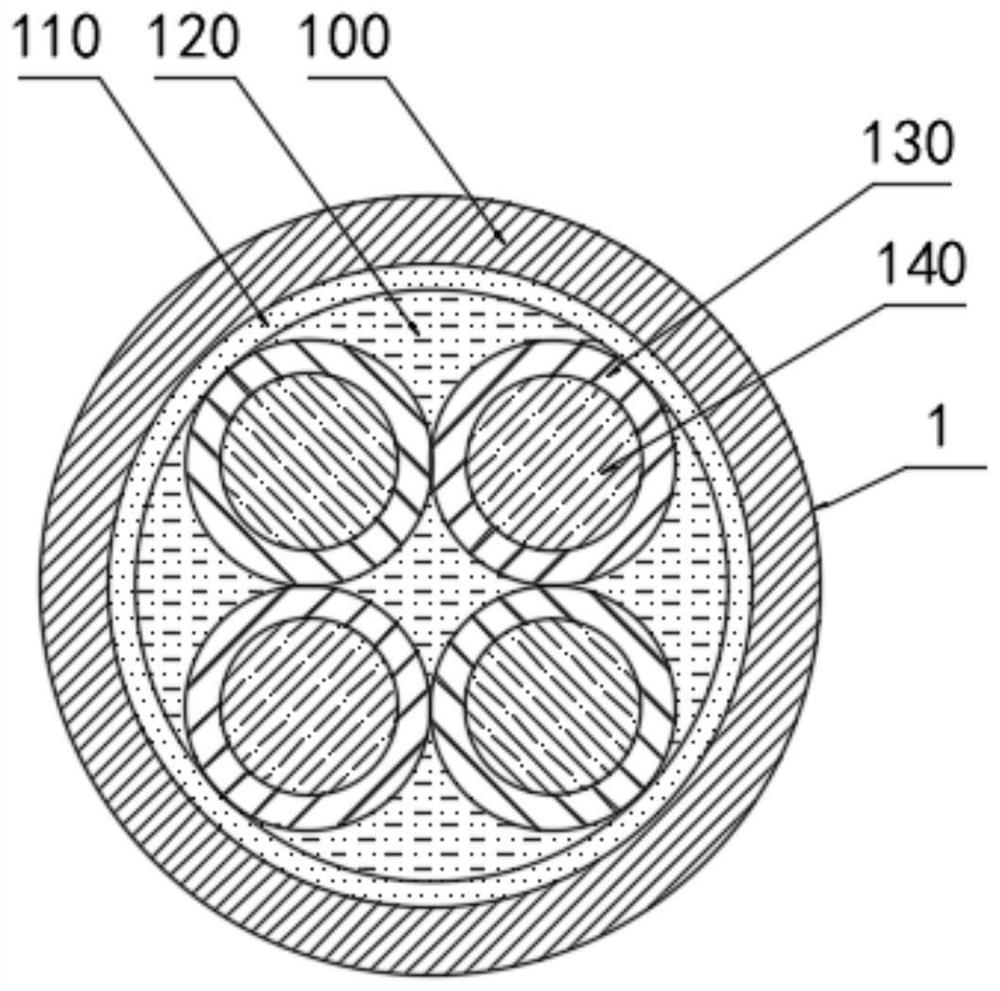

Ethylene propylene rubber insulated salt-spray-resistant rubber jacketed flexible cable

An ethylene-propylene rubber insulation and anti-salt spray technology, which is applied in the direction of insulated cables, insulated conductors, and bendable cables, can solve the problems of difficult control of wire tightness, low efficiency of conductor stranding, and poor quality stranding conductors. Achieve the effects of high stranding efficiency, improved stranding quality, and fewer stranding processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

