A kind of preparation method of metal porous material

A technology of porous metal and metal powder, which is applied in the field of preparation of porous metal materials, can solve problems such as difficult forming and powder removal, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

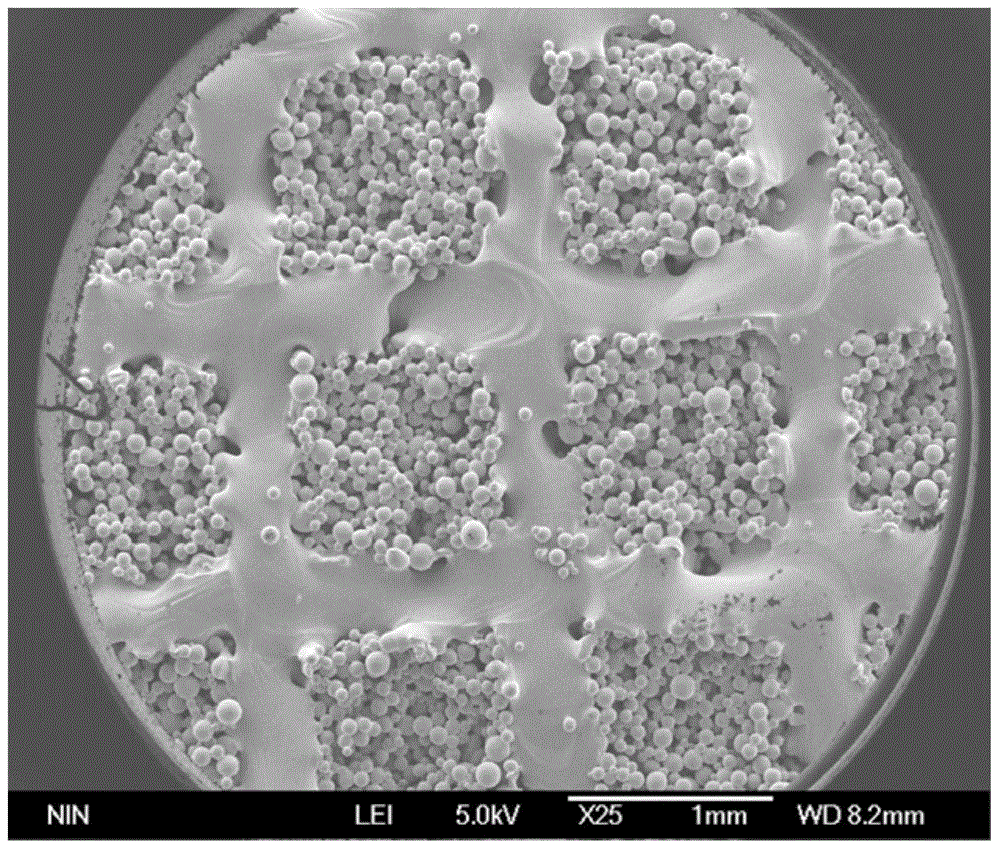

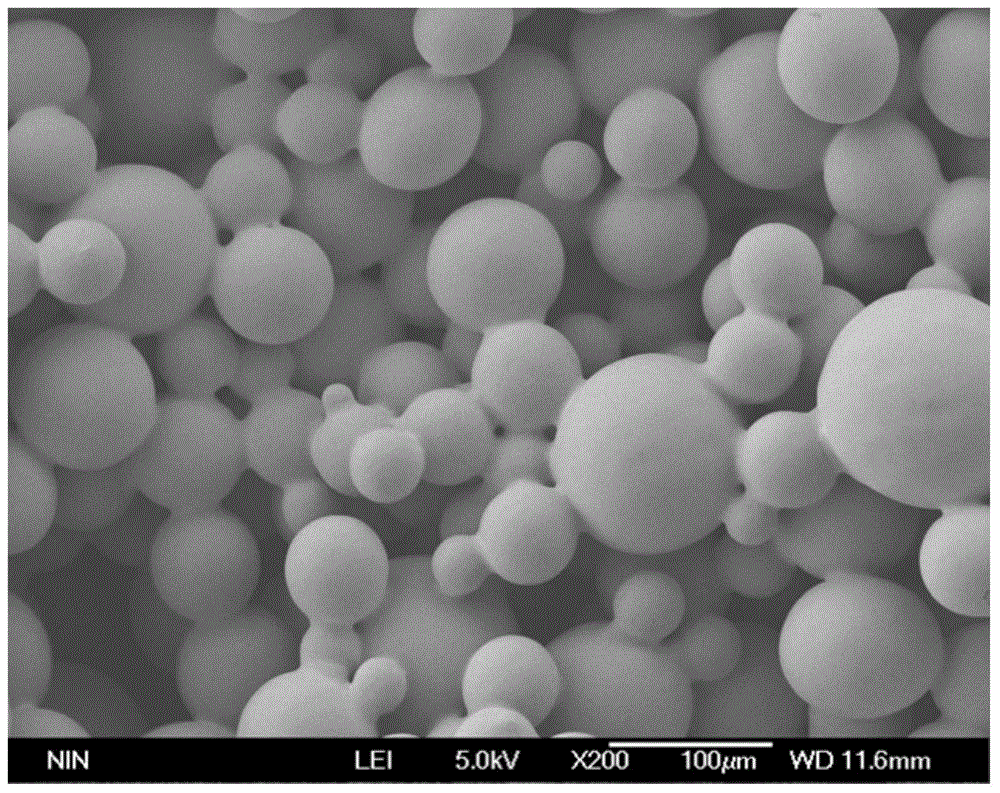

[0032] The material of the metal porous material to be prepared in this embodiment is NiCr alloy, and the specific specification is 30mm (length) × 30mm (width) × 3mm (height). The porous sintered body inside the entire three-dimensional grid structure of the frame, the grid size of the three-dimensional grid structure is 1mm×1mm×1mm, the average pore diameter of the micropores in the porous sintered body is about 30 μm to 100 μm, the metal Porous materials can be applied to gas-solid separation materials.

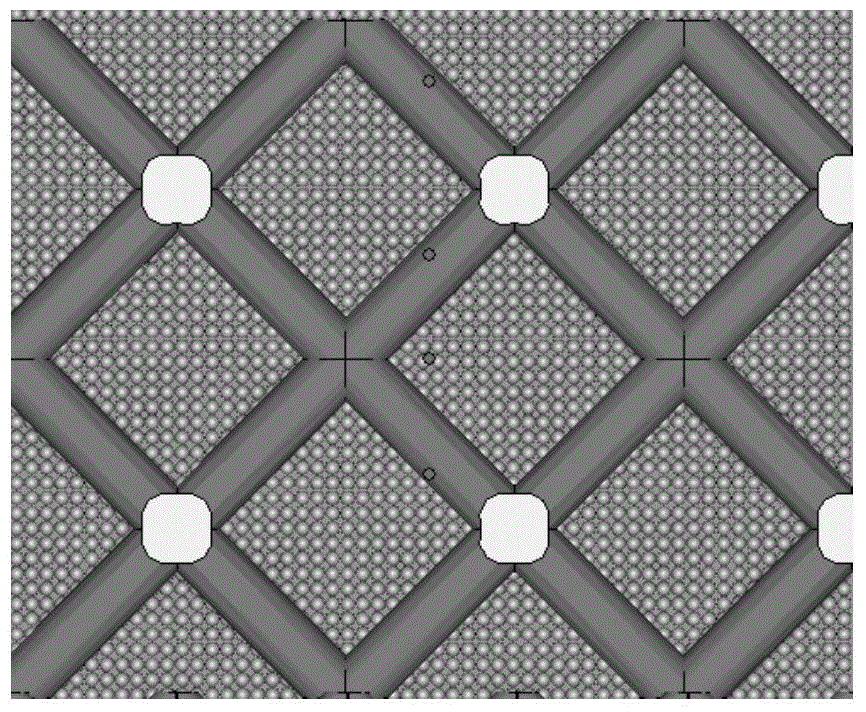

[0033] The three-dimensional solid model of the metal porous material to be prepared in this embodiment is as follows figure 1 Shown, its specific preparation method comprises the following steps:

[0034] Step 1, according to the shape and size of the frame in the metal porous material to be prepared, use a three-dimensional modeling software to establish a three-dimensional solid model of the frame in a computer; the three-dimensional modeling software is preferably Aut...

Embodiment 2

[0041] The material of the metal porous material to be prepared in this embodiment is NiCr alloy, and the specific specification is 30mm (length) × 30mm (width) × 3mm (height). The porous sintered body inside part of the three-dimensional grid structure in the frame, wherein the height of the frame with the