Electron-beam floating zone smelting furnace and smelting method

An electron beam and zone technology, applied in self-zone melting method, chemical instruments and methods, crystal growth, etc., can solve the problems of crucible pollution, poor melting effect, and the purity of the final product cannot meet the requirements, etc., and achieve high heating efficiency , temperature gradient is easy to control, saving space and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

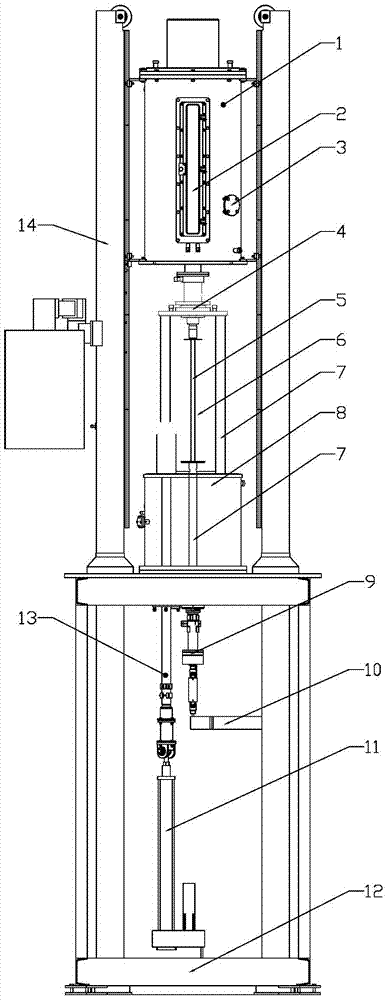

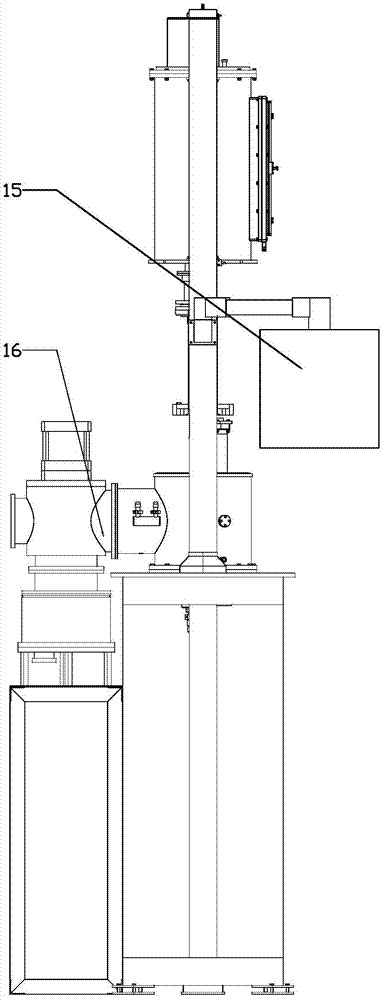

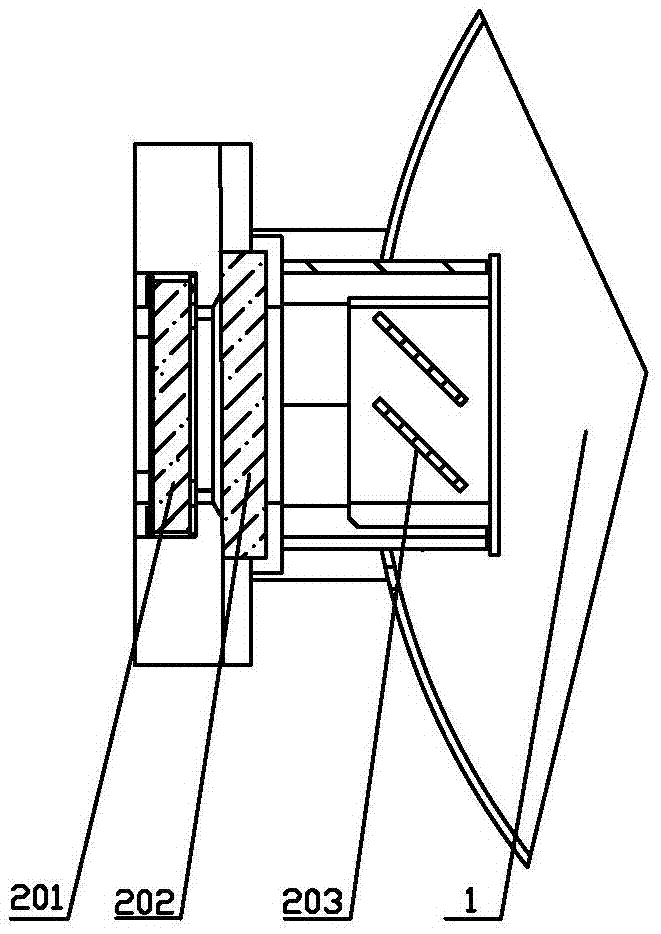

[0045] see figure 1 with figure 2 As shown, the furnace in the electron beam suspension area of the present invention adopts a vertical structure, which mainly includes a furnace body frame, an upper furnace chamber, a lower furnace chamber, a lifting mechanism for the upper furnace chamber, an upper charging mechanism, a lower charging mechanism, an annular electron gun, Gun moving mechanism, material rotating mechanism, high vacuum unit, vacuum observation window, man-machine control panel, argon-filled cooling system, cooling water system. Among them, the gun moving mechanism is driven by a servo electric cylinder, and the material rotating mechanism is driven by a servo motor. Under the action of the corresponding servo controller, the precise movement is realized through the control of the man-machine console, and crystal materials with complete performance are obtained.

[0046]The furnace body of the present invention is composed of an upper furnace chamber and a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com