Telescopic protective spray head for vehicle fire extinguishing

A retractable nozzle technology, applied in fire rescue and other directions, can solve problems such as nozzle damage, attack vehicles, fire extinguishing device failure, etc., to improve fire extinguishing efficiency, prevent damage, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0032] This embodiment provides a retractable protective sprinkler head for vehicle fire extinguishing, which can not only meet the fire fighting requirements of motor vehicles in harsh environments, but also prevent the sprinkler head from being damaged.

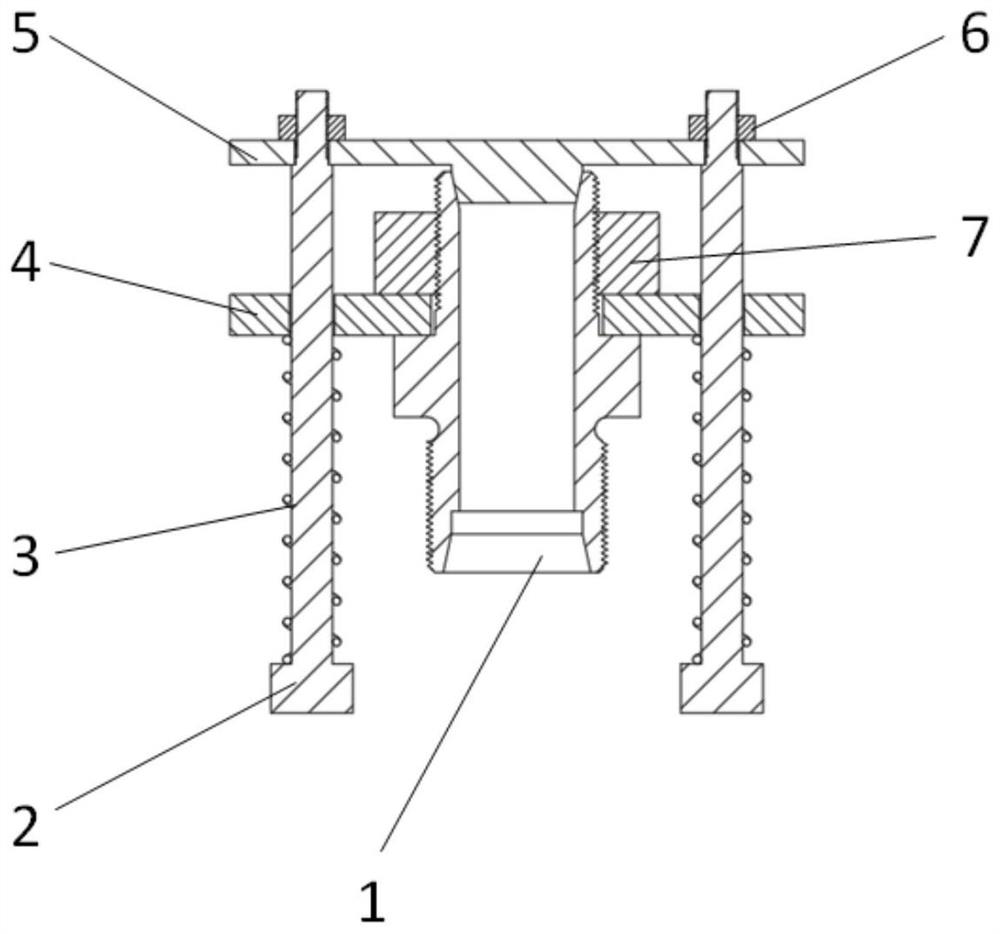

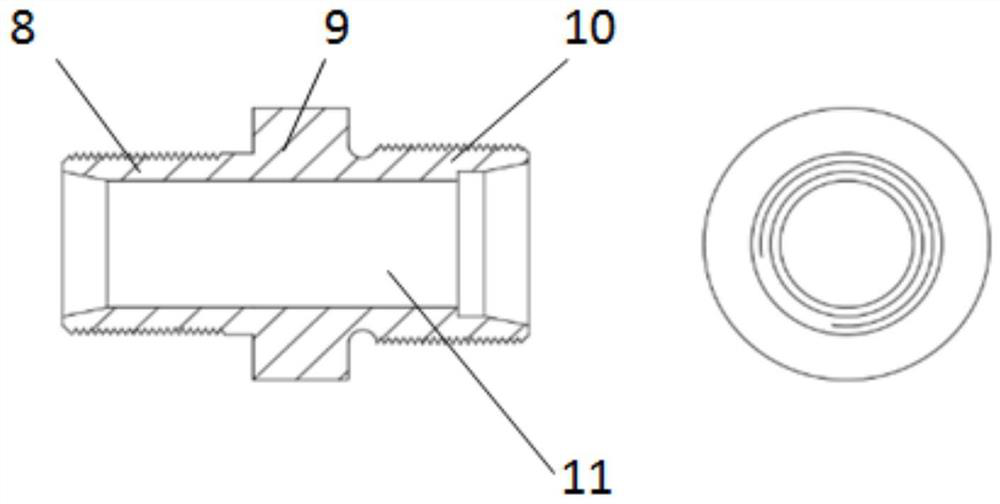

