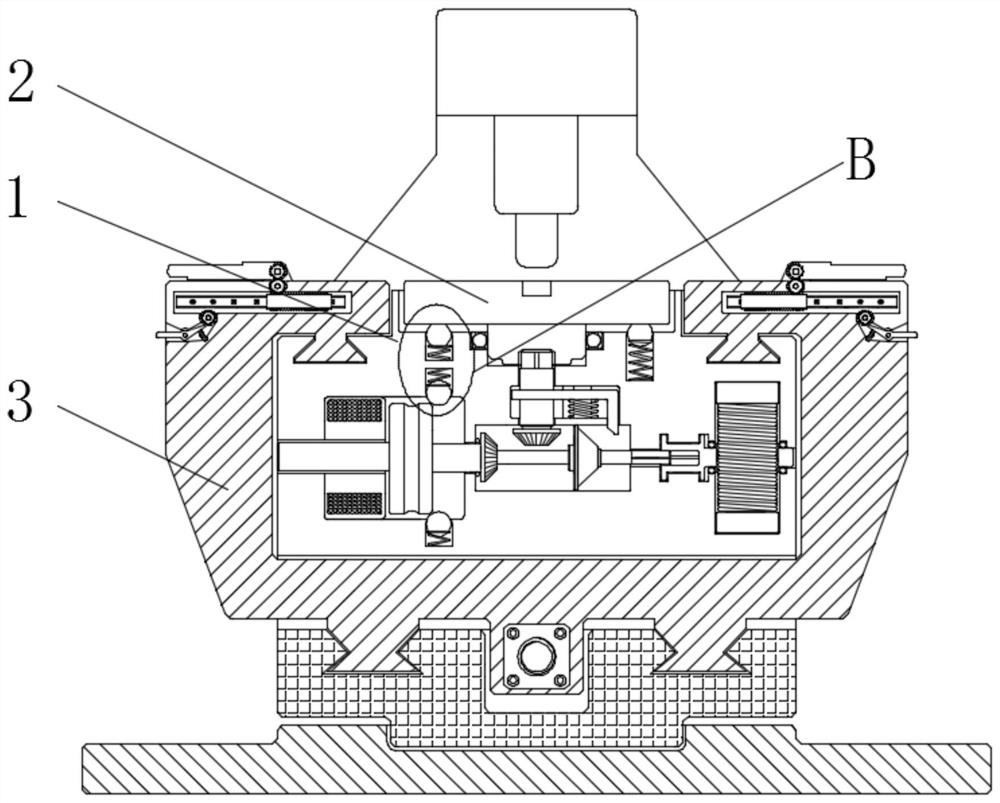

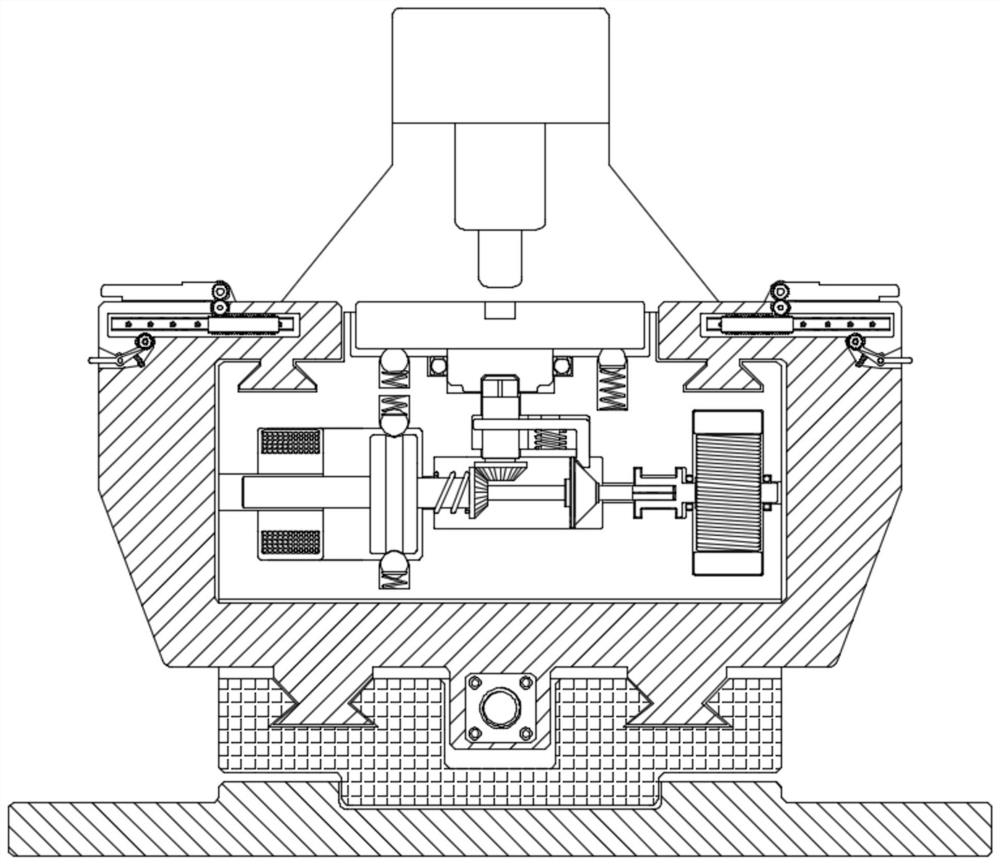

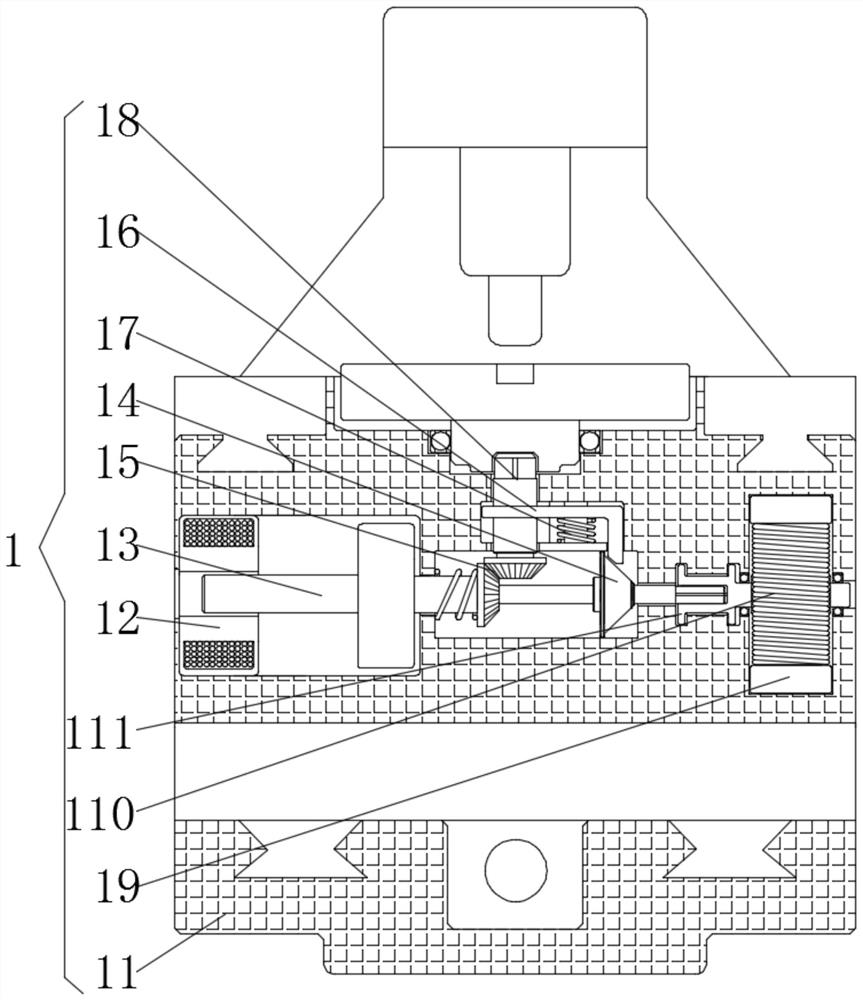

[0028] see Figure 1-6 with Figure 10 , a multifunctional workbench used in clothing manufacturing, including a turntable mechanism 1, the turntable mechanism 1 includes a rotating frame 11, the bottom of the rotating frame 11 is connected with a cylindrical rotating shaft, and the inside of the rotating frame 11 is equipped with a The matching rectangular chute, the bottom of the rectangular chute is provided with a dovetail chute, the bottom of the rectangular chute is provided with a rectangular slot matching the feed screw 32, the top of the rotating frame 11 is provided with a dovetail chute, and the top of the rotating frame 11 A circular slot adapted to the slot expansion mechanism 2 is provided, and a magnetic distance ring 12 is arranged inside the rotating frame 11, and the magnetic distance ring 12 includes a ceramic ring 121, and the inner winding of the ceramic ring 121 is connected with an electromagnetic coil 122, and the ceramic ring 121 The right side is pro...

Embodiment 2

[0032] see Figure 7-9 , a multifunctional workbench applied to clothing manufacturing, also includes a feed mechanism 3, the feed mechanism 3 includes a feed frame 31, the bottom of the feed frame 31 is screwed with a feed screw 32, and the top of the feed frame 31 Rotation is connected with pressure plate 33, and the bottom of pressure plate 33 is provided with pressure gear 34, and the inside of feed frame 31 is connected with fixed slide rail 36, and the outer side of fixed slide rail 36 is slidably connected with slide rack 35, and the outer side of slide rack 35 The top and the bottom are respectively provided with racks adapted to the pressure gear 34 and the brake gear 37, the inside of the feed frame 31 is connected to the brake gear 37 for rotation, the front of the brake gear 37 is provided with a brake ratchet 38, and the brake The bottom of the ratchet 38 is meshed with a reset lever 39, the bottom of the reset lever 39 is provided with a compression spring 310, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com