Modified asphalt waterproof coiled material and preparation process thereof

A technology of waterproof membrane and modified asphalt, which is applied in metal processing and other directions, and can solve the problems of not being able to deal with the waterproofing of rectangular pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

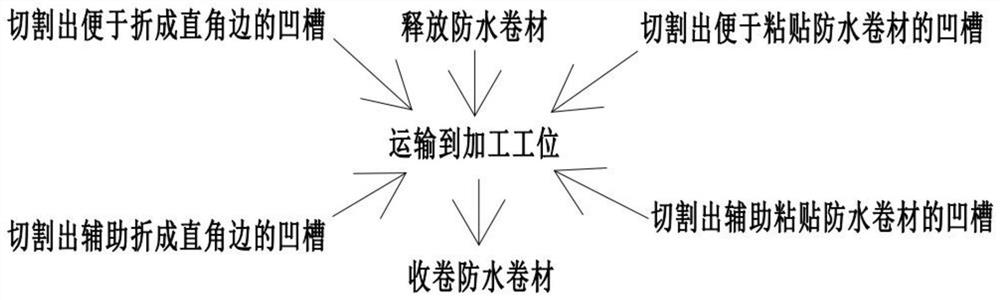

[0023] refer to figure 1 , detailing the process of preparing modified bitumen waterproof membrane:

[0024] A preparation process of modified bitumen waterproof coiled material, the process comprises the following steps:

