Expansion valve coil

An expansion valve coil and coil technology, which is applied in the field of expansion valve coils, can solve the problems of high defect rate and poor structural strength, and achieve the effects of low defect rate, improved structural strength and good structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

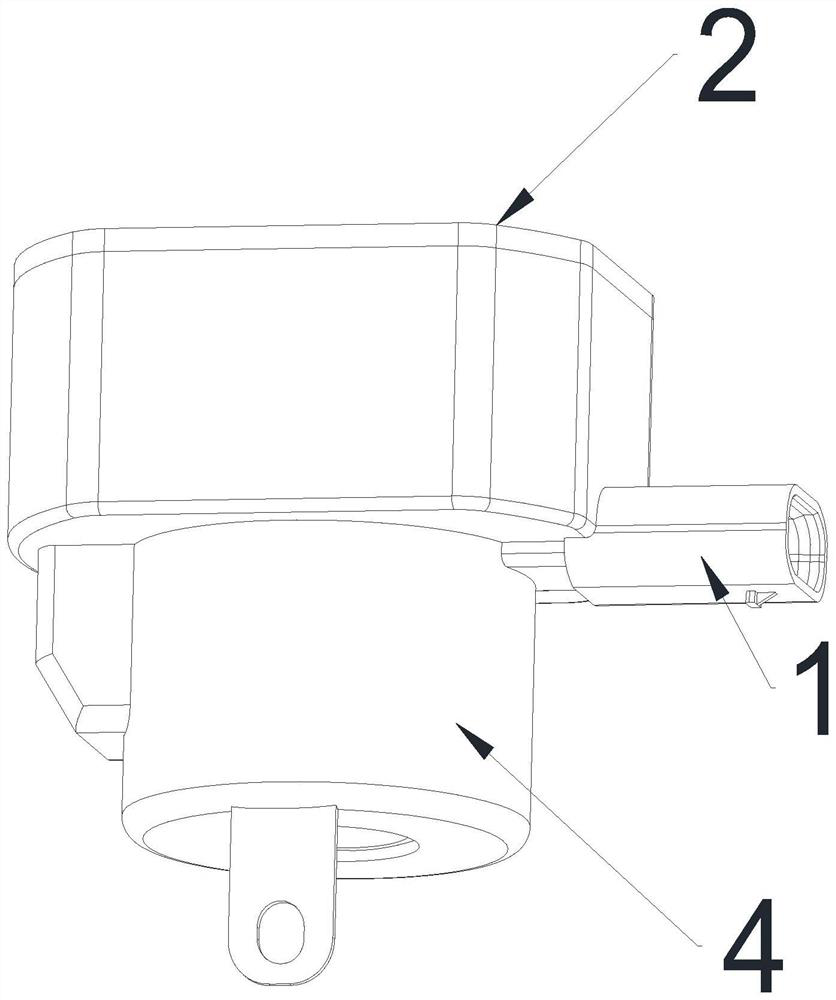

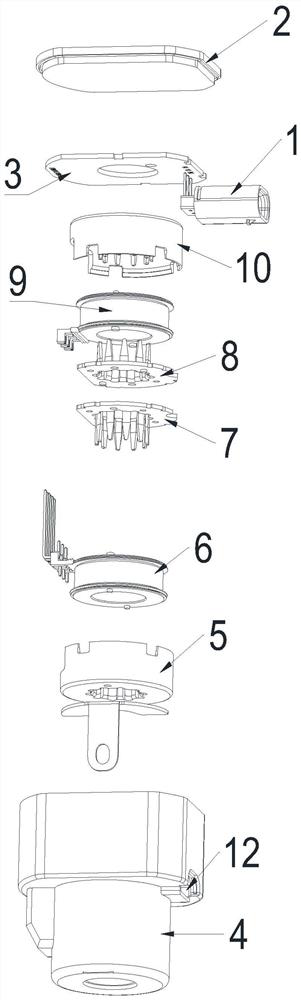

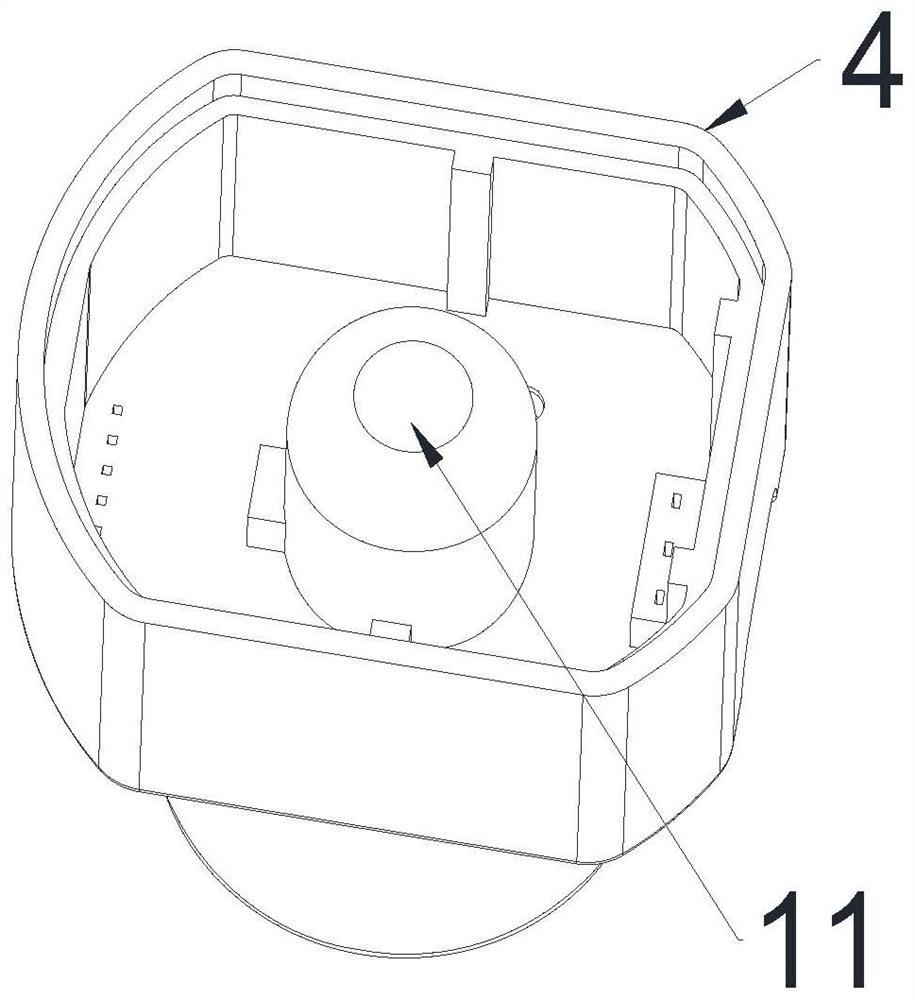

[0026] combined with Figure 1-4 , an expansion valve coil, including a joint assembly 1, a box body 4 and a box cover 2, the inside of the box body 4 is provided with a cylindrically wound coil, the joint assembly 1 includes pins, and the box body 4 A groove 12 adapted to the shape of the joint assembly 1 is provided on the side, and a hole for passing through a pin is provided on the groove 12, and the hole is located in the axial direction of the coil, and the box body 4 is matched with the box cover 2 through a step structure, the box cover 2 is located on the axial section of the coil, the inside of the box body 4 is filled with glue, and the surface of the joint assembly 1 is provided with the box The positioning groove 13 matched with the body 4.

[0027] The joint assembly 1 is used to connect the internal coil and external components, and the box body 4 and the box cover 2 are used to protect the coil. In this embodiment, the body is in the shape of an inverted boss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com