A processing and conveying system for medical vehicle parts and its use method

A technology for conveying systems and parts, applied in the field of processing and conveying systems for medical vehicle parts, can solve the problems of huge manpower consumption, low handling efficiency, heavy frame weight, etc., and achieve good cooling effect, low cost and precise cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

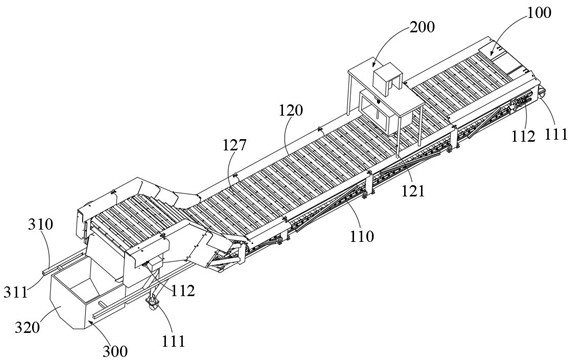

[0050] Such as Figure 1~7As shown, a medical vehicle parts processing delivery system includes a delivery mechanism 100, a welding mechanism 200 arranged at the upper end of the delivery mechanism 100 and a recovery mechanism 300 arranged at one end of the delivery mechanism 100, and the recovery mechanism 300 It includes a fixed rod 310 arranged at one end of the conveying mechanism 100, a recovery box 320 slidably arranged on the fixed rod 310, and several sieve holes 321 provided in the recovery box 320. The length of the fixed rod 310 is A slot 311 is opened in the direction, and an insert 322 adapted to the slot 311 is opened on the side wall of the recovery box 320, wherein the insert 322 is slidably arranged in the slot 311, so that Replace the recovery box 320 .

[0051] Conveying mechanism 100

[0052] The conveying mechanism 100 is suitable for conveying the object to be welded to the welding mechanism 200 , and then conveying the object to be welded to the recove...

Embodiment 2

[0064] On the basis of Embodiment 1, this Embodiment 2 also provides a medical vehicle parts processing and conveying system and its use method, wherein a medical vehicle parts processing and conveying system is the same as Embodiment 1, and will not be repeated here. . A specific method of using a medical vehicle parts processing and conveying system is as follows:

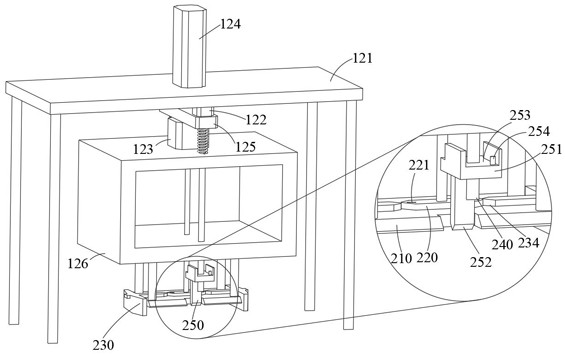

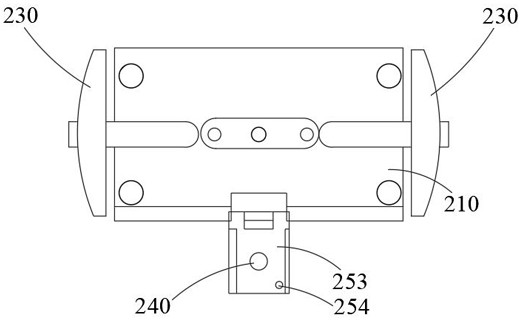

[0065] S1. The conveyor belt 120 transports the object to be welded to the bottom of the welding mechanism 200, and the crimping plate 210 moves downward to compress the object to be welded;

[0066] S2. When the waist-shaped plate 220 rotates until the waist-shaped plate 220 pushes the shear plate 250 to squeeze the air bag 1, the air jet from the blowing port is suitable for cleaning the redundant fins on the object to be welded , at the same time, the extrusion plate 230 moves toward the waist plate 220 to clamp and fix the object to be welded, and the shear plate 250 moves downward to remove excess fins on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com