Fire-fighting box facilitating rapid unwinding of pipeline

A fire box and fast technology, applied in fire rescue and other directions, can solve the problems of inconvenience and poor safety, and achieve the effect of improving safety, convenient use and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

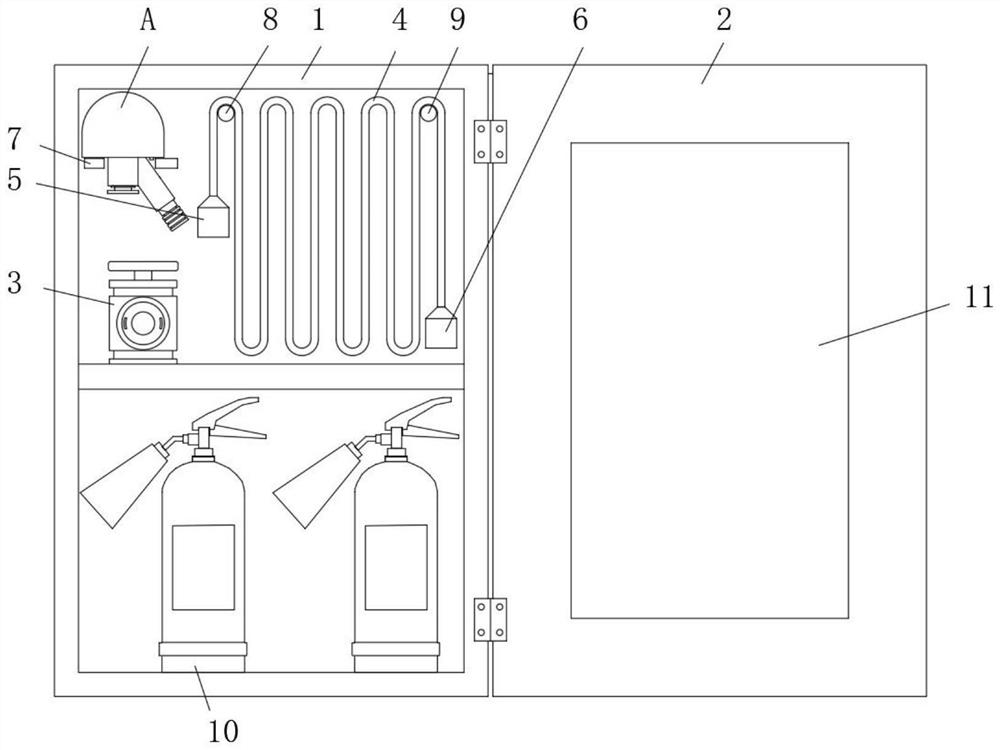

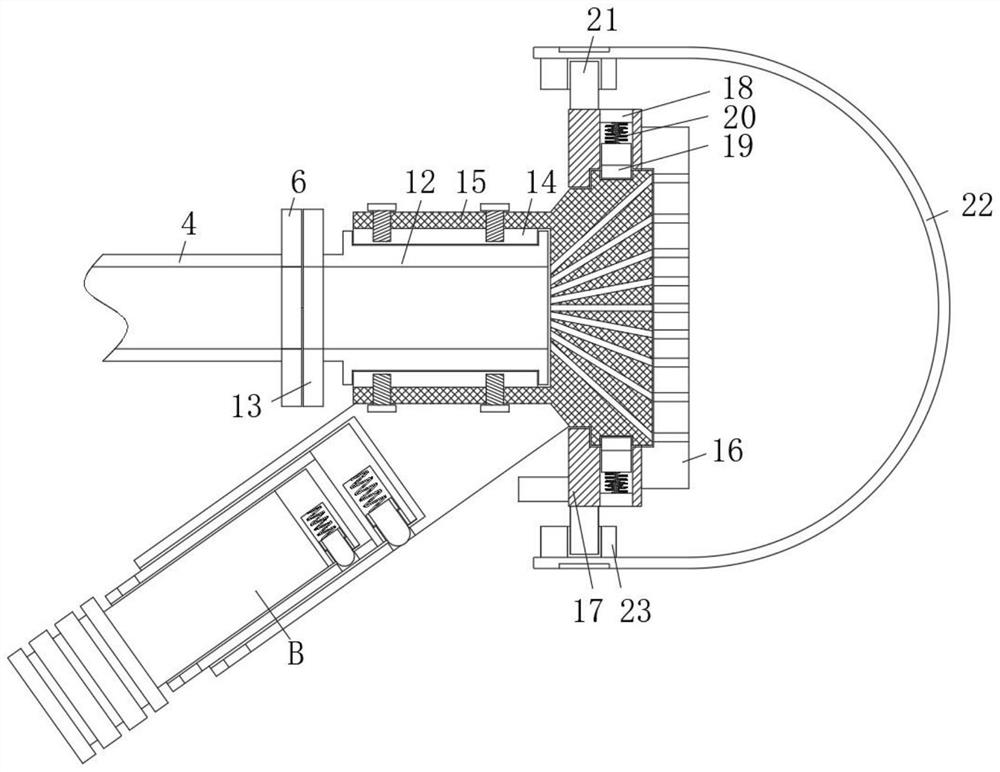

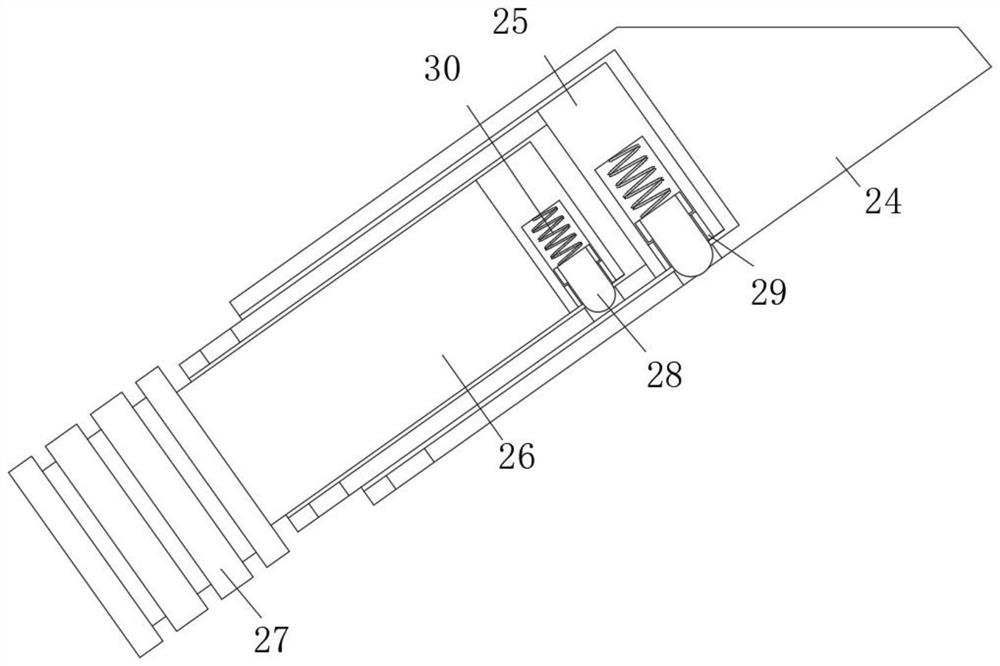

[0026] refer to Figure 1-4 A fire box convenient for rapid unwinding of pipelines comprises a cabinet body 1, wherein a fire hydrant 3, a fire hose 4 and a water outlet joint A are arranged in the cabinet body 1, and the water outlet joint A comprises an inner pipe 12, one end of which is provided with a clamping flange 3 13, the outer side of the inner pipe 12 is provided with a ring groove and is rotatably sleeved with a collar 14, the outer side of the ring body of the collar 14 is fixedly sleeved with a water dispersing base 15, and one end of the water dispersing base 15 has a frustum-shaped structure. The distributor base 15 is provided with a divergent water hole I which is communicated with the inner pipe 12. A quantitative ring 17 is rotatably sleeved on the outer side of the distributor base 15. One end of the quantitative ring 17 is fixedly connected with a distributor plate 16, which is located at one end of the distributor base 15, and the plate body of the distributo...

Embodiment 2

[0030] such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the inner wall of the cabinet body 1 is fixedly provided with a placing seat 7 for placing the water outlet connector A, and a round pin 1 8 and a round pin 2 9 for storing the fire hose 4.

[0031] In this embodiment, it is convenient to store and store the whole fire hose 4, and it is more convenient to take it out in subsequent use.

Embodiment 3

[0033] such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, one end of the fire hose 4 is provided with a clamping flange 1 5 matched with the fire hydrant 3, and the other end of the fire hose 4 and one end of the inner pipe 12 are respectively provided with a clamping flange 2 6 and a clamping flange 3 13 matched with each other.

[0034] In this embodiment, the water outlet joint A is fixedly communicated with the fire hose 4 through the clamping flange 3 13 and the clamping flange 2 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com