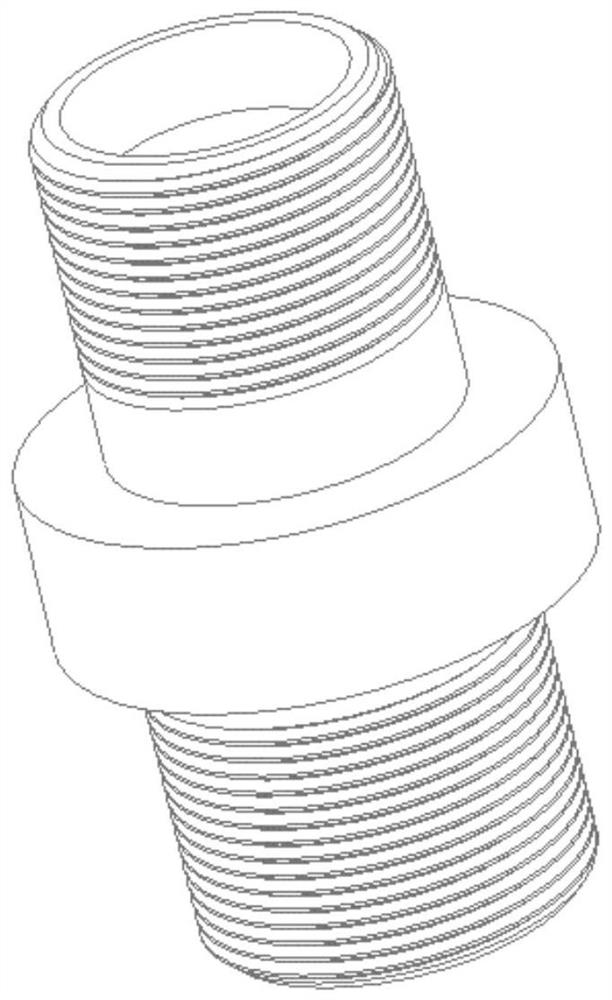

[0033] like figure 1 As shown, the telescopic protective nozzle includes: nozzle 1, guide rod 2, return spring 3, fixed plate 4 and nozzle cover 5; the center of fixed plate 4 is provided with a through hole, which is set on the outer surface of the nozzle end of nozzle 1, And through the fixed plate nut 7, it is pressed on the shoulder provided in the middle of the nozzle 1; the nozzle cover plate 5 is arranged on the nozzle of the nozzle 1, and the other end of the nozzle 1 (the opposite end of the nozzle) is connected with the external fire extinguishing system pipeline The through hole at the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com