Glass panel surface defect detection method based on small sample learning

A glass panel, defect detection technology, applied in neural learning methods, image data processing, image enhancement and other directions, can solve the problem of inaccurate labeling of small objects, etc., to improve detection accuracy, improve performance indicators, and enhance the effect of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

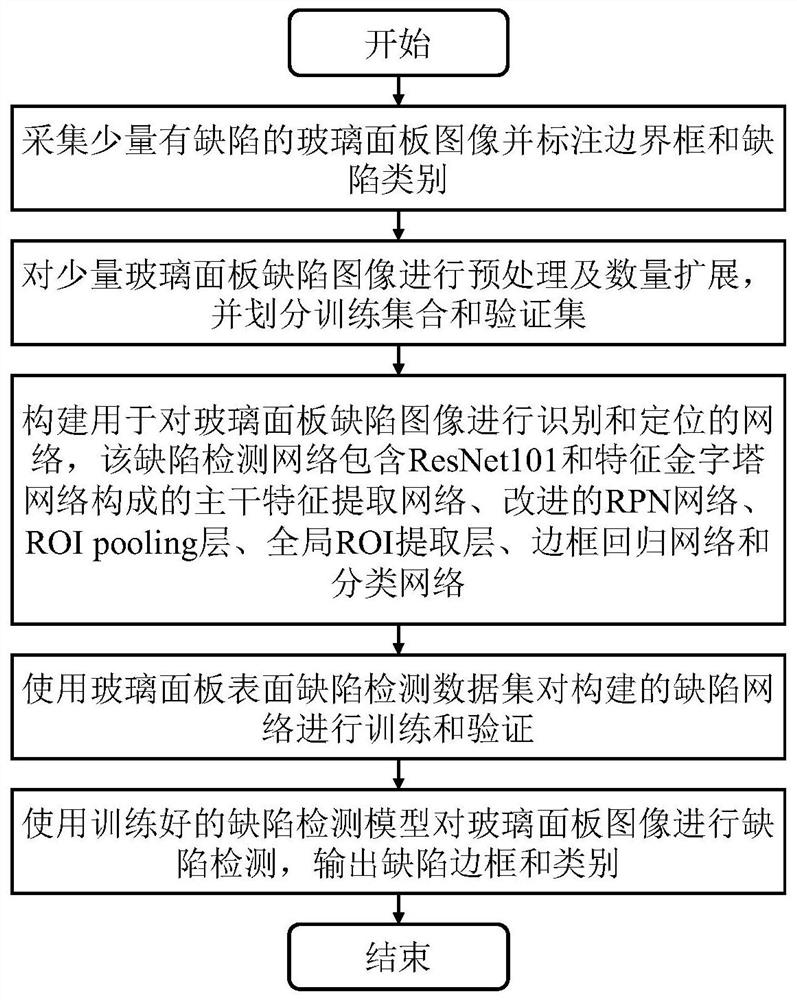

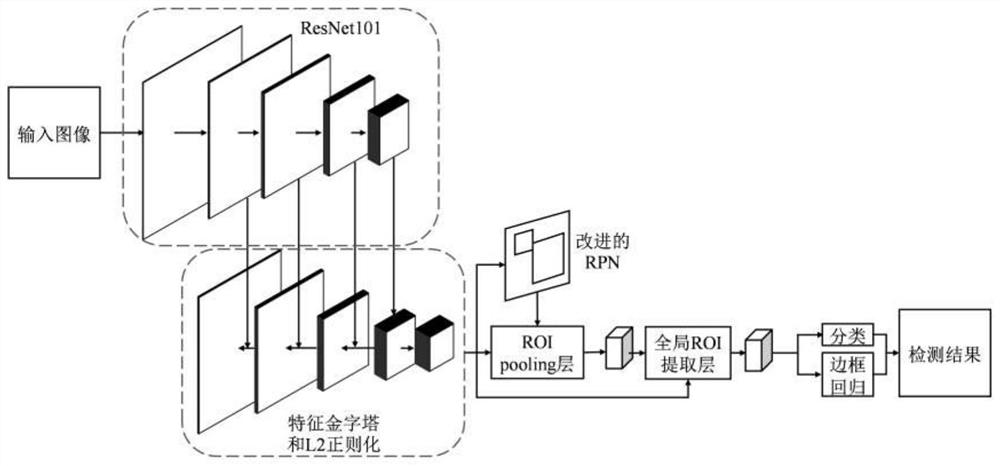

[0027] The overall flow chart of a glass panel surface defect detection method based on small sample learning disclosed by the present invention is as follows figure 1 As shown, the specific implementation process is as follows:

[0028] (1) Collect a small number of defective glass panel images. Use the labeling software labelImg to label each picture and generate an xml file. The xml file contains the bounding box of the defect and the defect category. The defect categories include bubbles, tin dust, pinholes, and scratches.

[0029] (2) Preprocess and expand the number of glass panel images to construct a glass panel surface defect detection data set.

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com