Sealed crushing and screening machine

A screening machine and pulverizing section technology, applied in dryers, cleaning hollow objects, food science, etc., can solve the problems of inaccurate sample test results, inability to effectively isolate air, large errors, etc., to improve sample preparation consistency, Reduce the effect of human intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

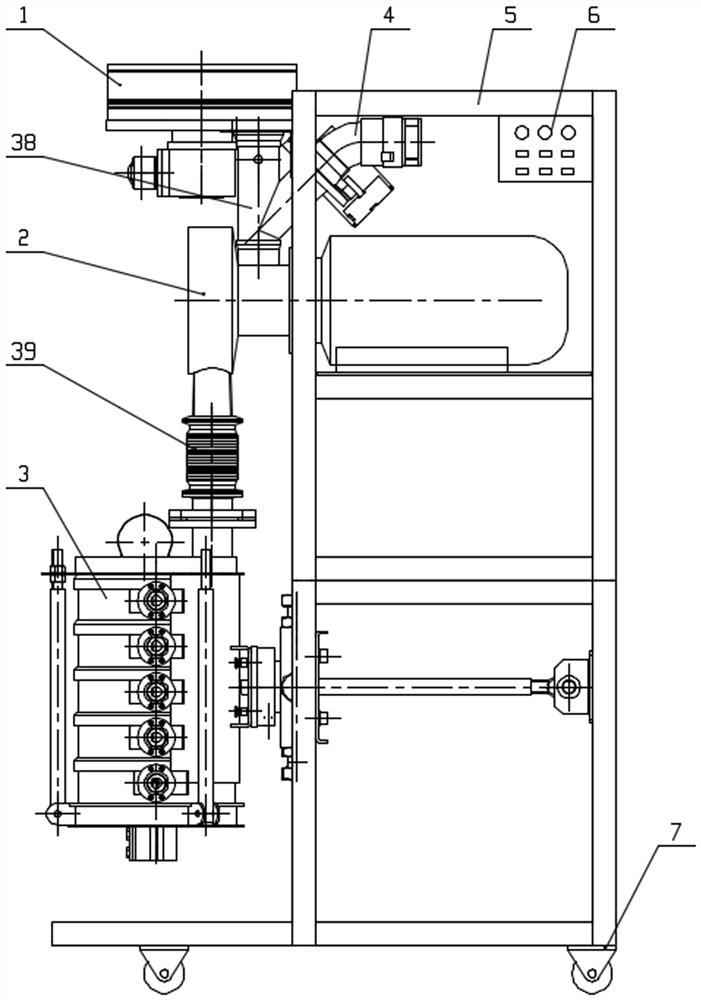

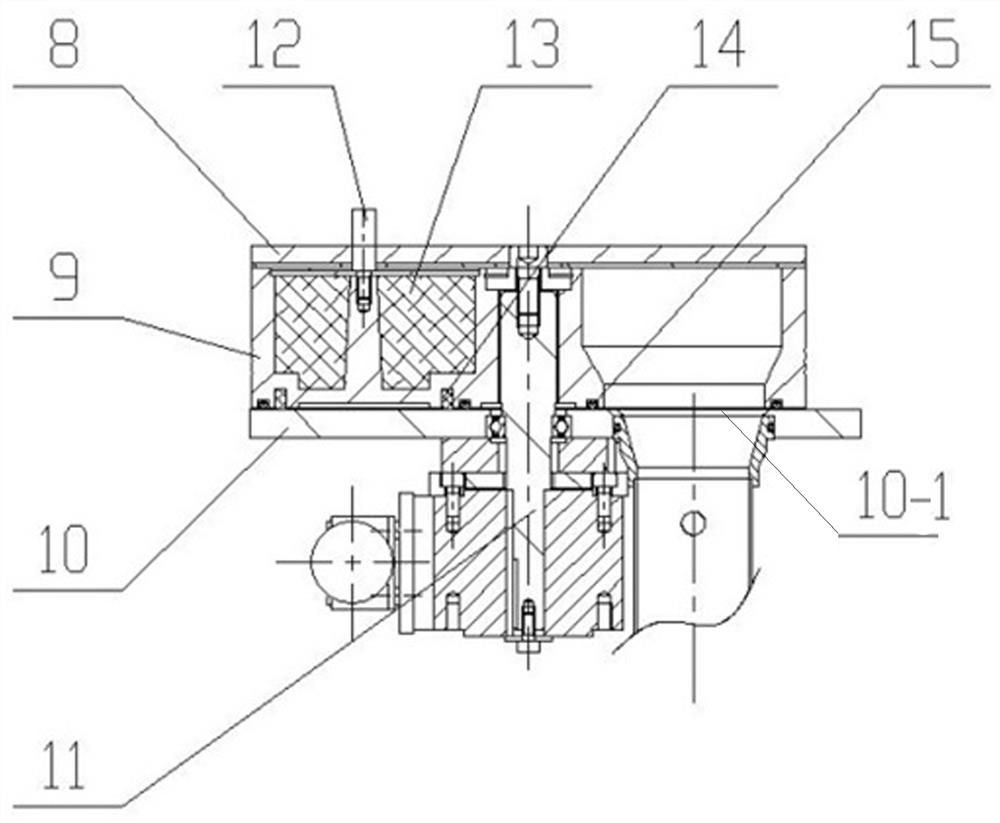

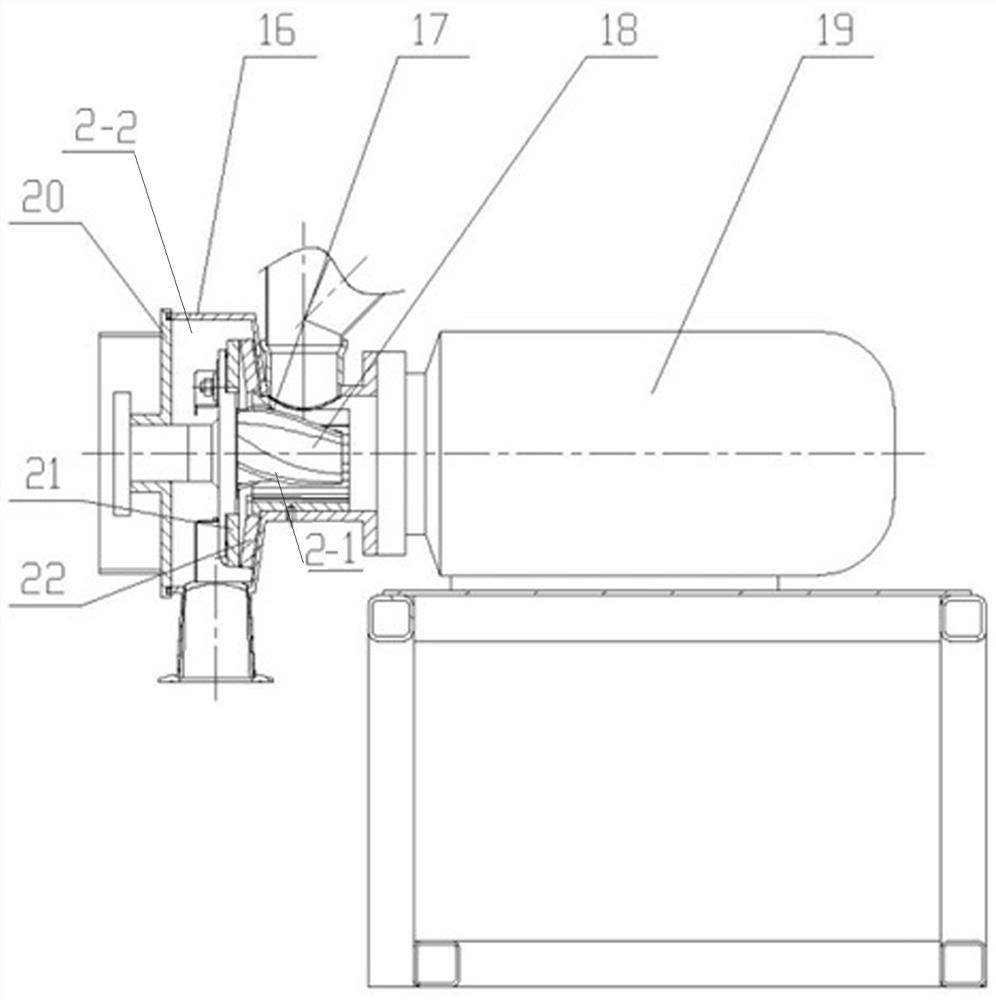

[0044] Such as figure 1 As shown, a sealed crushing and screening machine, the sealing crushing and screening integrated machine of the present invention is mainly composed of an automatic feeder 1 capable of continuous feeding, a mechanical crushing part 2, a vibrating screen part 3, a frame body 5, casters 7, etc. . The automatic feeder 1 of the crushing and screening machine communicates with the crushing part 2 through a connecting pipe 38, the discharge end of the crushing part 2 communicates with the vibrating screen part 3 through a soft connection 39, and the crushing part 2 and the vibrating screen part 3 are fixed on the frame body 5 on. The crushing part 2 and the vibrating screen part 3 of the present invention are fixed on the frame body 5, and other structures can also be fixed on the frame body 5, and the frame body 5 can also be set as a split frame body, which is convenient for disassembly and use, or disassembly and transportation . Caster wheels 7 are arr...

Embodiment 2

[0063] On the basis of Example 1, the automatic crushing and screening integrated machine of the present invention is also equipped with a cleaning and drying system 4, which can realize the cleaning function of the crushing part 2, and the automatic feeder 1 of the crushing and screening machine communicates with the cleaning and drying system 4 Then it is connected with the feeding end of the pulverizing part 2, and now the connecting pipe 38 is a straight pipe 38-1 integrally provided with the structure of an inclined pipe 38-2 with an upwardly inclined angle α of 30-45°, and the straight pipe 38 The upper end of -1 is connected to the injector main body 9, the lower end of the straight pipe 38-1 is connected to the crushing part 2, and the inclined pipe 38-2 is connected to the cleaning and drying system 4.

[0064] Such as figure 1 and 10 As shown, the cleaning and drying system 4 includes an atomizing nozzle, a drying fan 4-4, a drying heater 4-3, and an air valve 4-2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com