Automobile part injection molding buckle impact test device

A technology for auto parts and impact testing, applied in impact testing, testing of machine/structural components, measuring devices, etc., can solve the problem that the size of the impact surface of the impact hammer head and the impact weight cannot be adjusted flexibly, affecting the overall stability, and the lifting structure Wear and other problems, to achieve light weight, ensure stability, reduce the effect of equipment wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

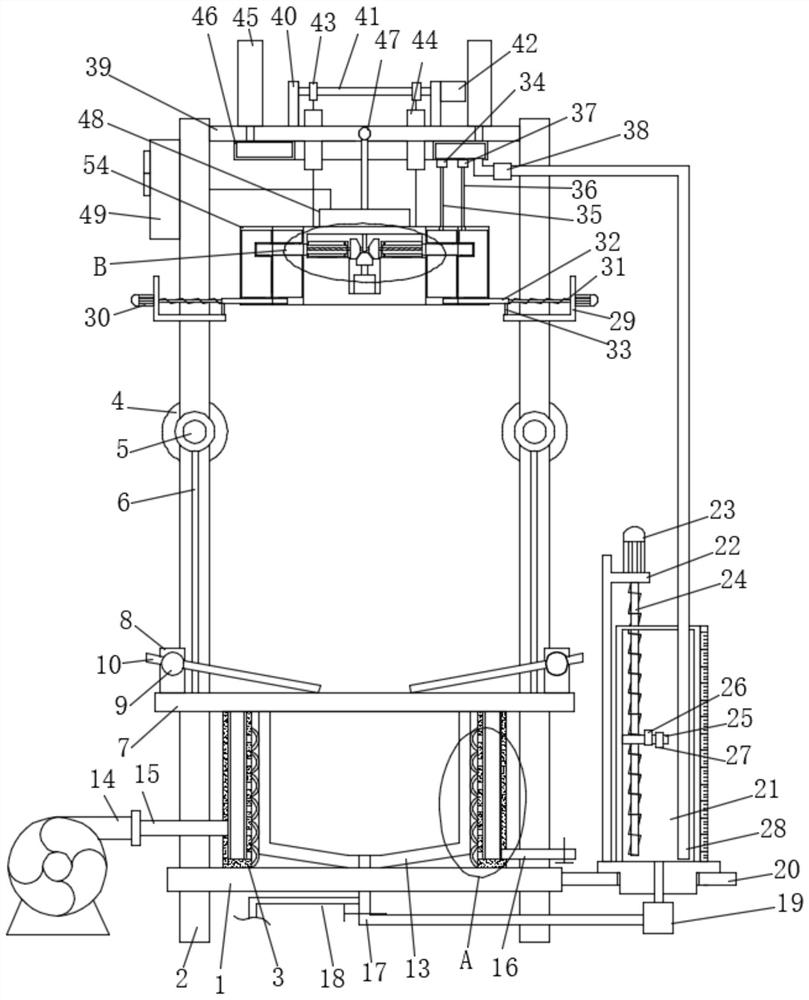

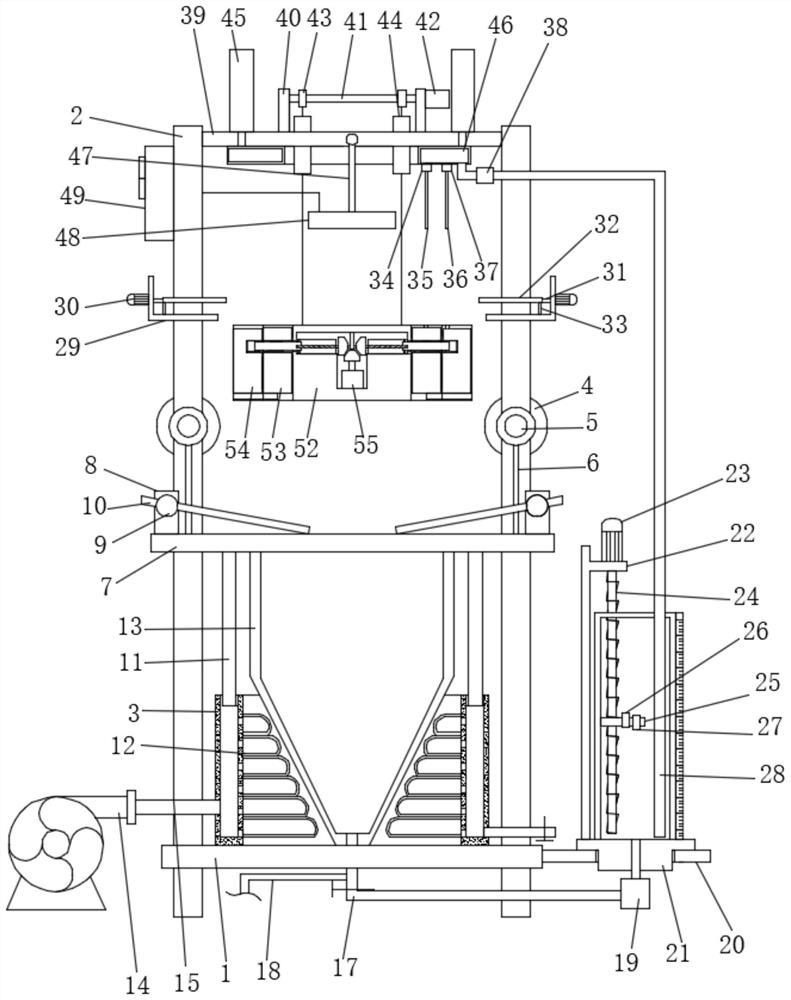

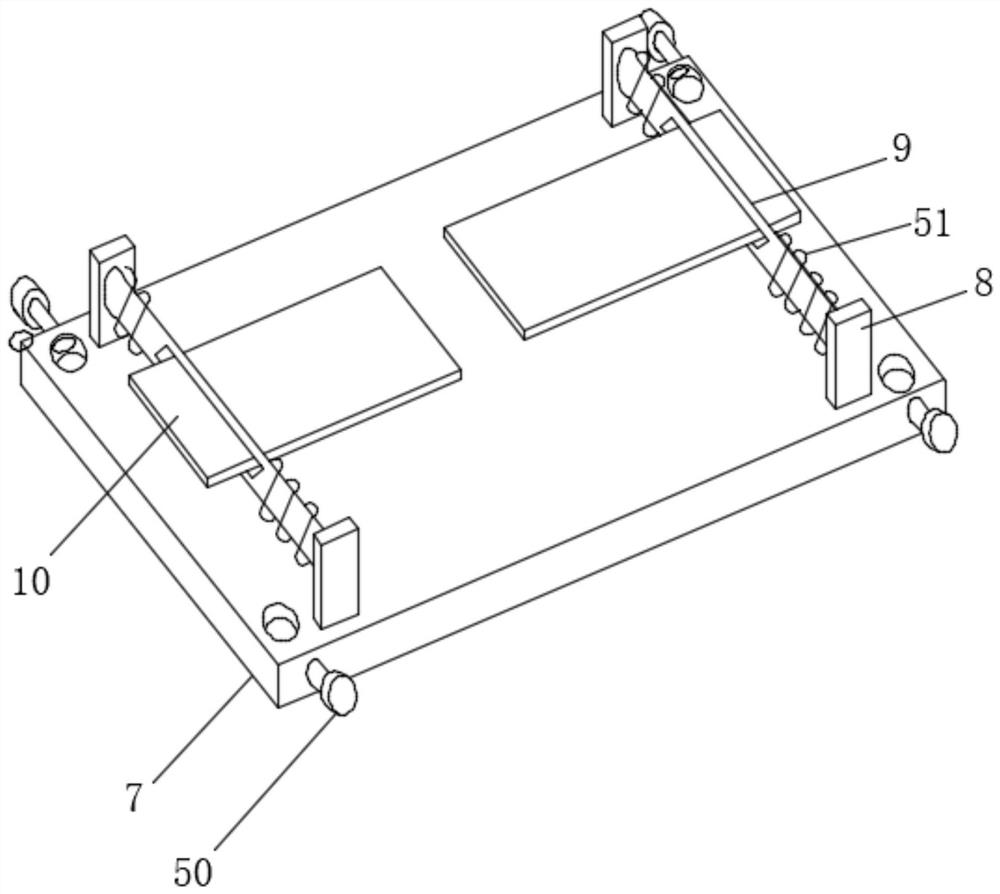

[0030] See Figure 1-10An injection molded automotive parts snap-impact testing apparatus, an injection molded automobile parts snap-impact testing apparatus includes a base 1, the base 1 are respectively fixed to the four corners of the support post 2 is inserted, and is fixedly mounted on the base 1 with a water tank 3, tank 3 is placed on the impact plate 7, and the bottom end of the impact plate 7 fixedly mounted water film 13, water film 13 placed in the tank 3, and the water film 13 is fixed to the bottom nozzle end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com