Positioning and clamping device for garment processing

A technology for positioning and clamping, clothing, applied in the direction of sewing tools and other directions, can solve the problems of cutting influence, waste of fabric, leveling, etc., to ensure stability and ensure the effect of flattening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

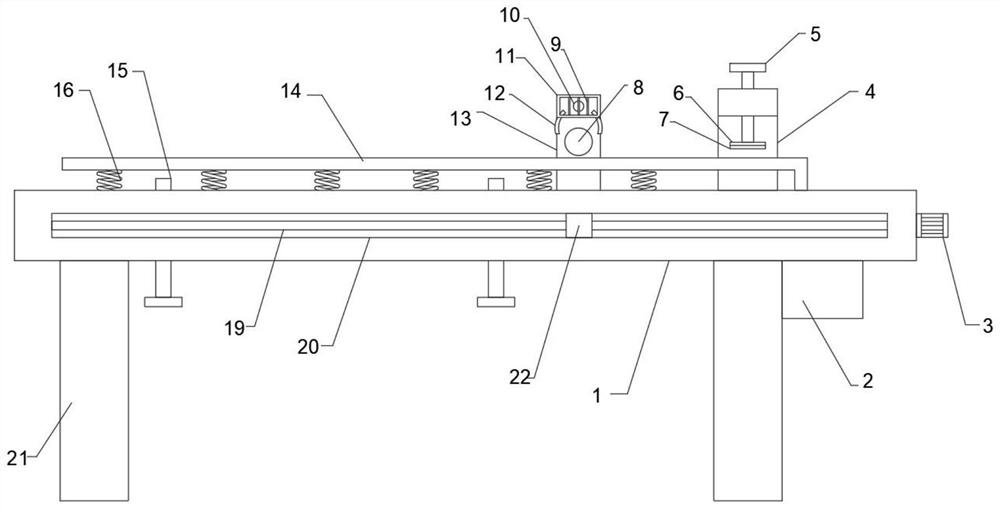

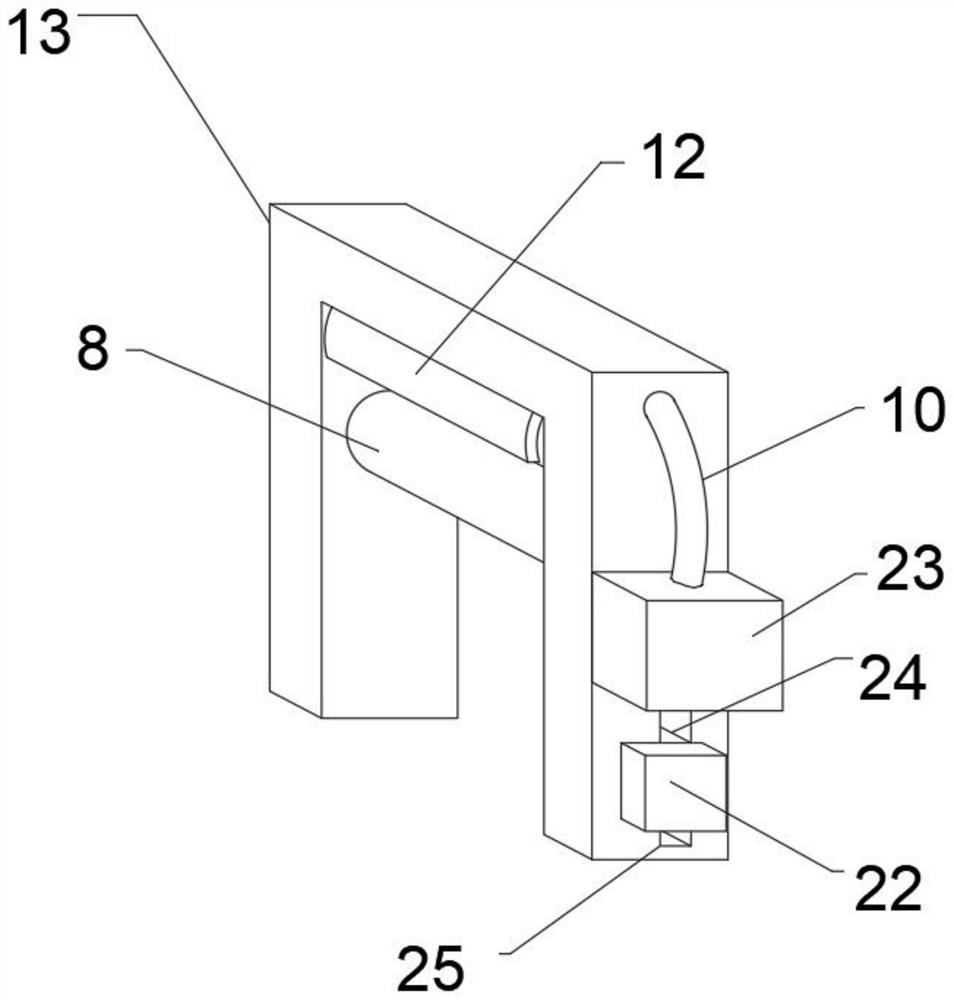

[0023] refer to Figure 1-2 , a positioning and clamping device for garment processing, comprising a workbench 1, the four corners of the bottom outer wall of the workbench 1 are fixedly connected with feet 21, the bottom outer wall of the workbench 1 is fixedly connected with an electric control box 2, and one end of the top outer wall of the workbench 1 is fixed. Connected with a fixed frame 4, the outer wall of the fixed frame 4 is provided with a clamping mechanism, the outer walls of both sides of the workbench 1 are provided with chute 20, the inner wall of the chute 20 is provided with a lateral adjustment mechanism, and the top of the lateral adjustment mechanism is provided with a mobile frame 13, which can move The inner wall of the frame 13 is rotatably connected with pressure rollers 8, and the outer walls on both sides of the mobile frame 13 are provided with height adjustment mechanisms. The bottom of the pressure rollers 8 is provided with a bearing plate 14. Th...

Embodiment 2

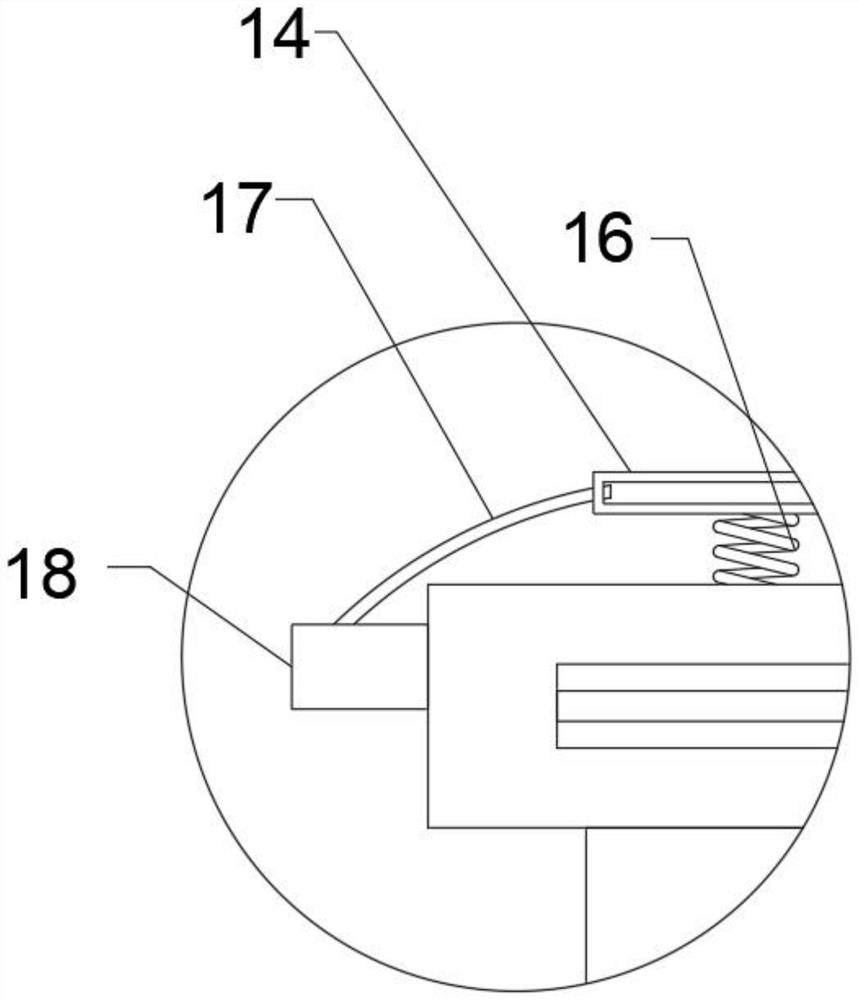

[0031] refer to Figure 2-3 , a positioning and clamping device for garment processing, the bearing plate 14 is set to be hollow, the top outer wall of the bearing plate 14 is provided with a plurality of air holes, the outer wall of one end of the bearing plate 14 is fixedly connected with an air guide hose 17, and the other end of the air guide hose 17 is A vacuum mechanism 18 is fixedly connected, and the vacuum mechanism 18 is fixedly connected with the workbench 1 .

[0032] Working principle: By setting the vacuum mechanism and using the air guide hose 17, the hollow carrier plate 14 can be vacuum-treated, and by setting multiple air holes on the top of the carrier plate 14, the cloth on the top of the carrier plate 14 can be vacuum-adsorbed to ensure that the cloth Stability on the carrier plate 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com