Aluminum alloy double-sided friction stir welding process

A friction stir welding and welding process technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low welding efficiency, high investment cost of welding tooling, and large welding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

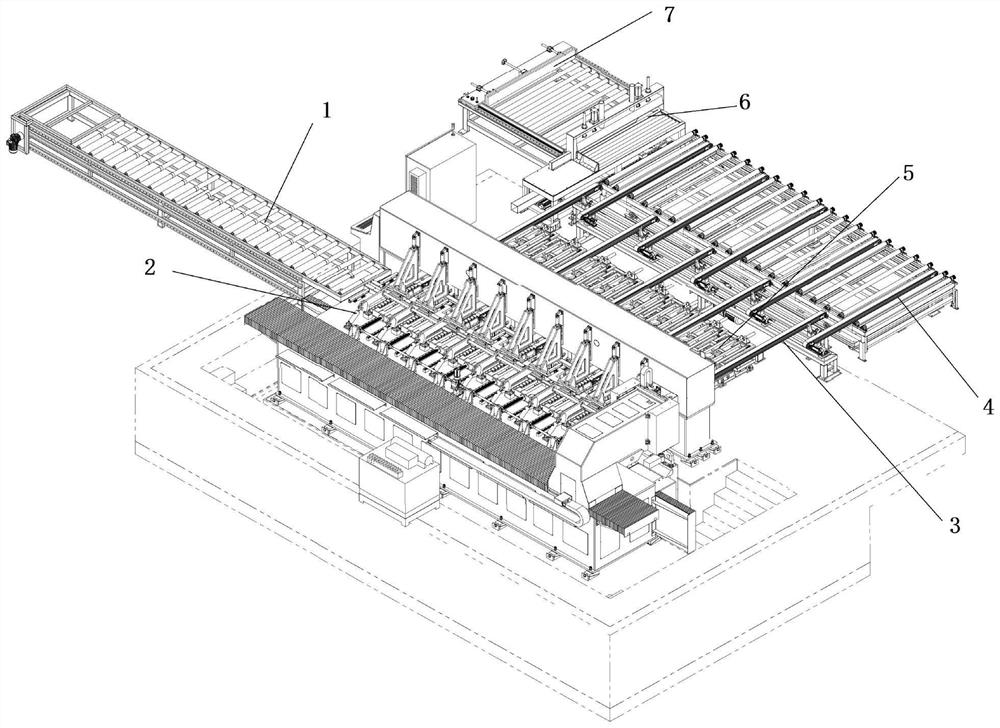

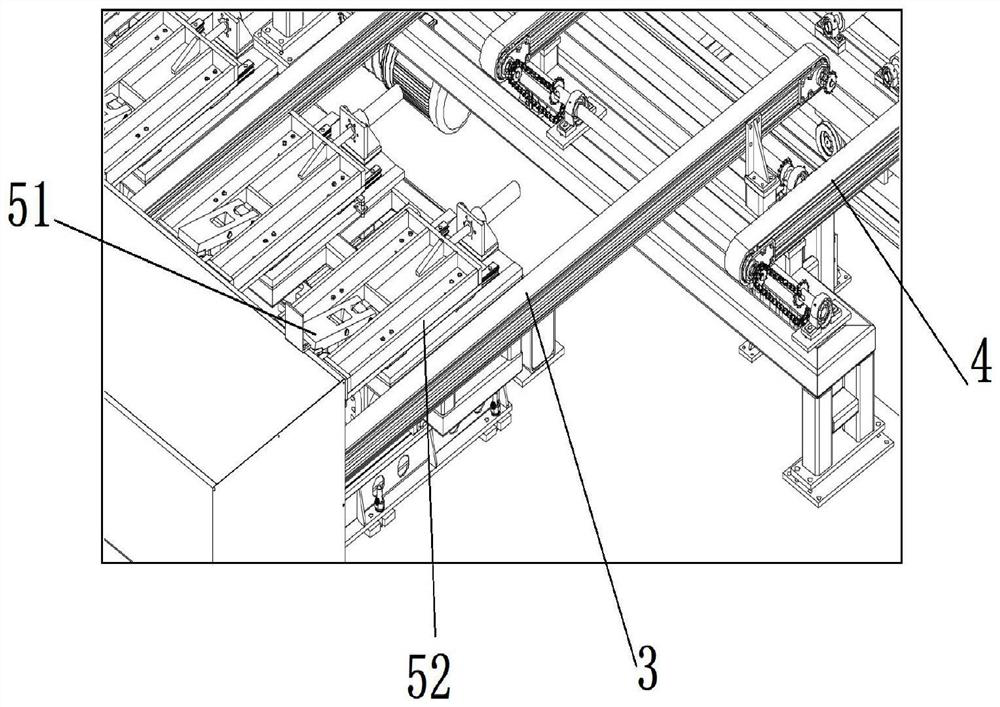

[0078] See Figure 1 to 6 , Specifically Example 1: An aluminum alloy double-sided friction welding welding process, including the following steps:

[0079] Step 1, the aluminum alloy sheet to be welded is delivered to the welding station 2 by the feed carrier 1;

[0080] The welding station 2 is mounted with a first side push mechanism 25 and a second side push mechanism for two blocks to be welded.

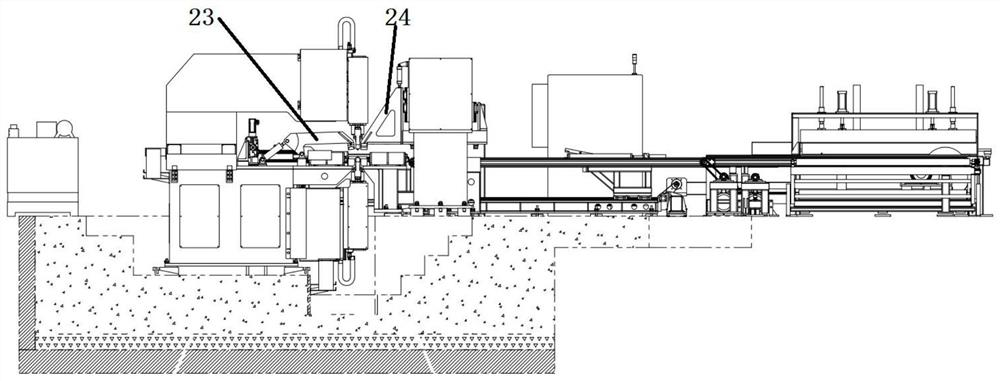

[0081] The welding station 2 is mounted with a first lower pressing mechanism 23 and a second pressing mechanism 24 for separating two pieces of aluminum alloy sheet to be welded, respectively;

[0082] A linear motion welding assembly is also installed on the welding station 2, and the welding assembly includes a frame, and two upper and lower mirror symmetry provided on the frame and a press wheel of the upper mirror symmetry are provided;

[0083] Step 2, the first side push mechanism 25 and the second side push mechanism operate, the two pieces of aluminum alloy sheets to be weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com