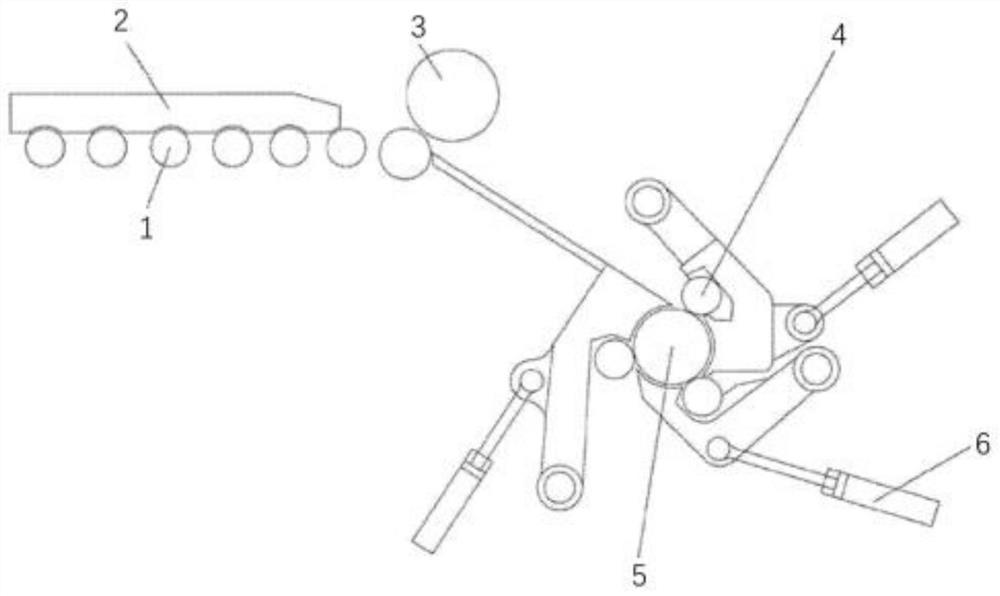

Static calibration method for wrapper roller of hot-rolled strip steel coiler

A technology of hot-rolled strip and calibration method, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of interfering with the collection of the position and pressure of the coiling roll, affecting the calibration accuracy of the roll gap, etc., to reduce empty space. The effect of reducing the burning time, eliminating the large crossover of the tower type, and increasing the sales revenue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

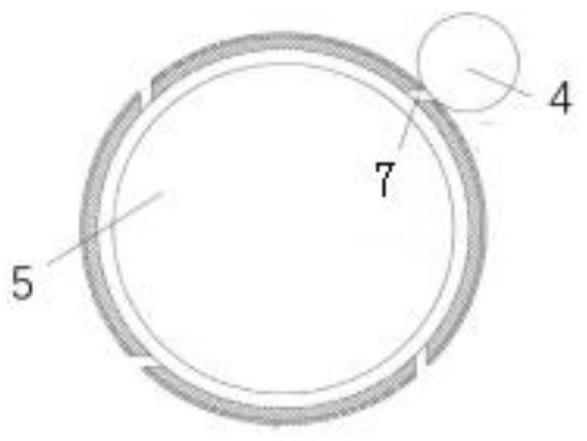

[0032] 1. When the calibration reference force is 50KN, the torque during the expansion process of the mandrel reaches more than 95% of the rated torque, and the output of the servo valve that controls the expansion of the mandrel reaches the upper limit, which obviously increases the wear of the equipment.

[0033] 2. When the calibration reference force is 30KN, during the expansion process of the mandrel, the torque reaches 75-80% of the rated torque, and the output of the servo valve controlling the mandrel expansion reaches 50%, which fully meets the stable operation standard of the equipment, and the roll shape is significantly improved. And there is no indentation on the tape.

[0034] 3. When the calibration reference force is less than or equal to 20KN, the roll shape quality does not improve significantly, and the pressing force of the roll-helping roller cannot meet the process requirements.

[0035] Such as Figure 4 As shown, the present invention adopts static p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com