porous sintered body nested inside the three-dimensional grid structure accounts for 1 / 4 of the total height of the frame, and the grid size of the three-dimensional grid structure is 1mm × 1 mm × 1 mm, the average pore diameter of the micropores in the porous sintered body is about 30 μm to 100 μm, and the metal porous material can be applied to filter materials.

[0042] The three-dimensional solid model of the metal porous material to be prepared in this embodiment is as follows Figure 4 Shown, its specific preparation method comprises the following steps:

[0043] Step 1, according to the shape and size of the frame in the metal porous material to be prepared, use a t...

Embodiment 3

[0050] The material of the metal porous material to be prepared in this embodiment is Ti-6Al-4V alloy, and the specific specification is 100mm (length) × 70mm (width) × 20mm (height). The metal porous material includes a frame with a three-dimensional grid structure and A porous sintered body nested inside a part of the three-dimensional grid structure of the frame, the grid size of the three-dimensional grid structure is 0.5mm×0.5mm×0.5mm and 1mm×1mm×1mm from top to bottom, wherein A porous sintered body is nested inside a three-dimensional grid structure with a grid size of 0.5mm×0.5mm×0.5mm. The average pore diameter of the micropores in the porous sintered body is about 30 μm to 100 μm. This metal porous material can be applied to resistance combustible material.

[0051] The three-dimensional solid model of the metal porous material to be prepared in this embodiment is as follows Figure 5 Shown, its specific preparation method comprises the following steps:

[0052] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com