Full-hydraulic-drive high-ground-clearance central-laying rape cutting and drying platform

A high ground clearance, full hydraulic technology, applied in the direction of headers, harvesters, agricultural machinery and implements, etc., can solve the problems of poor laying consistency, low operation efficiency, and small amount of laying on one side, and achieve reliable positioning, installation or The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

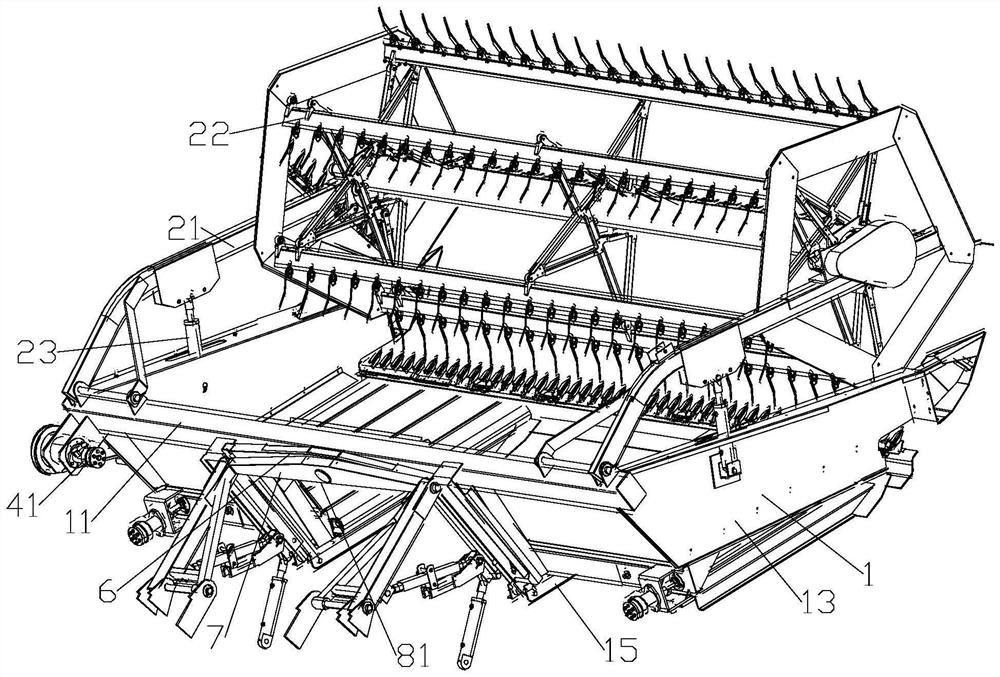

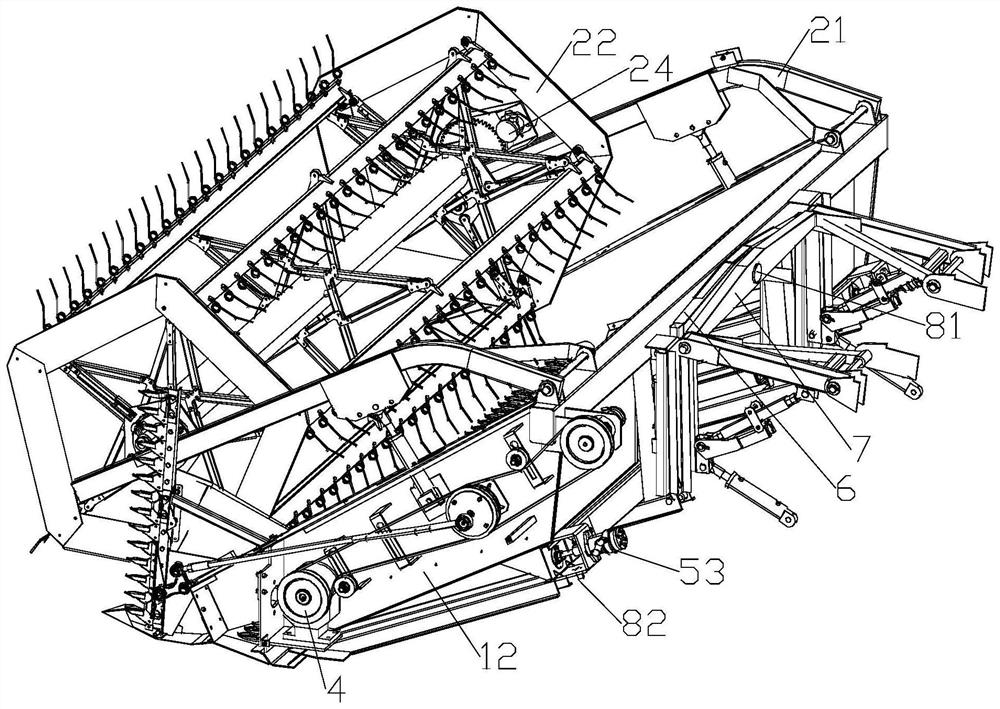

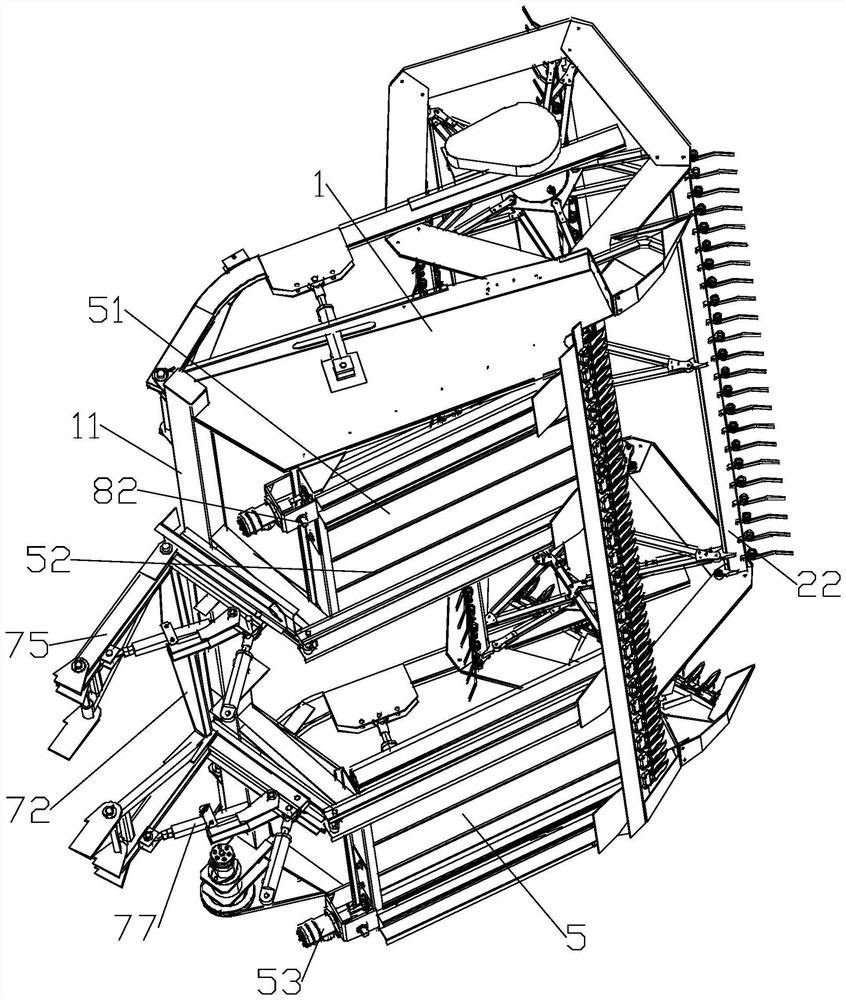

[0048] see Figure 1-3 The full-hydraulic driven high-gap rape mowing platform shown in the center mainly includes the header frame, reel, horizontal cutting knife, vertical cutting knife, left and right inclined conveyor belt conveyor mechanism, quick coupling mechanism, hydraulic drive mechanism, transmission Mechanism, height sensor and controller and other main parts.

[0049] The header frame 1 mainly includes a main beam 11, a left side plate 12 fixed on both sides of the main beam, a right side plate 13, and two vertical beams 14 extending downwards connected to the main beam. The extended bottom beam has longitudinal beams 15 extending forward and backward at the lower part of the bottom beam. The horizontal cutting tool holder is fixed between the left side plate 12 and the front part of the right side plate 13. The front part of the left side plate 12 is fixedly connected to the vertical cutting knife through the left support bar. shelf.

[0050] Two reel brackets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com