Rotor compressor assembly and air conditioner

A technology of rotor compressors and components, applied in the field of compressors, can solve the problems of reduced volumetric efficiency and energy efficiency of the pump body, improve cooling capacity and energy efficiency, improve reliability, and solve the effects of reduced volumetric efficiency and energy efficiency of the pump body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

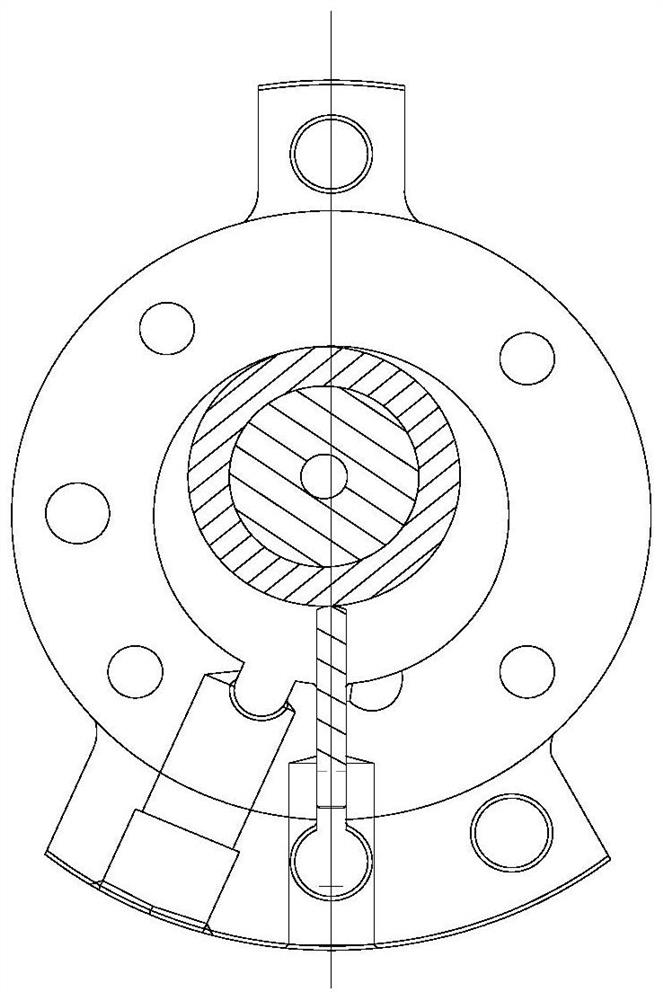

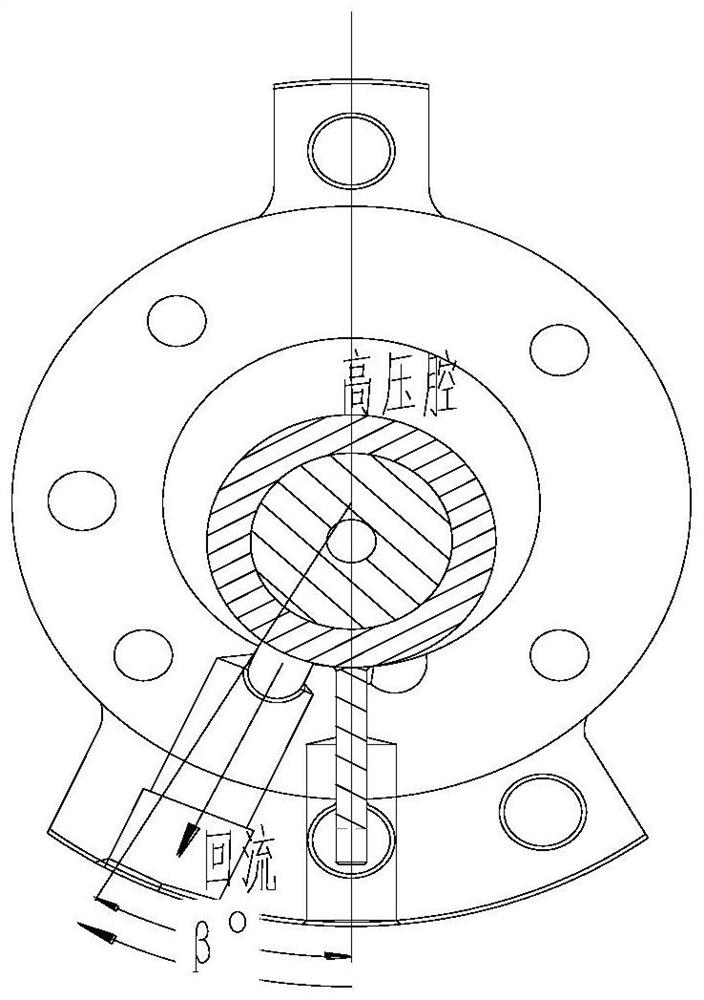

[0041] Embodiment one, such as Figure 4-7 As shown, in some embodiments, the first non-return structure 3 includes a first channel 31 and a second channel 32, the opening of the first channel 31 and the opening of the second channel 32 are respectively connected to the The suction pipe 2 communicates, the other end of the first passage 31 communicates with the other end of the second passage 32, and the opening of the first passage 31 is opposite to the direction in which the gas of the suction pipe 2 flows backwards, so as to The gas can be introduced into the first passage 31, and then enter the second passage 32 and be discharged into the suction pipe 2, the opening of the second passage 32 flows backwards from the gas in the suction pipe 2 in the opposite direction. This