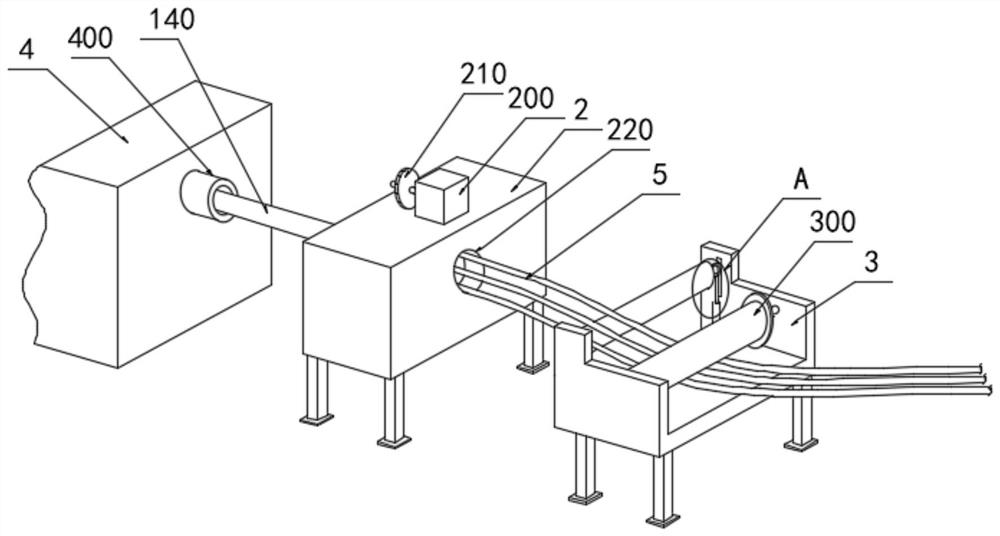

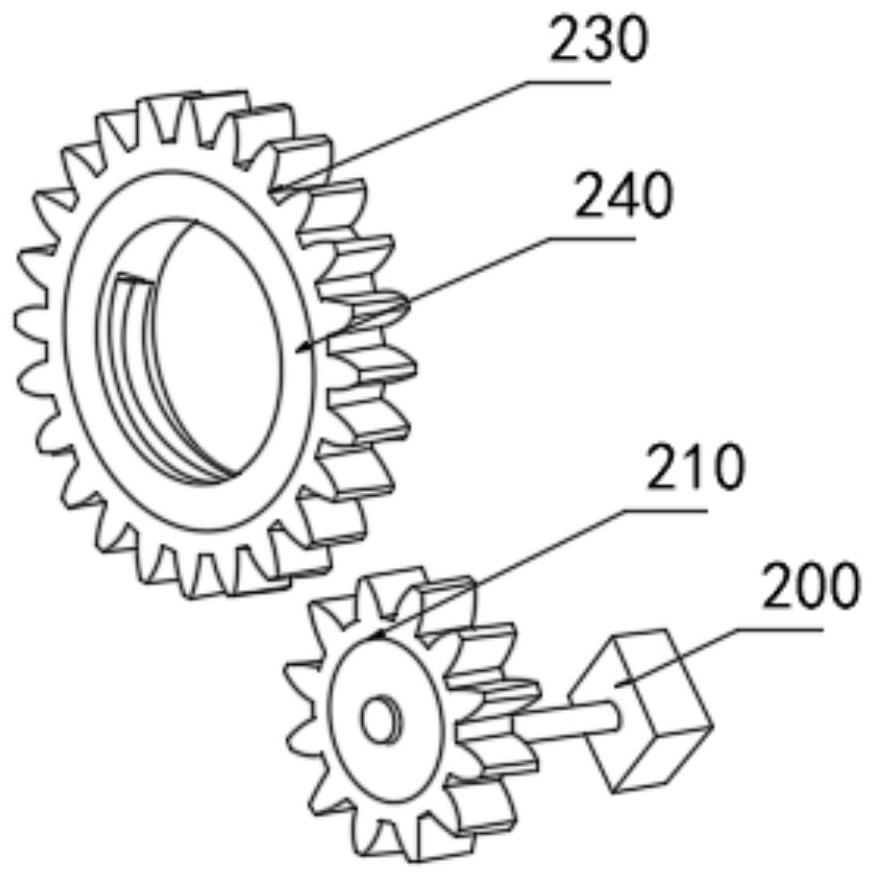

[0031] The conductor 140 is made by twisting a plurality of twisted conductors 5, and the ends of the many twisted conductors 5 pass through the inside of the conductor stranding chamber 2, and the top of the conductor stranding chamber 2 is equipped with a driving motor 200, and the output of the driving motor 200 The end of the shaft is fitted with a gear 210, and the bottom end of the gear 210 is meshed with an outer ring gear 230 arranged inside the conductor stranding chamber 2. The inner wall of the outer ring gear 230 is fixed with a twisting seat 240, and the inner wall of the twisting seat 240 is symmetrical. Two accommodating chambers 250 are provided, and the twisting seat 240 is provided with a stranded chamber 220 communicating with the accommodating chamber 250. A miniature electric push rod 260 is installed inside the accommodating chamber 250, and the telescopic end of the miniature electric push rod 260 is fixedly connected. There is a stranding pressure plate ...

Embodiment 2

[0035] One side of the conductor stranding chamber 2 is provided with a take-up chamber 4, and the other side of the conductor stranding chamber 2 is provided with a transmission frame 3, and the inside of the transmission frame 3 is provided with a tension guide roller 300, and the top of the tension guide roller 300 is The pressure regulating roller 310 is arranged on the side, and the two ends of the pressure regulating roller 310 are equipped with a shaft 320. The outer surface of the shaft 320 is movably fitted with a sliding sleeve 330, and the bottom end of the inner cavity of the transmission frame 3 is installed with a sliding sleeve. The ring 330 is fixedly connected to the hydraulic rod 350 , and the inner wall of the transmission frame 3 is provided with a guide rail 340 slidably connected to the shaft rod 320 .

[0036] When twisting a plurality of twisted wires 5, in order to improve the quality of twisting, the sliding collar 330 is set on the two shafts 320 of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap