Exhaust assembly and dish washing machine

A technology of components and exhaust ports, which is applied to the parts of dishwashing machines/rinsing machines, etc., can solve the problems of affecting the exhaust effect of the heat exchange tank and the rinsing water tank, potential safety hazards, poor universality of components, etc., and reduce the number of parts. , the effect of improving security and enhancing versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

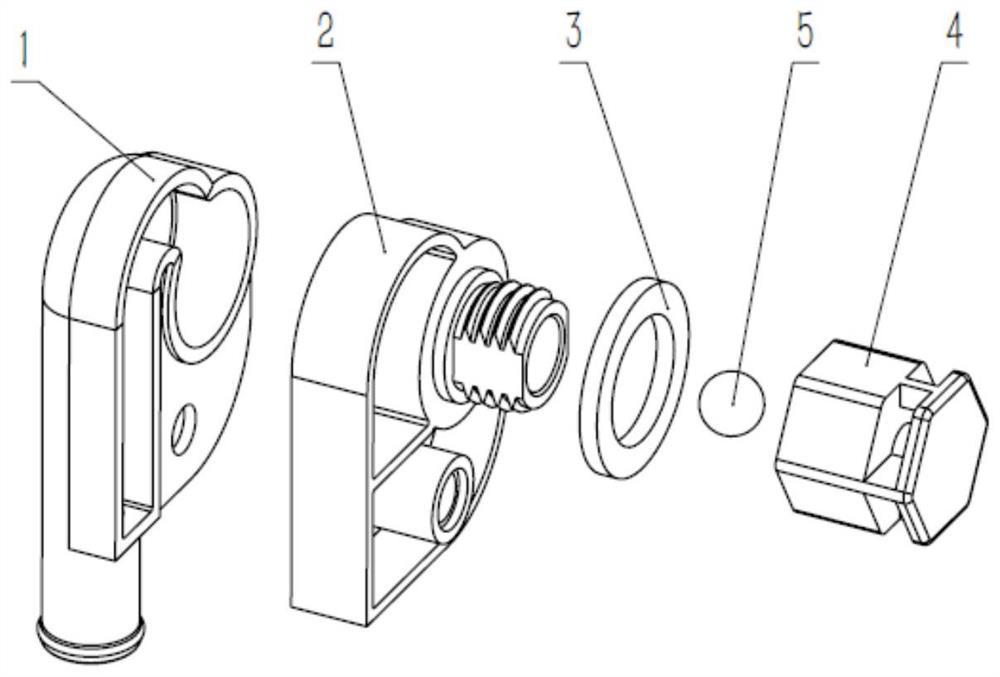

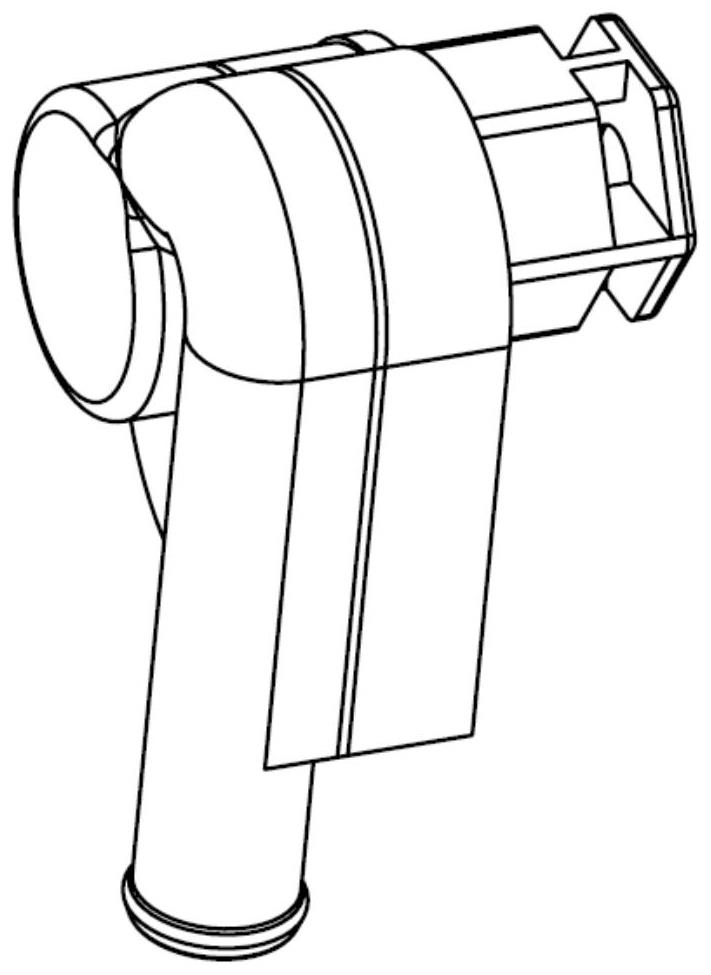

[0027] See Figure 1-3 The exhaust assembly includes an interface member 1, an intermediate member 2, a sealing gasket 3, a nut 4, and a small ball 5.

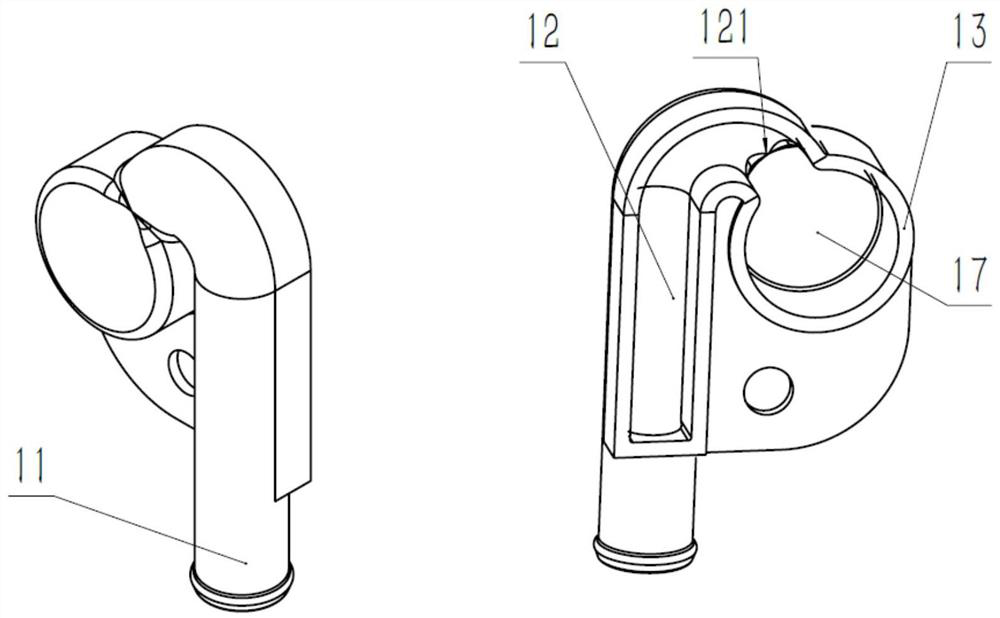

[0028] The interface member 1 includes a tube interface 11, an interface member flow path 12, an interface projection 13, wherein the tube interface 11 is in communication with a device such as a connecting hose (such as a heat transfer box, rinsing tank, drain pipe), in The interface member 1 is formed inside the interface member 1, which includes an inlet segment, a guide section, and an outlet 121 communicating with the tube interface 11. The steam enters the interface member 1 inside the interface portion 1 through the tube interface 11, and flows upward in the inlet segment, and the flow direction is changed through the outlet 121 through the outlet 121. exist image 3 In the inlet segment is a vertical passage, the guide section is a curved channel, both of which are smooth. With curved flow channels, steam entering the interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com