Exhaust throttle valve

An exhaust throttle valve and valve body technology, which is applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of low life and high failure rate of exhaust throttle valve, and achieve cost reduction, simple structure, and improved performance. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

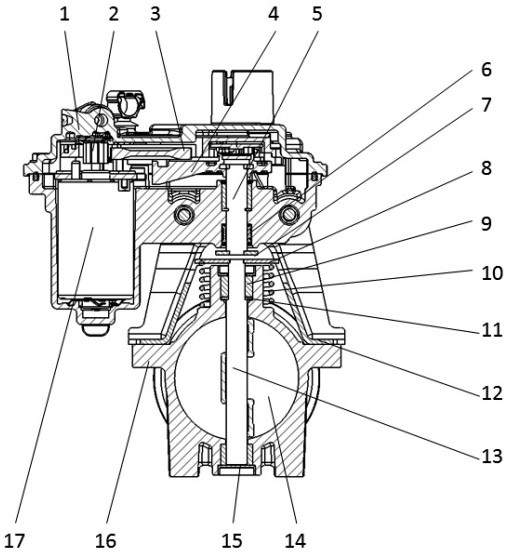

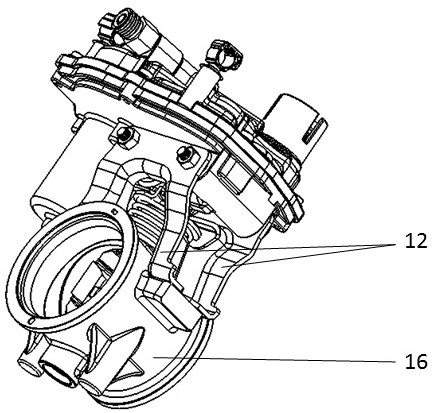

[0025] see Figure 1 to Figure 6 , a preferred embodiment of the exhaust throttle valve of the present invention is composed of a valve body 16, a driven mechanism, a transmission mechanism, a speed change mechanism and a power mechanism. When the power mechanism outputs power, the power mechanism drives the second transmission device through the transmission mechanism, and drives the first transmission device to make the driven mechanism act. When the power mechanism does not output, the first transmission device drives the driven mechanism to return to the initial position.

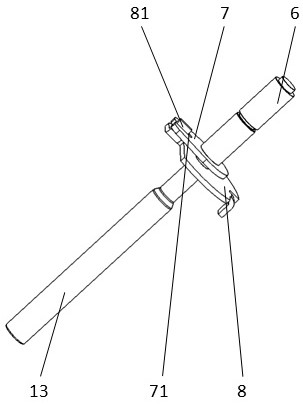

[0026] The driven mechanism is located in the valve body 16 and includes the throttle plate 14 and the valve shaft 13 . The valve shaft 13 passes through the valve body 16, and the throttle plate 14 is rigidly fixed on the valve shaft 13, driven to rotate by the valve shaft 13, and regulates the gas flow rate of the exhaust throttle valve. A needle roller bearing 6 is arranged at the end of the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com