Array graph drawing method and system

A graphics drawing and array technology, applied in the field of lithography, can solve the problems of long conversion time, affecting printer work efficiency, low conversion efficiency, etc., and achieve the effect of avoiding time waste, saving drawing time and avoiding material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

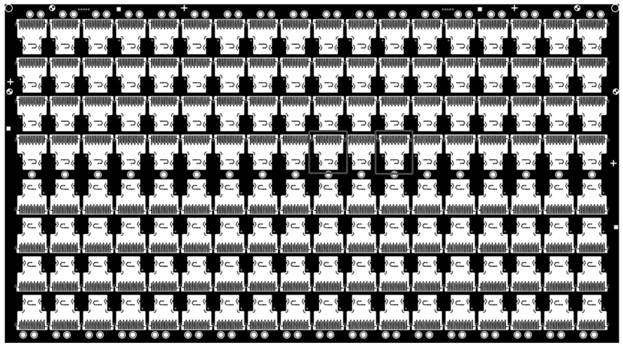

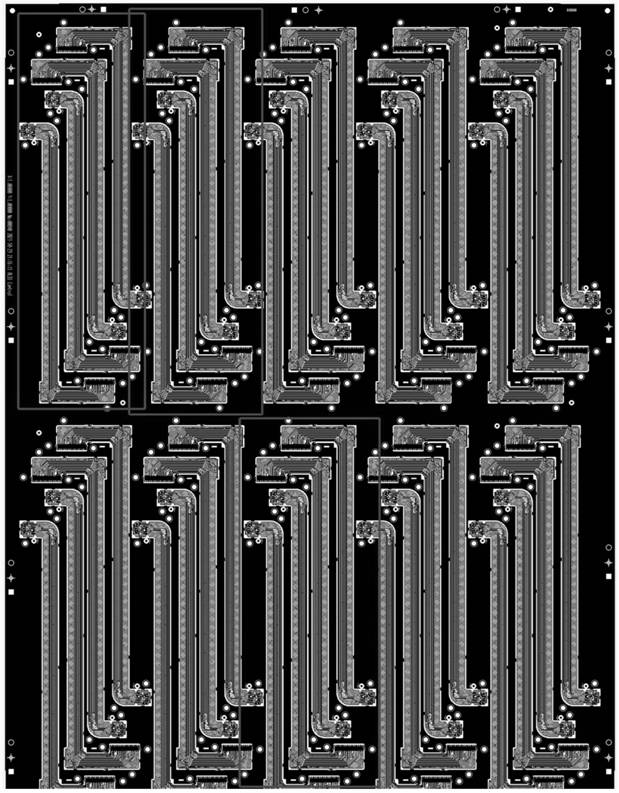

[0037] like figure 1 and figure 2 Shown is the circuit diagram on a conventional PCB board, because there are a large number of repetitive patterns on the circuit on the PCB board (such as figure 1 and figure 2 shown in the red box), and many of them have obvious array characteristics. The graphics are composed of a variety of unpassable units, and there are clear boundaries between units, and the units do not overlap each other. Therefore, the present invention provides A high-efficiency drawing method for array graphics is presented.

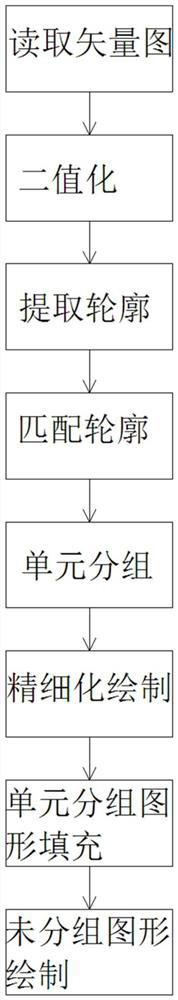

[0038] like image 3 As shown, the method includes the following steps:

[0039] S1; read the vector image file;

[0040] S2, binarizing the vector image file;

[0041] S3, extracting the contour in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com