Cavity guide wire

A guide wire and cavity technology, applied in the field of medical devices, can solve the problems of increasing the surface friction coefficient of the distal end of the guide wire, unfavorable operator judgment and operation, and reducing the support of the distal end of the guide wire, and achieves good mechanical feedback, Good passability, smooth and uniform outer surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

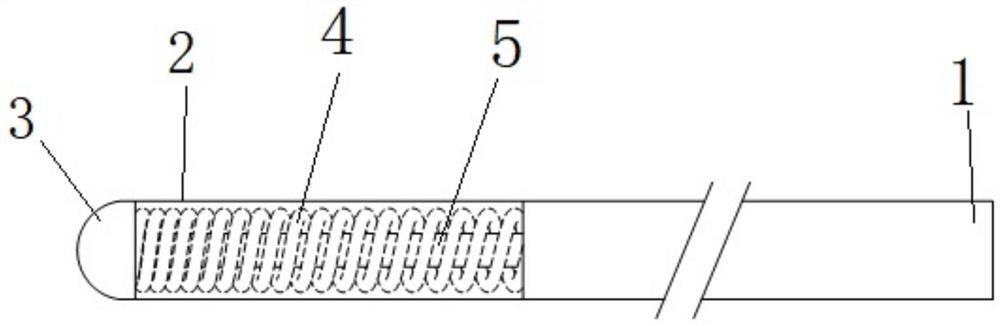

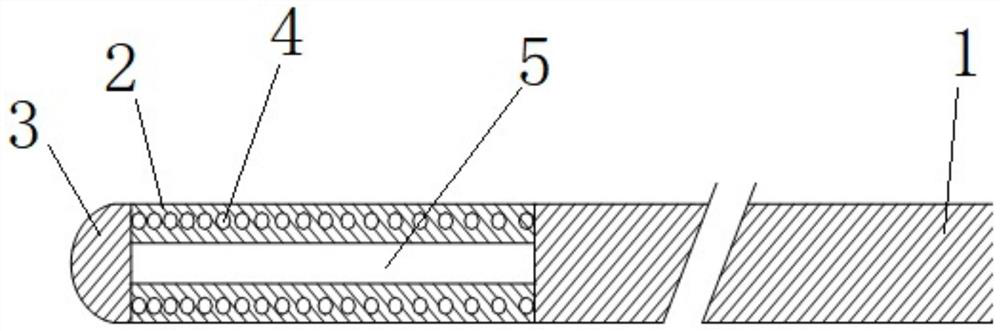

[0031] Such as figure 1, as shown in 2, is a structural schematic diagram of a guide wire of the present invention, the guide wire has an integral structure from the guide wire proximal end 1 to the guide wire distal end 2 and the head end 3, and the head end 3 is designed in a dome shape. The proximal end 1 of the guide wire is equal to the diameter of the distal end 2 of the guide wire. When the proximal end 1 of the guide wire is rotated, the torque can be transmitted to the distal end 2 of the guide wire and the tip 3 of the guide wire in a timely manner, thus having good torque control; And because the guide wire is an integral structure, the guide wire tip 3 and the guide wire distal end 2 can directly and effectively transmit the received force to the guide wire proximal end 1 during use; the diameter of the guide wire distal end 2 is compared with that of the guide wire near End 1 is not reduced, so it has better support and is more suitable for cooperation with other ...

Embodiment 2

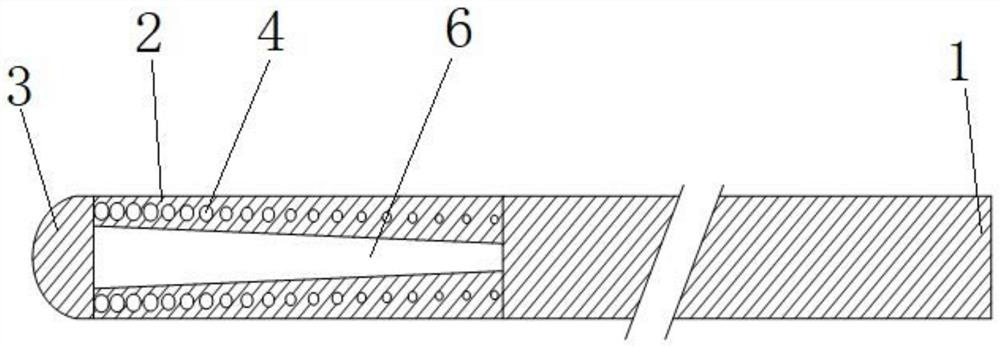

[0035] Such as image 3 shown, is figure 1 and figure 2 A cross-sectional view of an improved form of the guide wire shown in , the guide wire is an integral structure from the guide wire proximal end 1 to the guide wire distal end 2 and the head end 3, the head end 3 is designed in a dome shape, and the guide wire near End 1 and distal end 2 are equal in diameter.

[0036] The shaded part in the figure is the entity, and the rest are the helical cavity 4 and the conical cavity 6. The diameter of the helical cavity 4 and the cross-sectional diameter of the cavity are from the part close to the proximal end 1 of the guide wire to the part close to the guide wire. The portion of the distal end 2 increases gradually, while the pitch of the helix gradually decreases; meanwhile, the diameter of the conical cavity 6 gradually increases from the portion close to the proximal end 1 of the guide wire to the portion close to the distal end 2 of the guide wire.

[0037] This improved...

Embodiment 3

[0039] Such as Figure 4 As shown, it is a schematic cross-sectional view of a guide wire with a cavity structure inside the distal end. The guide wire has an integral structure from the proximal end 1 of the guide wire to the distal end 2 of the guide wire and the head end 3 of the guide wire. The head end 3 is Dome-shaped design, the diameter of the proximal end 1 of the guide wire is equal to that of the distal end 2 of the guide wire.

[0040] The shaded part in the figure is a solid, and the rest is a cavity. The cavity is a combined cavity of a conical cavity 6 and an annular cavity 7, from 1 near the proximal end of the guide wire to 2 near the distal end of the guide wire. , due to the increase in the volume of the cavity, the degree of reduction in the structural stress of the guidewire entity along the guidewire axis is further expanded, so that the distal end 2 of the guidewire is compared to figure 1 / figure 2 and image 3 The guidewire shown in has more excel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com