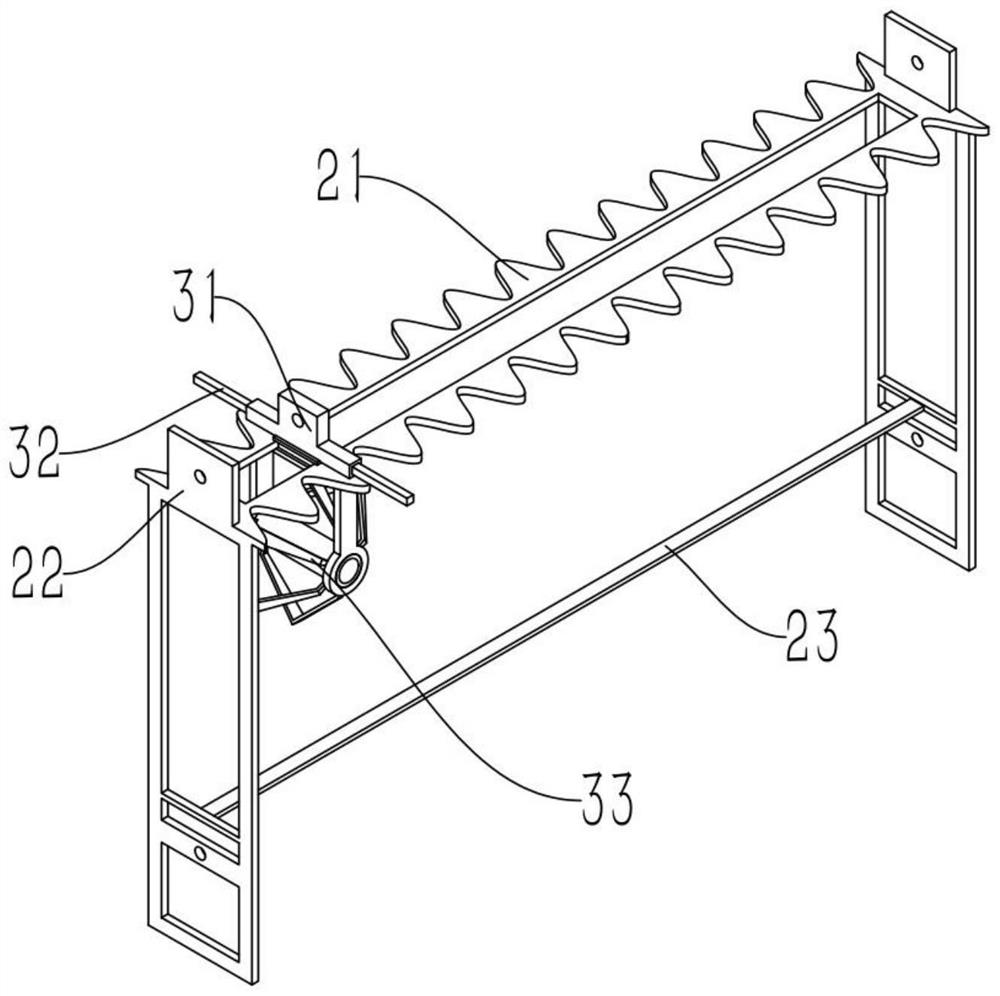

[0025] Step 1: Prepare and release the formed base material; set up a release mechanism for the base material to continuously release the base material.

[0026] Step 2: Stop the basic material at the processing station and stop the transportation; transport the basic material to the processing station and stop the transportation of the basic material, so as to facilitate the processing of the basic material.

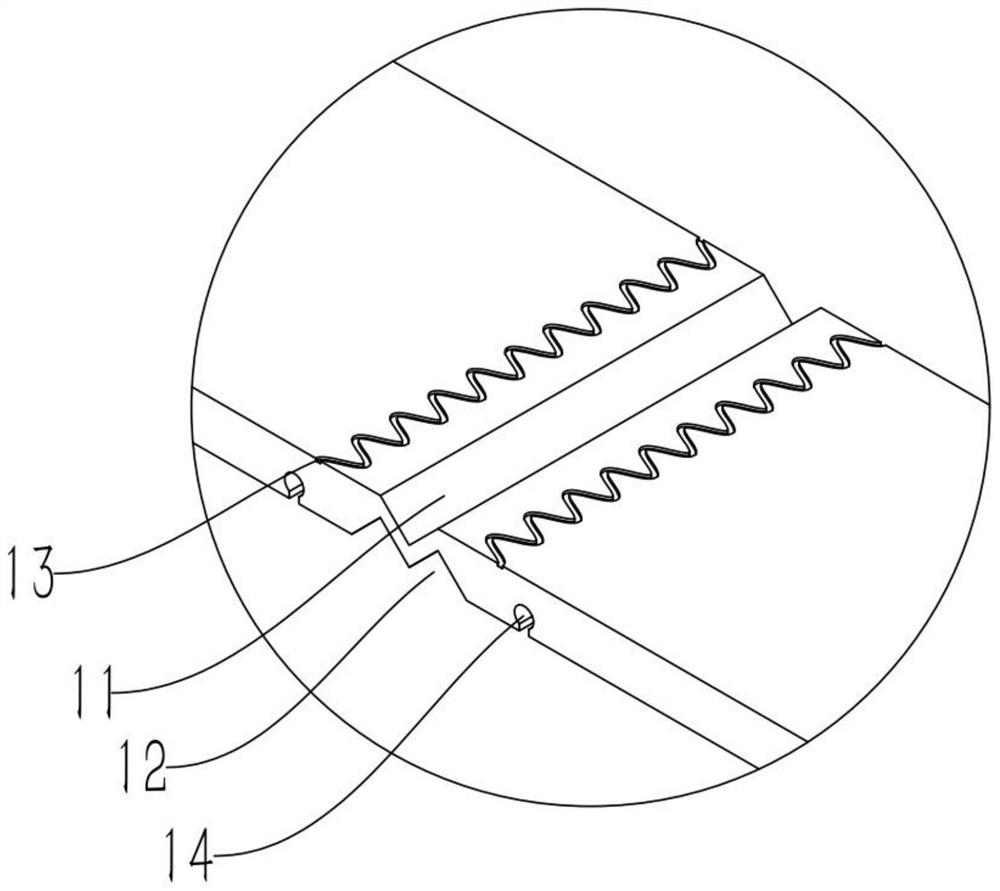

[0027] Step 3: Process the base material into hemming grooves 11, two auxiliary grooves 12, two serpentine grooves 13 and two clamping grooves 14. The hemming grooves 11 are at right angles, which is convenient for folding The base material on the side is folded with each other to form a right angle and tightly fit on the right-angled side of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com