is the preferred structural form of Embodiment 1 of the present invention, that is, the first non-return structure consists of two channels that are roughly in a U-shaped structure, the first channel is ...

Embodiment 2

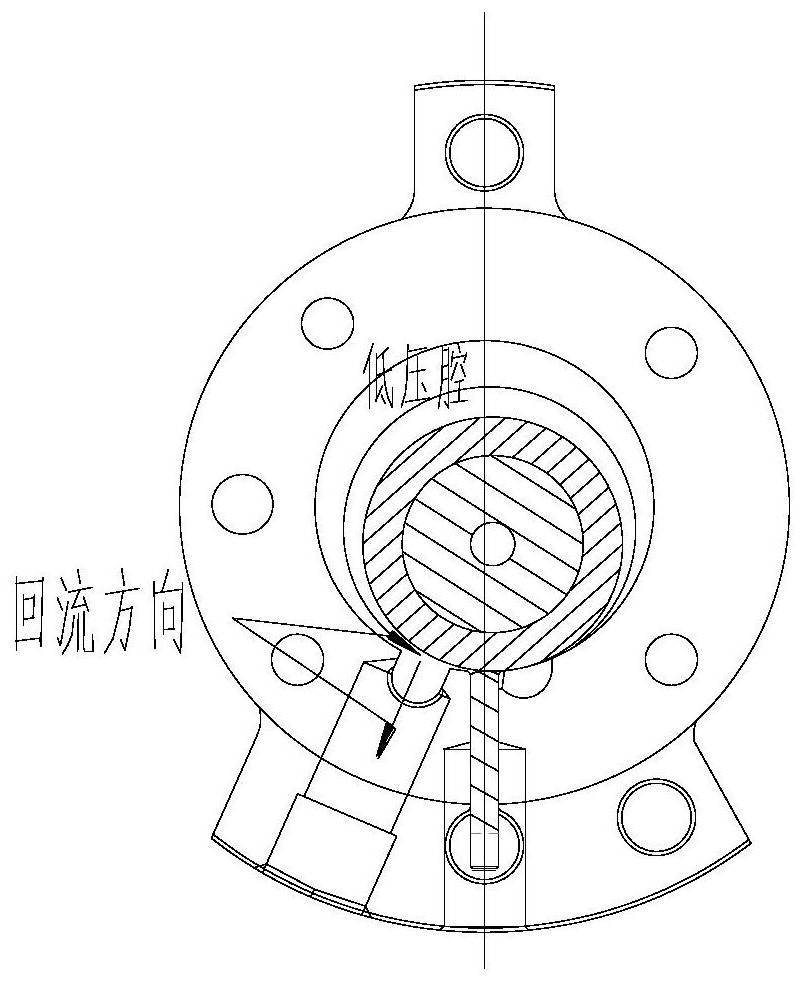

[0046] Embodiment two, such as Figure 8 As shown, in some embodiments, the second non-return structure 4 includes a third channel 41 and a fourth channel 42 opened on the cylinder 1, and the third channel 41 and the fourth channel 42 are both communicate with the suction passage 11 respectively, the other end of the third passage 41 communicates with the other end of the fourth passage 42, and the opening of the third passage 41 is compared with the opening of the fourth passage 42 Closer to the inside of the cylinder 1, so that when the airflow flows backward in the suction pipe 2, it first enters the third passage 41 through the opening of the third passage 41, and then returns through the fourth passage 42 To the inhalation channel 11 , the direction of the airflow flowing out of the fourth channel 42 has a component direction, and the component direction is opposite to the reverse flow direction of the airflow in the inhalation channel 11 . This is the preferred structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com